Situated in Donard, Co Wicklow, Marcus Fenton runs an agri-contracting business alongside a sheep and suckler farming enterprise with his father, Charles.

Last year, a Strautmann Magnon CFS 430 joined Fenton’s extensive fleet of forage wagons, the first of the German manufacturer’s latest generation flagship machines to be sold in Ireland.

Marcus began his career as an agricultural contractor 28 years ago at the age of 16 having bought a Ford 7810 and 8ft-mounted mower, mowing for local contractors.

The Magnon CFS 430 is the smallest of the three models offered within the 40m3 to 52m3 Magnon 10 range.

As the years passed, helped by his dad, he continually reinvested in the business in order to grow it to the stage it’s at today.

Today, Fenton Agri Ltd offers a full range of services to its customers, the majority of whom lie within a 30-mile radius. Pit silage and slurry account for the majority of the annual workload.

In 2021 the Fentons took delivery of a Magnon CFS 430 which they were impressed by.

One Giga-Vitesse CFS 4001, three Tera-Vitesse CFS 4201s and a Magnon 430 currently makes up the Fenton fleet of forage wagons.

Aside from these, baling, muck spreading, fertiliser/ lime spreading and reseeding account for the main services provided.

Thirteen years ago, Marcus bought his first Strautmann Giga-Vitesse II Duo Plus based on quality and the service provided by Gordon Hegarty & Sons, his local dealer.

Marcus believes that the plastic tines will in time become an industry standard on all machines.

Unsure of workload and, to his surprise, he lifted 600 acres during the first year out.

From here, pit silage grew year on year, and so did the fleet of machinery which now comprises five forage wagons.

Every second year, a new wagon was added to the fleet and still is, but now the oldest machine tends to be traded.

The tried-and-tested CFS helps accelerate and evenly disperse crop across the intake channel.

Now that the pickup is hydraulically driven, its speed can be adjusted in accordance to the crop or forward speed.

The Exact-Cut pickup is fitted with 48 reversible knives.

The current fleet consists of one Giga-Vitesse CFS 4001, three Tera-Vitesse CFS 4201’s and a Magnon 430.

Why forage wagons?

Providing almost all other services, silage was the natural progression, he said. “I already had the mowers, rakes and two loaders, a Volvo L70D and a TM320S. Starting out, a forage wagon proved the safest bet, required less labour and a lower overall investment,” Marcus explained.

Today, he feels that forage wagons suit his business now more than ever.

Each of the 48 knives feature an auto break back and reset function.

“The primary reason for running five forage wagons is because of the options it provides me. If the pressure is on, all wagons can be sent out and to three or four farmers if needs be. On the other hand, if the rush is over, fewer can be sent out.”

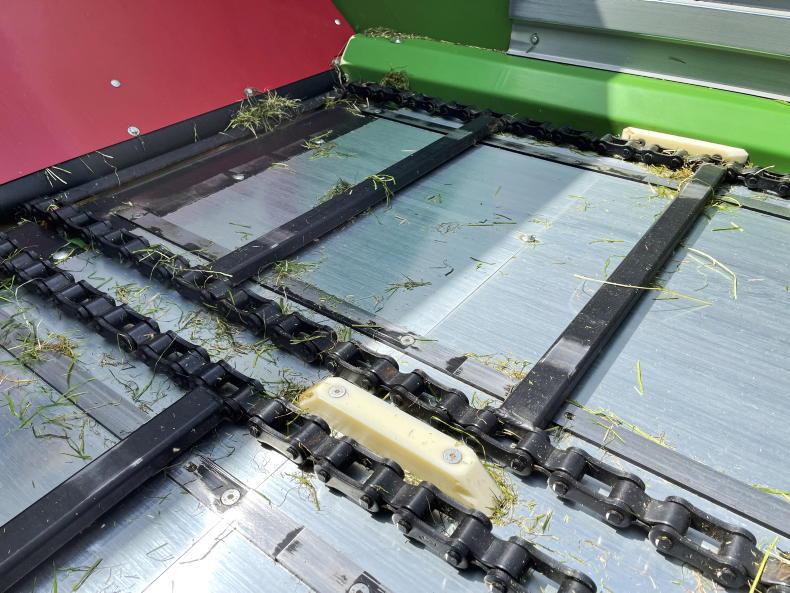

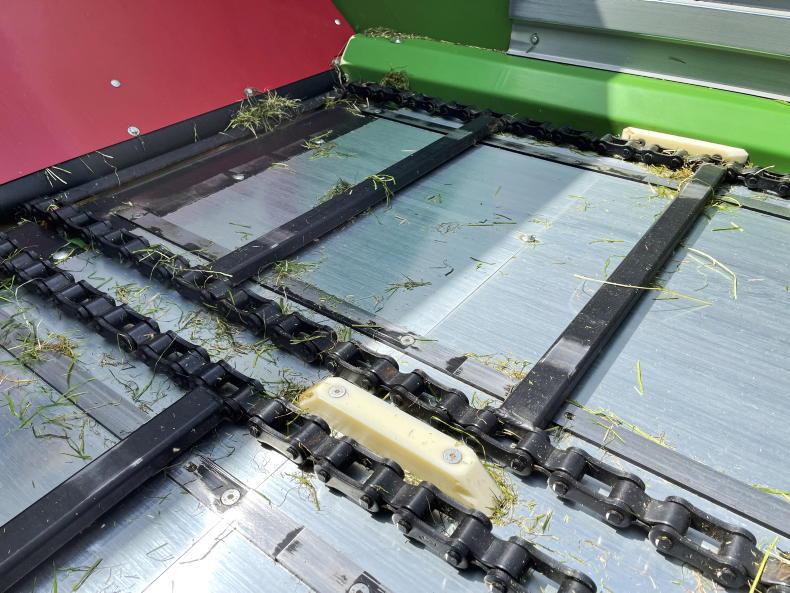

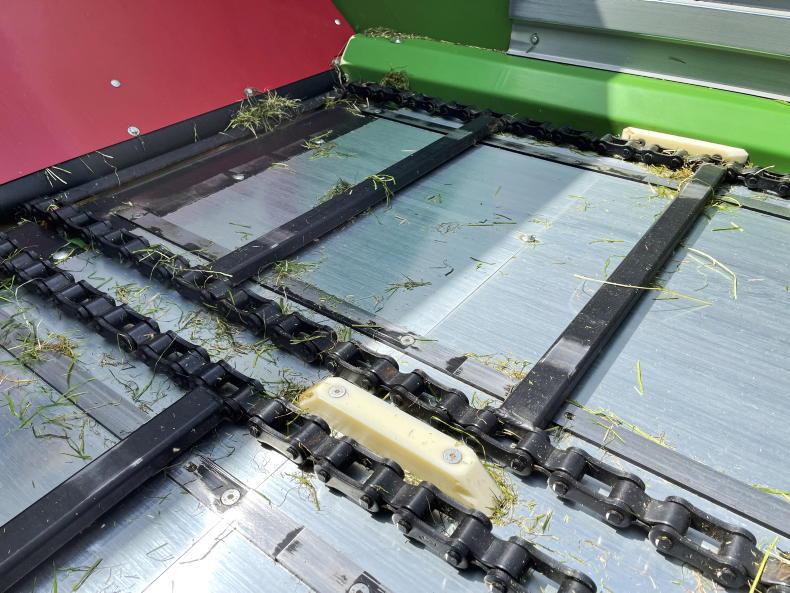

The floor of the Magnon range is constructed from galvanise sheet steel.

The oldest wagon, according to Marcus, tends only to be out for the busiest week in the year and acts as a spare machine the remainder of the time.

The Magnon is unloaded via two hydraulic motors as opposed to one gearbox on the older Teras.

“Given the way it’s worked out, a number of customers would have cut their own silage in years gone by and therefore still have some involvement whether its mowing, raking or pushing up their own grass.

“For example, if it’s the latter, we can just send one wagon which suits both ourselves and the farmer.

“Annual maintenance costs are a fraction of those associated with a forager. I’d safely say that the five wagons combined are lower than one self-propelled.

“On average, each wagon is costing €1,000 in wear parts annually, some years more, some less, but it roughly averages out to this. It takes a lot of money to establish a fleet of fresh wagons but once established, running costs are low.

“What’s more, farmers are now taking on more and more rented land that they often aren’t fully familiar with. As a result, foreign objects have become more common within swards. Obviously, a forage wagon will be more forgiving in the event that such an object is lifted or encountered.”

The moving headboard, plastic tines and auto reset knives are Marcus's major likes of the Magnon.

When it came to upgrading the older Giga-Vitesse models in the fleet, Marcus had been transitioning towards the larger Tera-Vitesse CFS 4201 models. However, in 2019 Strautmann introduced its Magnon range to replace Tera models.

The tractor fleet comprises three John Deere 6215Rs, four 6155Rs, one 7920 and a Massey Ferguson 4270.

The arrival of the Magnon brought with it a number of updates and new styling which had largely gone unchanged since the 1980s.

Marcus got the opportunity to demo the Magnon CFS 430 in 2021.

Marcus runs two Volvo L70 loading shovels in the fleet with the option of running two JCB TM320S pivot steers when required.

Impressed with its performance, a deal was struck ahead of the 2022 season to buy a CFS 430, the smallest model within the Magnon 10 range.

One of the major Magnon updates is its pickup. It is equipped with a 2.25m camless reel which sees six rows of flexible plastic tines, configured in a chevron pattern as before.

These chunky looking 10mm-wide plastic tines have impressed Marcus, who notes that they “lick the grass off the ground” and prove much more efficient at collecting shorter grass, he said.

The Magnon range is fitted with active rear axle steering as standard.

“After 700 acres, not one has broken or shown any signs of wear which says enough. They’ll sooner perish than break.”

Contamination has reduced too as the plastic tine can deflect from surface contact better than conventional steel tines, which build pressure as the level of contact increases.

The pickup is now hydraulically driven instead of chain-driven, a feature Marcus likes as it reduces maintenance and allows the option of adjusting its speed independently on the move, either manually or in accordance with the tractor’s forward speed via a wheel speed sensor.

Pickup rotation stops once it’s lifted to reduce wear. This, and the quieter overall running of the pickup due to its plastic tines and hydraulic drive, are two aspects Marcus praises.

Marcus believes that the plastic tines will in time become an industry standard on all machines.

Rotor

The tried-and-tested continuous flow system (CFS) remains an integral feature of the Magnon. Positioned between the pickup reel and rotor, the CFS is there to both accelerate and disperse crop across the entire width of the pickup, similar to how a combine header auger works but in reverse.

One feature Marcus did note that the Magnon potentially lacked and is offered by most competitors now is a sloped floor behind the rotor which many claim reduces the power requirement. However, contrary to this, Strautmann claim from its in-house testing that the sloped concept actually increased power requirement. It believes that CFS helps maintain a higher rotor position and thus helps reduce the power requirement.

The rotor is 2.1m-wide (1.74m feed width) and 840mm in diameter with eight rows of 17mm-wide tines in a helical configuration. To the left and right and side of the rotor are 17.5cm augers to help direct the crop into the feed area. The rotor drive is kept simple via planetary gearbox.

The tried-and-tested CFS helps accelerate and evenly disperse crop across the intake channel.

New on last Tera models and officially on the Magnon is the Exact-Cut knife bank which Marcus considers another big step forward.

It sees 48 double-sided knives as opposed to 50 on the older Tera models.

Theoretical chop length is 35mm but the major difference is that every knife is now individually protected and automatically reset as opposed to manually. Tripping force is adjustable.

The Exact-Cut pickup is fitted with 48 reversible knives.

While swing out pickups are nice features for maintenance, it is not something done by Strautmann. It claims that wear/pivot points need to be minimised in order to achieve a precise chop and so they avoided the feature.

This is a point Marcus considers logical and believes should stand to his machines in seasons to come.

He believes knives are still quite easily accessed for maintenance once lowered and the front end raised on the drawbar.

Marcus is a strong believer that sharp knives are key and lead to reduced fuel consumption, reduced pickup wear and a reduction in workload back at the pit as the grass is easier handled.

Typically, knives on all Fenton’s machines are sharpened or reversed every second day during first cut, a total nearing 600 knives including the three balers.

Marcus has a policy that if a wagon is going to be parked for more than two days then knife banks need to be cleaned and oiled.

“The most effective way is to run straw through the pickup to remove any grass residue before washing and oiling. The slightly acidic nature of grass means it’s critical for performance and longevity that the pickup and knife bank is properly maintained after use,” he explained.

Another major feature welcomed with the arrival of the Magnon is the moving headboard.

Not only does it leave the wagon more compact as the pickup is now under the body, but it helps compression while loading and speeds up unloading.

Once the headboard is pivoted back while nearing full, a further 5m3 of space is created. This has allowed Magnon capacities to be increased while length has been decreased in comparison to the equivalent Tera models.

The floor in all Magnons is galvanised steel as opposed to timber. The previous central gearbox driving the floor chains has been replaced with twin hydraulic motors.

Marcus runs a fleet of well specified R series John Deeres equipped with Isobus and guidance so he opted to go full Isobus and ditch the option of a standalone control terminal. So far, he has no regrets and likes the layout of the Strautmann run screens. There are dedicated run screens for transport, loading and unloading with buttons for the associated mode only accessible. The automatic function works well, he said.

As standard, the Magnon comes fitted with hydraulic axle suspension and forced steering, the latter which Marcus has fitted to the majority of machinery within the fleet.

The moving headboard, plastic tines and auto reset knives are Marcus's major likes of the Magnon.

After 13 years of Strautmann forage wagons, the Fentons continue to be satisfied with reliability and performance.

“Aside from a few minor issues and a gearbox replacement under warranty, all Strautmann wagons have served us well so far. I’d be a believer that maintenance is the secret. For example, washing down the pickup, oiling it and keeping all points greased frequently.

“The Magnon was a welcome step forward in the areas it intended to be. By this, I mean features such as the pickup tines, auto reset knives, headboard and Isobus control, etc. The plastic tines in particular are something I can see become an industry standard eventually.

“We used to carry out a few reinforcement modification on Giga and Tera models for precaution but, to be fair, the Magnon hasn’t needed reinforcing. Another add-on we would have done to all Giga and Tera models was the fitting of a top canopy to hold in and help pack grass. However, the moving headboard has left it not so simple on the Magnon but we could find a way around it yet,” Marcus laughed.

Model: Magnon CFS 430.Capacity: 42m3.Pickup: 2.25m camless, hydraulic drive.Knives: 48 double-sided with auto breakback and reset.Chop length: 35mm theoretical.Unladen weight: 11.1t.List price: €228,430 plus VAT.

Situated in Donard, Co Wicklow, Marcus Fenton runs an agri-contracting business alongside a sheep and suckler farming enterprise with his father, Charles.

Last year, a Strautmann Magnon CFS 430 joined Fenton’s extensive fleet of forage wagons, the first of the German manufacturer’s latest generation flagship machines to be sold in Ireland.

Marcus began his career as an agricultural contractor 28 years ago at the age of 16 having bought a Ford 7810 and 8ft-mounted mower, mowing for local contractors.

The Magnon CFS 430 is the smallest of the three models offered within the 40m3 to 52m3 Magnon 10 range.

As the years passed, helped by his dad, he continually reinvested in the business in order to grow it to the stage it’s at today.

Today, Fenton Agri Ltd offers a full range of services to its customers, the majority of whom lie within a 30-mile radius. Pit silage and slurry account for the majority of the annual workload.

In 2021 the Fentons took delivery of a Magnon CFS 430 which they were impressed by.

One Giga-Vitesse CFS 4001, three Tera-Vitesse CFS 4201s and a Magnon 430 currently makes up the Fenton fleet of forage wagons.

Aside from these, baling, muck spreading, fertiliser/ lime spreading and reseeding account for the main services provided.

Thirteen years ago, Marcus bought his first Strautmann Giga-Vitesse II Duo Plus based on quality and the service provided by Gordon Hegarty & Sons, his local dealer.

Marcus believes that the plastic tines will in time become an industry standard on all machines.

Unsure of workload and, to his surprise, he lifted 600 acres during the first year out.

From here, pit silage grew year on year, and so did the fleet of machinery which now comprises five forage wagons.

Every second year, a new wagon was added to the fleet and still is, but now the oldest machine tends to be traded.

The tried-and-tested CFS helps accelerate and evenly disperse crop across the intake channel.

Now that the pickup is hydraulically driven, its speed can be adjusted in accordance to the crop or forward speed.

The Exact-Cut pickup is fitted with 48 reversible knives.

The current fleet consists of one Giga-Vitesse CFS 4001, three Tera-Vitesse CFS 4201’s and a Magnon 430.

Why forage wagons?

Providing almost all other services, silage was the natural progression, he said. “I already had the mowers, rakes and two loaders, a Volvo L70D and a TM320S. Starting out, a forage wagon proved the safest bet, required less labour and a lower overall investment,” Marcus explained.

Today, he feels that forage wagons suit his business now more than ever.

Each of the 48 knives feature an auto break back and reset function.

“The primary reason for running five forage wagons is because of the options it provides me. If the pressure is on, all wagons can be sent out and to three or four farmers if needs be. On the other hand, if the rush is over, fewer can be sent out.”

The floor of the Magnon range is constructed from galvanise sheet steel.

The oldest wagon, according to Marcus, tends only to be out for the busiest week in the year and acts as a spare machine the remainder of the time.

The Magnon is unloaded via two hydraulic motors as opposed to one gearbox on the older Teras.

“Given the way it’s worked out, a number of customers would have cut their own silage in years gone by and therefore still have some involvement whether its mowing, raking or pushing up their own grass.

“For example, if it’s the latter, we can just send one wagon which suits both ourselves and the farmer.

“Annual maintenance costs are a fraction of those associated with a forager. I’d safely say that the five wagons combined are lower than one self-propelled.

“On average, each wagon is costing €1,000 in wear parts annually, some years more, some less, but it roughly averages out to this. It takes a lot of money to establish a fleet of fresh wagons but once established, running costs are low.

“What’s more, farmers are now taking on more and more rented land that they often aren’t fully familiar with. As a result, foreign objects have become more common within swards. Obviously, a forage wagon will be more forgiving in the event that such an object is lifted or encountered.”

The moving headboard, plastic tines and auto reset knives are Marcus's major likes of the Magnon.

When it came to upgrading the older Giga-Vitesse models in the fleet, Marcus had been transitioning towards the larger Tera-Vitesse CFS 4201 models. However, in 2019 Strautmann introduced its Magnon range to replace Tera models.

The tractor fleet comprises three John Deere 6215Rs, four 6155Rs, one 7920 and a Massey Ferguson 4270.

The arrival of the Magnon brought with it a number of updates and new styling which had largely gone unchanged since the 1980s.

Marcus got the opportunity to demo the Magnon CFS 430 in 2021.

Marcus runs two Volvo L70 loading shovels in the fleet with the option of running two JCB TM320S pivot steers when required.

Impressed with its performance, a deal was struck ahead of the 2022 season to buy a CFS 430, the smallest model within the Magnon 10 range.

One of the major Magnon updates is its pickup. It is equipped with a 2.25m camless reel which sees six rows of flexible plastic tines, configured in a chevron pattern as before.

These chunky looking 10mm-wide plastic tines have impressed Marcus, who notes that they “lick the grass off the ground” and prove much more efficient at collecting shorter grass, he said.

The Magnon range is fitted with active rear axle steering as standard.

“After 700 acres, not one has broken or shown any signs of wear which says enough. They’ll sooner perish than break.”

Contamination has reduced too as the plastic tine can deflect from surface contact better than conventional steel tines, which build pressure as the level of contact increases.

The pickup is now hydraulically driven instead of chain-driven, a feature Marcus likes as it reduces maintenance and allows the option of adjusting its speed independently on the move, either manually or in accordance with the tractor’s forward speed via a wheel speed sensor.

Pickup rotation stops once it’s lifted to reduce wear. This, and the quieter overall running of the pickup due to its plastic tines and hydraulic drive, are two aspects Marcus praises.

Marcus believes that the plastic tines will in time become an industry standard on all machines.

Rotor

The tried-and-tested continuous flow system (CFS) remains an integral feature of the Magnon. Positioned between the pickup reel and rotor, the CFS is there to both accelerate and disperse crop across the entire width of the pickup, similar to how a combine header auger works but in reverse.

One feature Marcus did note that the Magnon potentially lacked and is offered by most competitors now is a sloped floor behind the rotor which many claim reduces the power requirement. However, contrary to this, Strautmann claim from its in-house testing that the sloped concept actually increased power requirement. It believes that CFS helps maintain a higher rotor position and thus helps reduce the power requirement.

The rotor is 2.1m-wide (1.74m feed width) and 840mm in diameter with eight rows of 17mm-wide tines in a helical configuration. To the left and right and side of the rotor are 17.5cm augers to help direct the crop into the feed area. The rotor drive is kept simple via planetary gearbox.

The tried-and-tested CFS helps accelerate and evenly disperse crop across the intake channel.

New on last Tera models and officially on the Magnon is the Exact-Cut knife bank which Marcus considers another big step forward.

It sees 48 double-sided knives as opposed to 50 on the older Tera models.

Theoretical chop length is 35mm but the major difference is that every knife is now individually protected and automatically reset as opposed to manually. Tripping force is adjustable.

The Exact-Cut pickup is fitted with 48 reversible knives.

While swing out pickups are nice features for maintenance, it is not something done by Strautmann. It claims that wear/pivot points need to be minimised in order to achieve a precise chop and so they avoided the feature.

This is a point Marcus considers logical and believes should stand to his machines in seasons to come.

He believes knives are still quite easily accessed for maintenance once lowered and the front end raised on the drawbar.

Marcus is a strong believer that sharp knives are key and lead to reduced fuel consumption, reduced pickup wear and a reduction in workload back at the pit as the grass is easier handled.

Typically, knives on all Fenton’s machines are sharpened or reversed every second day during first cut, a total nearing 600 knives including the three balers.

Marcus has a policy that if a wagon is going to be parked for more than two days then knife banks need to be cleaned and oiled.

“The most effective way is to run straw through the pickup to remove any grass residue before washing and oiling. The slightly acidic nature of grass means it’s critical for performance and longevity that the pickup and knife bank is properly maintained after use,” he explained.

Another major feature welcomed with the arrival of the Magnon is the moving headboard.

Not only does it leave the wagon more compact as the pickup is now under the body, but it helps compression while loading and speeds up unloading.

Once the headboard is pivoted back while nearing full, a further 5m3 of space is created. This has allowed Magnon capacities to be increased while length has been decreased in comparison to the equivalent Tera models.

The floor in all Magnons is galvanised steel as opposed to timber. The previous central gearbox driving the floor chains has been replaced with twin hydraulic motors.

Marcus runs a fleet of well specified R series John Deeres equipped with Isobus and guidance so he opted to go full Isobus and ditch the option of a standalone control terminal. So far, he has no regrets and likes the layout of the Strautmann run screens. There are dedicated run screens for transport, loading and unloading with buttons for the associated mode only accessible. The automatic function works well, he said.

As standard, the Magnon comes fitted with hydraulic axle suspension and forced steering, the latter which Marcus has fitted to the majority of machinery within the fleet.

The moving headboard, plastic tines and auto reset knives are Marcus's major likes of the Magnon.

After 13 years of Strautmann forage wagons, the Fentons continue to be satisfied with reliability and performance.

“Aside from a few minor issues and a gearbox replacement under warranty, all Strautmann wagons have served us well so far. I’d be a believer that maintenance is the secret. For example, washing down the pickup, oiling it and keeping all points greased frequently.

“The Magnon was a welcome step forward in the areas it intended to be. By this, I mean features such as the pickup tines, auto reset knives, headboard and Isobus control, etc. The plastic tines in particular are something I can see become an industry standard eventually.

“We used to carry out a few reinforcement modification on Giga and Tera models for precaution but, to be fair, the Magnon hasn’t needed reinforcing. Another add-on we would have done to all Giga and Tera models was the fitting of a top canopy to hold in and help pack grass. However, the moving headboard has left it not so simple on the Magnon but we could find a way around it yet,” Marcus laughed.

Model: Magnon CFS 430.Capacity: 42m3.Pickup: 2.25m camless, hydraulic drive.Knives: 48 double-sided with auto breakback and reset.Chop length: 35mm theoretical.Unladen weight: 11.1t.List price: €228,430 plus VAT.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: