Having founded a factory near the site of the former Wheatley Hall, in Doncaster, South Yorkshire in 1938, International Harvester Great Britain (IHGB) began tractor production at the plant in 1949, before later opening a second Doncaster facility, at Carr Hill, followed by a third UK factory, in nearby Bradford.

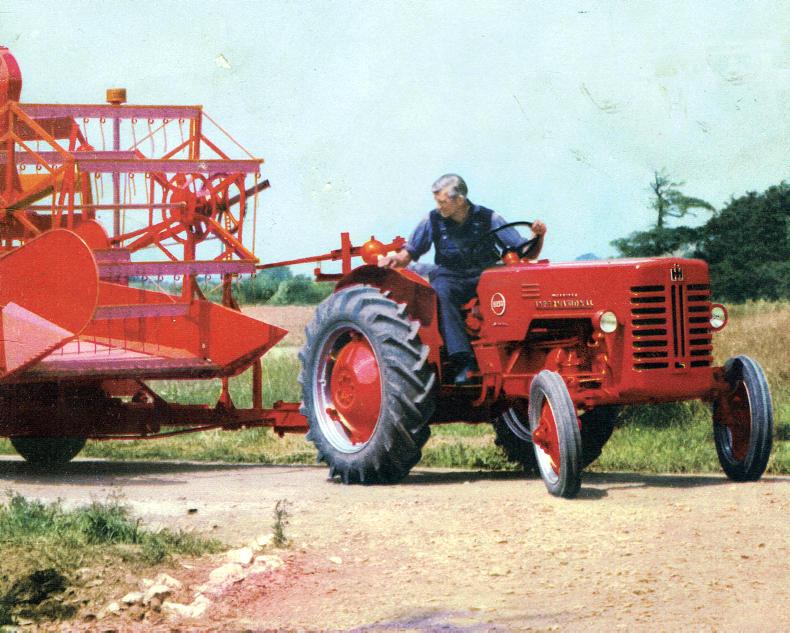

The first UK-produced IH tractor, based on the US-designed Farmall M, debuted in 1949, while in 1954 came the BWD-6, a European version of the American WD-6. By 1955, though, IHGB engineers had designed a range aimed at British and Irish farm needs. Built in the Bradford factory, the smallest of these was the B-250, launched at the 1955 Royal Smithfield Show in London’s Earl’s Court.

Designed to compete with the Fordson Dexta and Massey-Ferguson 35, the 30hp, four-cylinder B-250 was small, nimble and lightweight, but its specification included live hydraulics, inboard disc brakes, diff lock and pickup hitch. In 1958, the B-250 was joined by the B-275, which produced an additional 5hp from a tweaked version of the same BD-144 engine and offered three more forward gears, courtesy of a four forward/one reverse gearbox with a high/low range.

Production of the B-450, a very different beast to the other tractors, also began in 1958. It was a restyle of the BWD 6, but despite its elderly design and technology the 55hp tractor remained in production until 1970.

By the early 1960s, IH was refreshing its UK-built product line and boosting its higher horsepower offering. With the introduction of the B-414 in 1961 came new hood styling and a change from red wheels to white. Production began at Bradford before later moving to Doncaster.

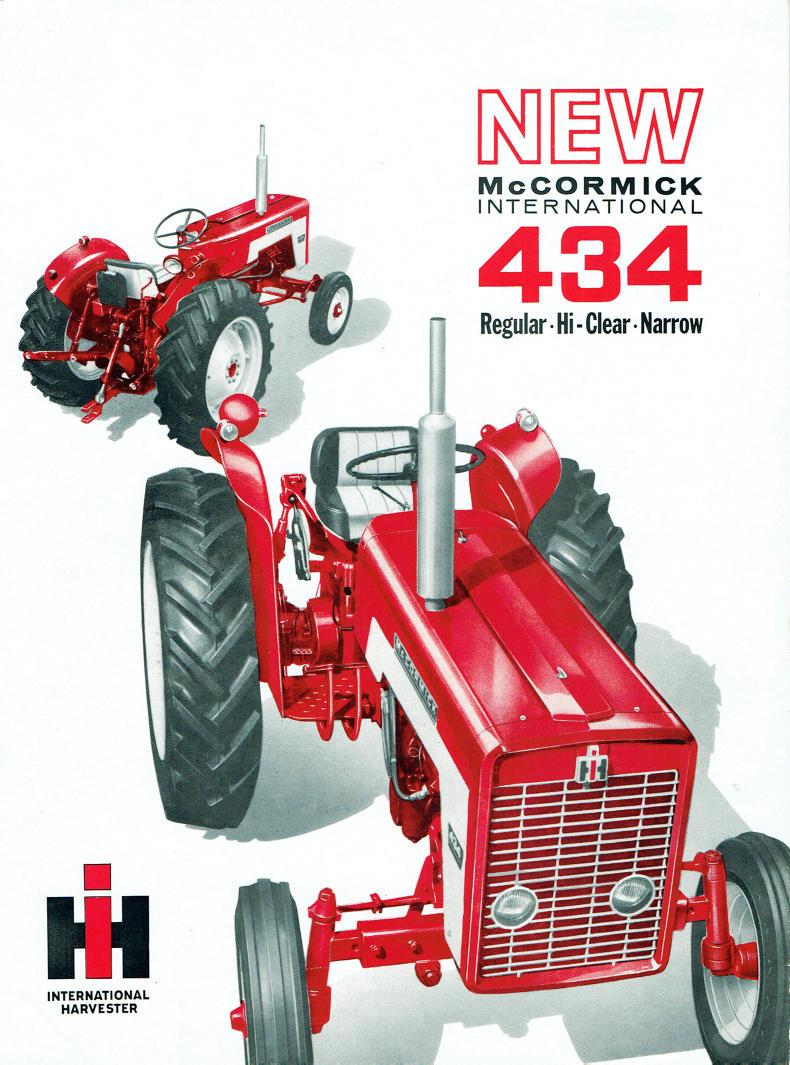

The 40hp B-414 was a replacement for the B-275 and B-276 – although the latter remained in production – and targeted Ford’s 3000 and Massey Ferguson’s 135. Both the B-414 and B-614 that later joined it featured Vary-Touch automatic draft control, a fully live system that allowed the tractor’s hydraulic system to operate independently of the engine drivetrain. The B-414 was replaced by the 434 in 1966.

The 40hp B-414 was a replacement for the B-275 and B-276 – although the latter remained in production – and targeted Ford’s 3000 and Massey Ferguson’s 135. Both the B-414 and B-614 that later joined it featured Vary-Touch automatic draft control, a fully live system that allowed the tractor’s hydraulic system to operate independently of the engine drivetrain. The B-414 was replaced by the 434 in 1966.

In 1964, the B-614 replaced the long-serving B-450. It was the largest UK-produced tractor to be made by IH, delivering 66hp from its long-stroke BD-281 diesel engine, but its relatively heavy build meant it was slightly underpowered. Its specification was also heavy, though, with live hydraulics and exchangeable 540/1,000rpm shafts for the independent power take-off.

The B-276, a refreshed and restyled machine with white and darker red tinwork, succeeded the B-275 in 1968, and was produced until 1974. Repositioned controls and a better seat improved operator comfort, with servicing made easier via a front-mounted air cleaner and removable radiator grille.

Worldwide series

The McCormick name was retired and International was the brand that adorned the flanks of IH tractors when the new Worldwide Series was launched in 1970. While the three smallest machines were manufactured at Bradford, the others were made at Doncaster’s Carr Hill factory. The main Doncaster plant at Wheatley Hall Road focused on manufacturing components and construction equipment. Later, these latter two factory roles were reversed.

The first true Worldwide tractors were the 52hp 454 and 68hp 574, later joined by the similarly-styled 354, 374, 444, 454, 474, 475, 574 and 78hp 674, featuring engines from IH’s Neuss factory in Germany. The exception was the 475, with its UK-sourced Perkins.

The first true Worldwide tractors were the 52hp 454 and 68hp 574, later joined by the similarly-styled 354, 374, 444, 454, 474, 475, 574 and 78hp 674, featuring engines from IH’s Neuss factory in Germany. The exception was the 475, with its UK-sourced Perkins.

A key new feature was a four-speed, two-range synchromesh transmission with a straight-through shift pattern and side console-integrated transmission levers. An optional Torque Amplifier split each gear, reducing engine speed under load by 17%.

IH also introduced a hydrostatic drive option for the 454, 474 and 574. Offering infinitely adjustable travel up to 20mph, the lever-controlled transmission was supplemented by a low range which boosted torque for heavier work. IH also introduced a new safety cab for the range, with full glazing and sound-deadening.

The last major launches from Doncaster under International Harvester ownership were those of the 84 series in 1977, followed by the revised 85 series that succeeded it in 1981. The 84 series initially comprised five models, from the 52hp 484 to the 78hp 784, plus the 82hp Hydro 84. A standard synchromesh version of the latter tractor, the 884, was launched in 1978.

Essentially, a development – but a comprehensive one – of the Worldwide Series tractors, the new 84 models were all four-cylinder tractors, except for the 484, which used IH’s D179 three-cylinder diesel. Later, a 45hp three-cylinder 384 was introduced.

A styling revamp brought new decals, a red, white and black colour scheme and new grille design, while options included four-wheel drive on larger models. Early tractors had the same in-line transmission as the 74 series, while later models featured a new car-like H-pattern gearbox. Torque Amplifer was standard on the 884 and optional on other tractors.

The refreshed 85 series was launched in 1981, a key upgrade being the optional luxury XL cab for the larger models. Just three years later, with Bradford having been closed in 1982 and Carr Hill mothballed, International Harvester, which had been hit globally by a depressed agricultural economy coupled with poor management decisions, decided to sell its farm equipment division. Following the sale of other businesses such as its construction machinery arm and garden equipment division, this left the firm to reinvent itself as Navistar International, a truck, bus and diesel engine maker primarily focused on North America.

Tenneco began merging its JI Case division with International Harvester’s farm equipment operations in early 1985, choosing to preserve IH’s sub-100hp tractors as the basis for its blended Case International tractor range, with a new darker red and black colour scheme replacing IH’s cherry red and white. The 785 and Hydro 85 were dropped, although the former later reappeared. A key improvement was a new four-wheel drive configuration with a centre-line shaft design.

Launched in 1991, the 95 Series introduced a new top model, the turbocharged 90hp 995. Along with a new hood design that featured improved lights and new decals, there was a revised dash, which on XL-cabbed models used digital displays.

In 1996, the tractors were rebadged as Case IH rather than Case International with Navistar, which retained rights to the International brand, having allowed it to be used on the tractors for a 10-year period. New numbering saw the three-cylinder tractors become the 3220 and 3230, and the four-cylinder models the 4210, 4230 and 4240. The long-serving 84/85/95/3200/4200 tractors finally made way in 1997 for a completely new line of CX50-100 models. Combining 3200/4200 rear ends with new Perkins-made engines, all other aspects of the CX were brand new, with features including a synchronised shuttle and new cab.

In short, it was a clean sheet design, but the last that would bear an IH badge as part of its decals. In 2000, the Doncaster plant and product lines plus the McCormick name – Cyrus McCormick’s firm had been a key constituent of International Harvester when it was formed in a series of 1902 mergers – were sold to ARGO, forced by market competition rulings following the proposed takeover of Case Corporation by Fiat, which already owned New Holland.

After a short changeover period, the last tractors bearing an IH badge – albeit alongside a Case one – left the Wheatley Hall Road plant. Carr Hill, by now a components facility, was also sold, to an Italian transmission company. In late 2007, ARGO closed the Doncaster facility and moved McCormick tractor production to its Landini factory in Italy.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: