There were a number of stops at the AHDB Beef Science Live event held at Harper Adams University last week, each focusing on a different aspect of profitable beef production. Here we present the take home messages from each one.

Improving liver fluke control in cattle

– Diana Williams

A thought-provoking presentation. The speaker said that the biggest mud snail (intermediate hosts for fluke) populations in fields are found in depressions or previously damaged areas.

However, snail populations are low in recently poached fields and in shaded areas.

Farmers were advised not to rely on faecal egg sample for diagnosing liver fluke – they are only effective 10 weeks after infection.

The mud snails that act as hosts for liver fluke (pictured) are not much bigger than a peppercorn

Driving improvement using key performance indicators – Neil Rowe

Neil showed how the pursuit of the perfect cow was paying dividends for farmers. He outlined some rules and KPIs that he uses on his own and other herds.

Cow mature weight no heavier than target progeny slaughter weight.Calfs weigh 50% of cow mature weight at 200 days – “animals not achieving this won’t make a profit”.After 70 days with the bull 95% should be in calf.Sixty per cent calving in the first 21 days – “animals born in the first 21 days will make profit, the second 21 will break even and the third 21 will lose money”.Ninety per cent of data generated on farm is never used – data needs to be acted upon.“Where you’ve a 750kg cow producing a 340kg calf, 90% of the energy you put into that pair goes towards maintenance and 10% into production. What business can generate a margin from a turnover of 10%?”

Suckler cow nutrition using BCS – Debbie Brown

Debbie’s BCS targets and methods for hitting them mirror ours, but there were a few interesting points.

In individual cases of condition loss, always check feet first even if there is no sign of lameness.Ensure correct stock bull body condition 10-12 weeks before breeding.It is much more economical to wean first-calvers early and creep feed calves than to have them lose condition late in the season and to build it back up pre-calving.Optimising cow BCS leads to better immunity in calves (higher colostrum immunoglobulin concentration).Profitable beef from dairy production systems – Rob Prendiville

Teagasc’s Rob Prendiville outlined his latest dairy beef research findings, showing that net margin per head was highest in three-season systems (28 month Friesian/26 month AA/HE).

Rob’s budgets assumed €100 for a Friesian bull and €240 and €270 for AA/HE-cross heifers and bulls respectively. A base beef price of €4.00 was also factored in. Net margins were both in excess of €300.

Such systems sell animals at a typically good time price-wise and represent an easier means to get cattle out early in the spring when compared with suckling.

Early turnout to quality spring grass leads to

lucrative weight

gain.

Getting better performance from cattle at grass – Marc Jones

It was a case of starting from scratch at the grassland stop, an area which in truth warrants its own full day. Data was presented from the Teagasc BEEF 2016 event and preliminary findings from some set-stocked versus rotational grazing work being done locally on farms.

Marc stressed the importance of focusing on grass going forward, given its cost relative to conserved forage and grain and uncertainty around subsidies.

AHDB and beef at Harper Adams University

The Agriculture and Horticulture Development Board (AHDB) is a statutory levy board, funded by farmers, growers and others in the supply chain and managed as an independent organisation (independent of both commercial industry and of government).

Their purpose is to “inspire our farmers, growers and industry to succeed in a rapidly changing world”.

University

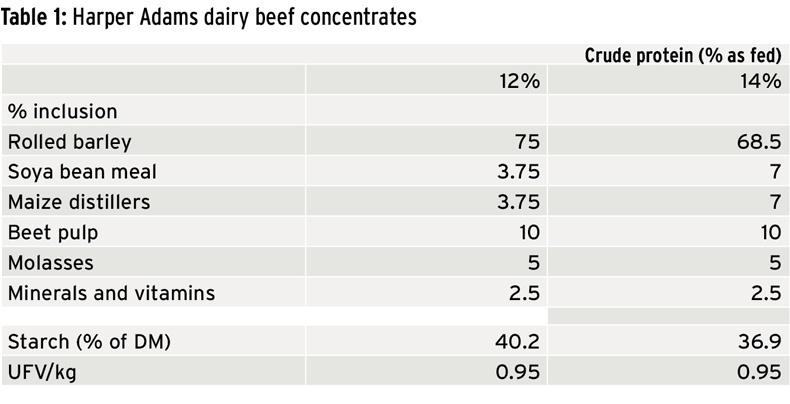

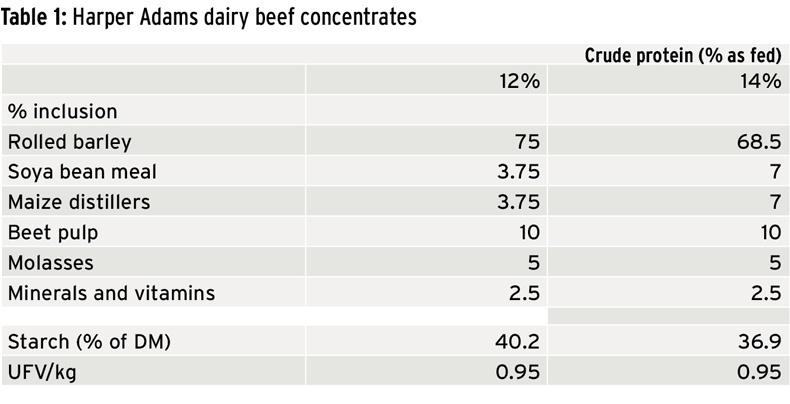

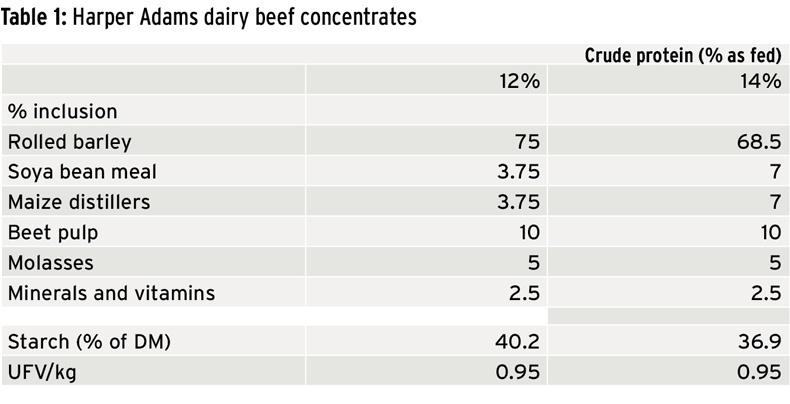

Harper Adams university is today home to over 2,000 students. Its beef unit finishes dairy-bred bulls from the university’s 400 head dairy herd, the majority of which are produced in a cereal beef system at 13-15 months.

The calves enter the cereal beef unit at 12 weeks and move onto a 14% crude protein ration fed ad lib. At 275kg, this is dropped to a 12%.

At 14 months, Holstein and continental x Holstein bulls achieve carcase weights of 285kg and 335kg respectively. This equates to slaughter weights of 570kg and 600kg.

With beef prices of £3.05 (HO) and £3.30 (cont. x HO), gross margin per head is £331 and £354 respectively.

Current trial work

Comparison of bulls versus steers.Replacement of barley with wheat in bull-finishing diets.Differing ration crude protein levels in maize silage-based heifer diets.Production of Holstein Friesian steers in 20-month, outdoor forage systems.Effect of differing levels of milk replacer on 12-week performance of rearing calves.Evaluation of milk feeding patterns on performance of rearing calves.In some respects, you might as well be in North America as England when comparing beef production systems to ours – the contrasts are stark. Again, it all comes back to farm size.

The typical farm in this region of England spans hundreds of acres and will support a family on its subsidies alone. Like Ireland, the gulf between the top and inferior operations in terms of efficiency and profitability are stark – a function of CAP payments perhaps.

However, big, efficient suckler farms in the region have bought into the North American philosophy of a handy, hardy cow who’ll do the majority of the work herself. Many of these farmers are running traditional-breed herds, with some having gone down the stabiliser route, aiming for bigger carcase weights.

For me, their best suckler operators are right up there with ours on individual animal basis. Take Neil Rowe for example.

Cows really must earn their keep in his herd, with fertility and calf weaning weight crucial. Indeed, some of his lofty suckler KPIs seemed outlandish, but obviously achievable.

The almost pedantic push for weaning weight and fertility is akin to what you have in North America and driven by a need for a cow model that can be worked in big numbers by very few labour units.

But are these numbers enough?

Stocking rates on suckler farms in the region are generally low, even on efficient holdings. Grass is often a break crop in a tillage rotation. Now, with Brexit and the threat to CAP payments, farmers are looking at output to fill the potential future holes in their income. That output will come via higher stocking rates which will require a focus on grassland.

Yet, as it stands, intensive grass-based beef systems are few and far between in the region.

All of the data used on the potential of grass at the Beef Science Live event was from work done by Teagasc.

Current AHDB research into beef grazing systems is simply just comparing output from set-stocked versus rotationally grazed land and is farm-based.

Grassland

In terms of adopting intensive approaches to grassland, they are well behind what’s being done here in Ireland.

However, given the capital required to establish sufficient grazing infrastructure on farms of this scale and the fact that boosting stocking rates to match grass growth in rotational grazing systems will potentially put a huge drain on cash and labour via extra cattle, this is understandable. Going forward, we in Ireland can definitely learn from the standards set for the optimum English suckler cow.

On the grass end, there is little to take home that hasn’t already been drilled in here.

In fact, the UK will continue to look here for guidance as intensive grazing momentum gathers there.

There were a number of stops at the AHDB Beef Science Live event held at Harper Adams University last week, each focusing on a different aspect of profitable beef production. Here we present the take home messages from each one.

Improving liver fluke control in cattle

– Diana Williams

A thought-provoking presentation. The speaker said that the biggest mud snail (intermediate hosts for fluke) populations in fields are found in depressions or previously damaged areas.

However, snail populations are low in recently poached fields and in shaded areas.

Farmers were advised not to rely on faecal egg sample for diagnosing liver fluke – they are only effective 10 weeks after infection.

The mud snails that act as hosts for liver fluke (pictured) are not much bigger than a peppercorn

Driving improvement using key performance indicators – Neil Rowe

Neil showed how the pursuit of the perfect cow was paying dividends for farmers. He outlined some rules and KPIs that he uses on his own and other herds.

Cow mature weight no heavier than target progeny slaughter weight.Calfs weigh 50% of cow mature weight at 200 days – “animals not achieving this won’t make a profit”.After 70 days with the bull 95% should be in calf.Sixty per cent calving in the first 21 days – “animals born in the first 21 days will make profit, the second 21 will break even and the third 21 will lose money”.Ninety per cent of data generated on farm is never used – data needs to be acted upon.“Where you’ve a 750kg cow producing a 340kg calf, 90% of the energy you put into that pair goes towards maintenance and 10% into production. What business can generate a margin from a turnover of 10%?”

Suckler cow nutrition using BCS – Debbie Brown

Debbie’s BCS targets and methods for hitting them mirror ours, but there were a few interesting points.

In individual cases of condition loss, always check feet first even if there is no sign of lameness.Ensure correct stock bull body condition 10-12 weeks before breeding.It is much more economical to wean first-calvers early and creep feed calves than to have them lose condition late in the season and to build it back up pre-calving.Optimising cow BCS leads to better immunity in calves (higher colostrum immunoglobulin concentration).Profitable beef from dairy production systems – Rob Prendiville

Teagasc’s Rob Prendiville outlined his latest dairy beef research findings, showing that net margin per head was highest in three-season systems (28 month Friesian/26 month AA/HE).

Rob’s budgets assumed €100 for a Friesian bull and €240 and €270 for AA/HE-cross heifers and bulls respectively. A base beef price of €4.00 was also factored in. Net margins were both in excess of €300.

Such systems sell animals at a typically good time price-wise and represent an easier means to get cattle out early in the spring when compared with suckling.

Early turnout to quality spring grass leads to

lucrative weight

gain.

Getting better performance from cattle at grass – Marc Jones

It was a case of starting from scratch at the grassland stop, an area which in truth warrants its own full day. Data was presented from the Teagasc BEEF 2016 event and preliminary findings from some set-stocked versus rotational grazing work being done locally on farms.

Marc stressed the importance of focusing on grass going forward, given its cost relative to conserved forage and grain and uncertainty around subsidies.

AHDB and beef at Harper Adams University

The Agriculture and Horticulture Development Board (AHDB) is a statutory levy board, funded by farmers, growers and others in the supply chain and managed as an independent organisation (independent of both commercial industry and of government).

Their purpose is to “inspire our farmers, growers and industry to succeed in a rapidly changing world”.

University

Harper Adams university is today home to over 2,000 students. Its beef unit finishes dairy-bred bulls from the university’s 400 head dairy herd, the majority of which are produced in a cereal beef system at 13-15 months.

The calves enter the cereal beef unit at 12 weeks and move onto a 14% crude protein ration fed ad lib. At 275kg, this is dropped to a 12%.

At 14 months, Holstein and continental x Holstein bulls achieve carcase weights of 285kg and 335kg respectively. This equates to slaughter weights of 570kg and 600kg.

With beef prices of £3.05 (HO) and £3.30 (cont. x HO), gross margin per head is £331 and £354 respectively.

Current trial work

Comparison of bulls versus steers.Replacement of barley with wheat in bull-finishing diets.Differing ration crude protein levels in maize silage-based heifer diets.Production of Holstein Friesian steers in 20-month, outdoor forage systems.Effect of differing levels of milk replacer on 12-week performance of rearing calves.Evaluation of milk feeding patterns on performance of rearing calves.In some respects, you might as well be in North America as England when comparing beef production systems to ours – the contrasts are stark. Again, it all comes back to farm size.

The typical farm in this region of England spans hundreds of acres and will support a family on its subsidies alone. Like Ireland, the gulf between the top and inferior operations in terms of efficiency and profitability are stark – a function of CAP payments perhaps.

However, big, efficient suckler farms in the region have bought into the North American philosophy of a handy, hardy cow who’ll do the majority of the work herself. Many of these farmers are running traditional-breed herds, with some having gone down the stabiliser route, aiming for bigger carcase weights.

For me, their best suckler operators are right up there with ours on individual animal basis. Take Neil Rowe for example.

Cows really must earn their keep in his herd, with fertility and calf weaning weight crucial. Indeed, some of his lofty suckler KPIs seemed outlandish, but obviously achievable.

The almost pedantic push for weaning weight and fertility is akin to what you have in North America and driven by a need for a cow model that can be worked in big numbers by very few labour units.

But are these numbers enough?

Stocking rates on suckler farms in the region are generally low, even on efficient holdings. Grass is often a break crop in a tillage rotation. Now, with Brexit and the threat to CAP payments, farmers are looking at output to fill the potential future holes in their income. That output will come via higher stocking rates which will require a focus on grassland.

Yet, as it stands, intensive grass-based beef systems are few and far between in the region.

All of the data used on the potential of grass at the Beef Science Live event was from work done by Teagasc.

Current AHDB research into beef grazing systems is simply just comparing output from set-stocked versus rotationally grazed land and is farm-based.

Grassland

In terms of adopting intensive approaches to grassland, they are well behind what’s being done here in Ireland.

However, given the capital required to establish sufficient grazing infrastructure on farms of this scale and the fact that boosting stocking rates to match grass growth in rotational grazing systems will potentially put a huge drain on cash and labour via extra cattle, this is understandable. Going forward, we in Ireland can definitely learn from the standards set for the optimum English suckler cow.

On the grass end, there is little to take home that hasn’t already been drilled in here.

In fact, the UK will continue to look here for guidance as intensive grazing momentum gathers there.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: