The beef forum or roundtable as it was originally known held a low-key meeting this week.

It is now three years since the group was established and one of the agreed objectives – of getting continual supervision of carcase trimming installed in meat factories – still hasn’t been delivered.

In the era before machines performed the grading function, Department staff provided the grading service and in the process monitored the trimming of carcases to make sure carcases were trimmed precisely to the correct specification.

The Livestock and Meat Commission (LMC) performed the service in Northern Ireland.

Mechanical grading

Mechanical grading of cattle was introduced in the Republic of Ireland in 2004 and in 2011 in Northern Ireland which means that there are no independent eyes scrutinising how cattle are trimmed or if in fact the machine is providing a satisfactory service.

When machines aren’t working, factory staff provide a manual classification service as a backup.

With no independent staff present on an ongoing basis, the only scrutiny that takes place of how well factories are doing their job is the regular audits carried out by licensed classification staff in the respective Government departments.

In the Republic of Ireland, 57,256 cattle were checked by DAFM staff in 2016, during 516 factory visits and a similar scrutiny process is carried out in Northern Ireland, with one important difference.

Inspection report

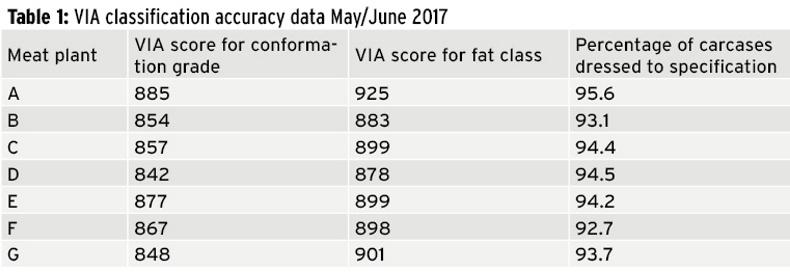

In the north, a report of inspections is published on the internet every two months (Figure 1) scoring on the accuracy of the machine measuring the confirmation on the EUROP grid, fat cover and the percentage of carcases trimmed as they should be.

This is done on an anonymous basis, so while we can see if a factory or factories are better or worse than others, we cannot identify which factory it is.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: