Dairy farming on the outskirts of Blessington, Co Wicklow, Ben and Andy Hamilton year found themselves in the market for a new telescopic loader this year.

The Hamiltons clocked up 2,500 hours in just two years using the farm’s previous workhorse that was a 1998 JCB TM200 as result of increasing cow numbers.

The decision to either spend a considerable amount of money overhauling the JCB or to replace it with a new machine had to be made.

One of the jobs the 3080T is used for is pushing in zero-grazed grass.

After some thought, it was decided a new Weidemann 3080T would replace the 23-year-old JCB.

Five years ago, Ben made the decision to return home, farming full-time in partnership with his father Andy.

Ben Hamilton, Blessington Co Wicklow.

Since then, Ben’s main focus has been on increasing production, with a focus on good grassland utilisation and management.

With the farm being quite fragmented, he felt the best way to increase cow numbers was to go down the route of zero-grazing grass on outfarms and taking it back to the home farm.

Ben finds that the 3080T punches well above its weight.

Today, the family milks 100 cows with the intention of increasing this to 140 in the coming years.

Aside from feeding zero-grazed grass, 1,000 bales of silage are made annually. There is no slatted tank on the farm, so yards and passages need to be scraped on a daily basis. Therefore, a loader is a necessary tool on the farm all year.

Ben noted that during the winter when cows are housed that the loader may be in use for as much as six or seven hours daily.

Buying new

Unsure whether to buy new or not, Ben sat down last winter and ran the numbers comparing new with secondhand. He came to a decision to buy new.

The 3080T has a maximum lift capacity of 2,815kg or 1,554kg at full extension.

“We knew the JCB was at the age where if it was to continue doing the work required, then it would need up to €15,000 spent on it sooner rather than later, more than what it was worth fixed up.

“The interest rate on a new machine was more appealing over secondhand. The depreciation and interest being tax-deductible too is a help.

“Aside from that, the peace of mind having reliability and warranty was a major attraction too.

“For example, the likelihood of a hydraulic hose bursting due to wear was going to be a lot lower and the subsequent down time that goes with it too. Therefore, running costs tend to be much more predictable,” explained Ben.

Access to the engine bay and cooling pack cannot be faulted.

The Hamiltons required a compact machine that would be easily manoeuvred for scraper duties in the cubicle sheds and in the feeding passage pushing in zero-grazed grass or feeding out silage bales.

With no loyalty to any particular brand, Ben and Andy looked at a number of machines including Schaffer, Manitou and JCB.

The duo agreed that the Weidemann stood out for number of reasons, primarily for its design and built quality.

Ben said: “Having looked at other brands and then seeing the Weidemann, it instantly appealed to us.

“The thickness of the steel used seemed to be ahead of the rest. Another thing was the strength and simplicity of the pivot point which is fully greasible.

“Things like the diesel and hydraulic oil tank location in the rear ballast made practical sense too, unlike under the boom on one other machine.”

The cab may not be the most spacious but its layout is clean and simple.

These features were the major attractions in going down the route of a Weidemann alongside the willingness of Weidemann dealer Byrne Machinery to strike a deal. The 3080T was the model that fitted both the bill and the budget best.

Engine and transmission

The 3080T is fitted with a 75hp (55.4kW) four-cylinder Deutz Stage V engine. So far, the power of the loader has been plentiful for the Hamiltons.

“The only time I’d feel the engine under pressure is at full speed on the road transporting bales back to the yard, especially when meeting a hill. It’s easy to forget it’s 75hp given its liveliness around the yard.”

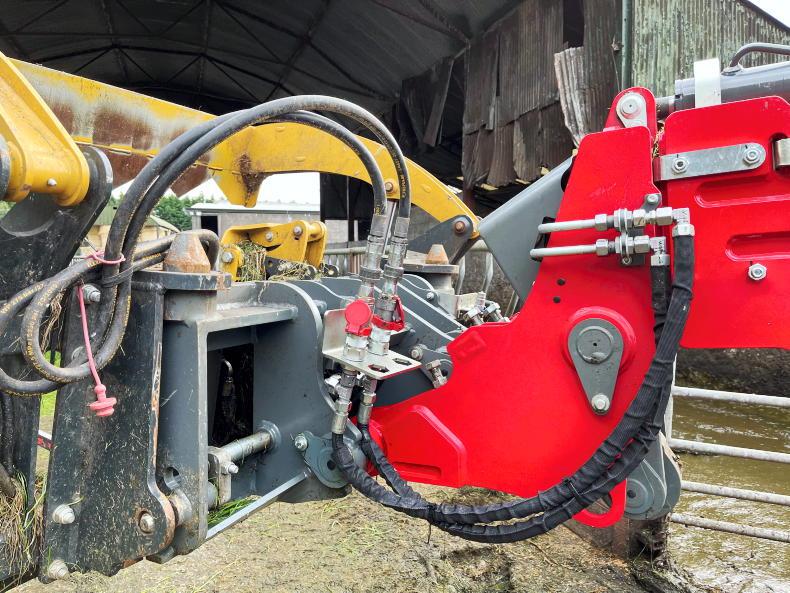

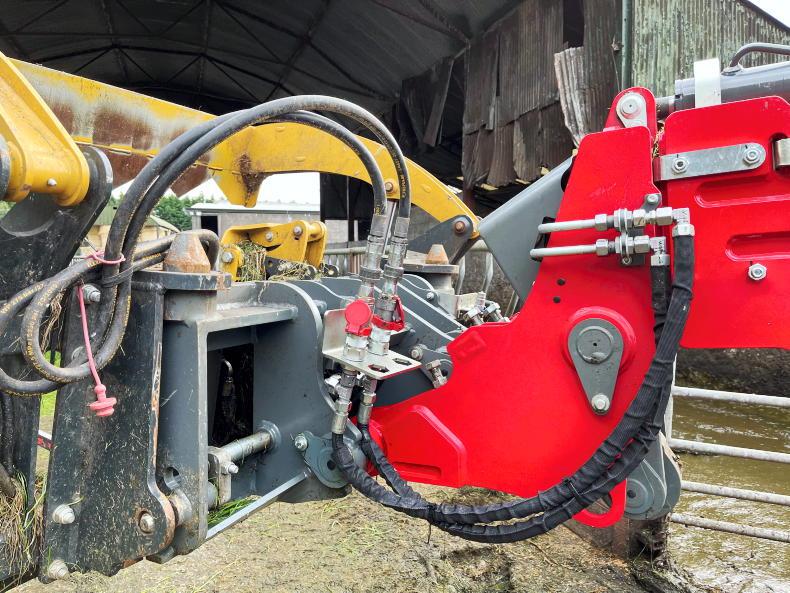

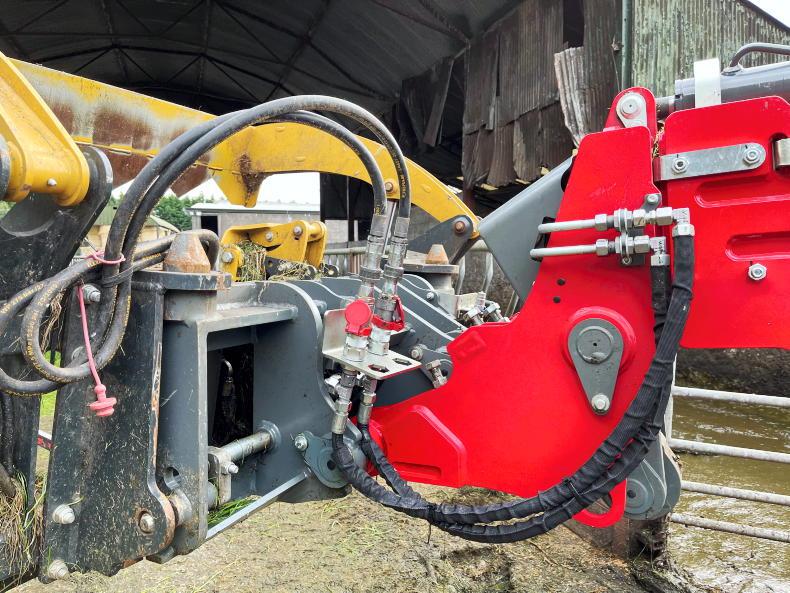

The loader is fitted with the Matbro-type pin and cone headstock.

Keeping the wheels in motion is a hydrostatic transmission. Ben explained that it offers two ranges - low and high - with a maximum speed of 35km/h, which he feels is plenty for the 75hp engine.

“The concept of a hydrostatic transmission appealed to me from the get-go. I rather the fact the inching pedal restricts oil flow to the hydrostat – reducing forward speed while maintain engine revs over the system used in a powershift loader,” Ben added.

Also appealing was that the Weidemann was offered on 550/45 R22.5 tyres, which were wider than the wheels on some of the other brands while keeping a similar overall machine width.

Cab and controls

They were quick to compliment the low pivot height of the boom which leaves for much better visibility compared with other brands.

The 3080T is fitted with 550 tyres and ZF axles.

“Visibility can’t be faulted. The rear counterweight is pretty much flush with the bonnet and each of the four mudguards are easily seen from the seat, so nothing is hidden. The wing mirrors are within the overall width of the loader, so they’re not going to be damaged easily,” Ben added

All major functions, including the directional shuttle, headstock movements, telescoping of the boom and third service functions, are carried out through the joystick.

Additionally, there is a switch to the back of the joystick which, if pressed, completely locks up both the front and rear differentials.

Unlike a number of competitors, Weidemann uses open differentials as opposed to a limited slip differentials (LSD).

All grease points are very accessible.

This way both the front and rear differential can be fully locked up for maximum traction instead of partially locked up with an LSD.

Although the cab is not be the most spacious on the market, access is very good. Ben opted to have the handler fitted with an air seat, as opposed to the standard sprung seat for improved comfort.

A unique feature offered by Weidemann is the ability to tilt the cab over to one side. Ben feels that this shows the German manufacturer’s degree of forward thinking.

The ability to tilt the cab to one side is a unique feature.

Simply open two 24mm nuts and start pumping the built-in jack and within two minutes the cab is tilted.

Combined with the wide-opening bonnet, this offers considerable access to the engine, hydraulic system and electronic circuits if needs be.

Earlier this summer Ben used the handler to push up first-cut silage for a neighbour.

Ben said it proved capable given that the pit wasn’t steep, although he agreed it would be out of its depth if bought solely for such task given its size and capacity.

With over 300 hours clocked so far, Ben and Andy feel they made the right decision buying the Weidemann. Although larger than the previous TM 200, the 3080T is much more manoeuvrable, which they put down to the good steering lock.

Ben summarised the 3080T: “It’s a very operator-friendly machine with good hydraulic performance, reach and good lift capacity for its size. So far, we couldn’t fault it.”

The strength in the boom and low pivot point appealed to the Hamiltons.

When the time comes to upgrade again, Ben said that the additional capacity of the 5080T would be a great comfort for certain tasks – although currently more of a desire than a need, he added.

Ben is impressed by the design and build quality of the Weidemann.

Engine: 2.9l four-cylinder Deutz.Horsepower: 75hp (55.4kW).Transmission: 30km/h two speed hydrostatic.Hydraulics: 83l/min.Lift capacity: 2,250kg.Max reach (headstock pivot pins): 5m.Fuel tank: 82l.Tyres: 550/45 R22.5.Unladen weight: 5,400kg.Starting price: €75,435 plus VAT.

The low boom pivot point means visibility is not hindered.

Dairy farming on the outskirts of Blessington, Co Wicklow, Ben and Andy Hamilton year found themselves in the market for a new telescopic loader this year.

The Hamiltons clocked up 2,500 hours in just two years using the farm’s previous workhorse that was a 1998 JCB TM200 as result of increasing cow numbers.

The decision to either spend a considerable amount of money overhauling the JCB or to replace it with a new machine had to be made.

One of the jobs the 3080T is used for is pushing in zero-grazed grass.

After some thought, it was decided a new Weidemann 3080T would replace the 23-year-old JCB.

Five years ago, Ben made the decision to return home, farming full-time in partnership with his father Andy.

Ben Hamilton, Blessington Co Wicklow.

Since then, Ben’s main focus has been on increasing production, with a focus on good grassland utilisation and management.

With the farm being quite fragmented, he felt the best way to increase cow numbers was to go down the route of zero-grazing grass on outfarms and taking it back to the home farm.

Ben finds that the 3080T punches well above its weight.

Today, the family milks 100 cows with the intention of increasing this to 140 in the coming years.

Aside from feeding zero-grazed grass, 1,000 bales of silage are made annually. There is no slatted tank on the farm, so yards and passages need to be scraped on a daily basis. Therefore, a loader is a necessary tool on the farm all year.

Ben noted that during the winter when cows are housed that the loader may be in use for as much as six or seven hours daily.

Buying new

Unsure whether to buy new or not, Ben sat down last winter and ran the numbers comparing new with secondhand. He came to a decision to buy new.

The 3080T has a maximum lift capacity of 2,815kg or 1,554kg at full extension.

“We knew the JCB was at the age where if it was to continue doing the work required, then it would need up to €15,000 spent on it sooner rather than later, more than what it was worth fixed up.

“The interest rate on a new machine was more appealing over secondhand. The depreciation and interest being tax-deductible too is a help.

“Aside from that, the peace of mind having reliability and warranty was a major attraction too.

“For example, the likelihood of a hydraulic hose bursting due to wear was going to be a lot lower and the subsequent down time that goes with it too. Therefore, running costs tend to be much more predictable,” explained Ben.

Access to the engine bay and cooling pack cannot be faulted.

The Hamiltons required a compact machine that would be easily manoeuvred for scraper duties in the cubicle sheds and in the feeding passage pushing in zero-grazed grass or feeding out silage bales.

With no loyalty to any particular brand, Ben and Andy looked at a number of machines including Schaffer, Manitou and JCB.

The duo agreed that the Weidemann stood out for number of reasons, primarily for its design and built quality.

Ben said: “Having looked at other brands and then seeing the Weidemann, it instantly appealed to us.

“The thickness of the steel used seemed to be ahead of the rest. Another thing was the strength and simplicity of the pivot point which is fully greasible.

“Things like the diesel and hydraulic oil tank location in the rear ballast made practical sense too, unlike under the boom on one other machine.”

The cab may not be the most spacious but its layout is clean and simple.

These features were the major attractions in going down the route of a Weidemann alongside the willingness of Weidemann dealer Byrne Machinery to strike a deal. The 3080T was the model that fitted both the bill and the budget best.

Engine and transmission

The 3080T is fitted with a 75hp (55.4kW) four-cylinder Deutz Stage V engine. So far, the power of the loader has been plentiful for the Hamiltons.

“The only time I’d feel the engine under pressure is at full speed on the road transporting bales back to the yard, especially when meeting a hill. It’s easy to forget it’s 75hp given its liveliness around the yard.”

The loader is fitted with the Matbro-type pin and cone headstock.

Keeping the wheels in motion is a hydrostatic transmission. Ben explained that it offers two ranges - low and high - with a maximum speed of 35km/h, which he feels is plenty for the 75hp engine.

“The concept of a hydrostatic transmission appealed to me from the get-go. I rather the fact the inching pedal restricts oil flow to the hydrostat – reducing forward speed while maintain engine revs over the system used in a powershift loader,” Ben added.

Also appealing was that the Weidemann was offered on 550/45 R22.5 tyres, which were wider than the wheels on some of the other brands while keeping a similar overall machine width.

Cab and controls

They were quick to compliment the low pivot height of the boom which leaves for much better visibility compared with other brands.

The 3080T is fitted with 550 tyres and ZF axles.

“Visibility can’t be faulted. The rear counterweight is pretty much flush with the bonnet and each of the four mudguards are easily seen from the seat, so nothing is hidden. The wing mirrors are within the overall width of the loader, so they’re not going to be damaged easily,” Ben added

All major functions, including the directional shuttle, headstock movements, telescoping of the boom and third service functions, are carried out through the joystick.

Additionally, there is a switch to the back of the joystick which, if pressed, completely locks up both the front and rear differentials.

Unlike a number of competitors, Weidemann uses open differentials as opposed to a limited slip differentials (LSD).

All grease points are very accessible.

This way both the front and rear differential can be fully locked up for maximum traction instead of partially locked up with an LSD.

Although the cab is not be the most spacious on the market, access is very good. Ben opted to have the handler fitted with an air seat, as opposed to the standard sprung seat for improved comfort.

A unique feature offered by Weidemann is the ability to tilt the cab over to one side. Ben feels that this shows the German manufacturer’s degree of forward thinking.

The ability to tilt the cab to one side is a unique feature.

Simply open two 24mm nuts and start pumping the built-in jack and within two minutes the cab is tilted.

Combined with the wide-opening bonnet, this offers considerable access to the engine, hydraulic system and electronic circuits if needs be.

Earlier this summer Ben used the handler to push up first-cut silage for a neighbour.

Ben said it proved capable given that the pit wasn’t steep, although he agreed it would be out of its depth if bought solely for such task given its size and capacity.

With over 300 hours clocked so far, Ben and Andy feel they made the right decision buying the Weidemann. Although larger than the previous TM 200, the 3080T is much more manoeuvrable, which they put down to the good steering lock.

Ben summarised the 3080T: “It’s a very operator-friendly machine with good hydraulic performance, reach and good lift capacity for its size. So far, we couldn’t fault it.”

The strength in the boom and low pivot point appealed to the Hamiltons.

When the time comes to upgrade again, Ben said that the additional capacity of the 5080T would be a great comfort for certain tasks – although currently more of a desire than a need, he added.

Ben is impressed by the design and build quality of the Weidemann.

Engine: 2.9l four-cylinder Deutz.Horsepower: 75hp (55.4kW).Transmission: 30km/h two speed hydrostatic.Hydraulics: 83l/min.Lift capacity: 2,250kg.Max reach (headstock pivot pins): 5m.Fuel tank: 82l.Tyres: 550/45 R22.5.Unladen weight: 5,400kg.Starting price: €75,435 plus VAT.

The low boom pivot point means visibility is not hindered.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: