As all dairy farmers will be aware, they are paid for their milk monthly in arrears. So the milk payments being lodged this week are based on February’s supply. Supply is measured in litres but milk price is based on milk quality.

The biggest quality variable in milk is the fat and protein percentage. Different processors put different values on the fat and protein, depending on how important it is to their product mix and what was done historically. In an A+B-C payment structure, the value of fat and protein minus the water content makes up the entire payment system. Most processors in the Republic of Ireland are using some form of an A+B-C payment system.

In Northern Ireland, the payment system is still based around litres, with a bonus or a deduction based on fat and protein percent above or below 3.6% fat and 3.3% protein.

The other main quality tests both north and south are somatic cell count (SCC), thermoduric and bacteria which is measured either as total bacteria count (TBC) or bactoscan. Failure to meet specific quality parameters for each of these tests will result in deductions or a bonus on the entire milk supply for that month. Most of these quality parameters are applied on a geometric average basis.

So what about the milk testing for solids? Obviously, regular tests are essential to make sure that the farmer is being paid for the exact quality of milk that is delivered. Ideally, every load of milk sent to the milk processor should be sampled for quality.

Some processors are not able to do a fat and protein test and a TBC or a thermoduric test on the same sample so that rules out around three collections per month from a fat and protein test.

For most farmers, fat and protein test results have the biggest effect on their price received per litre. For farmers whose milk is collected every two days, they will have between 14 and 16 milk collections every month. Those on three days collection only have 10 collections per month.

Milk quality payments are based on the average test results for the month. So if only half of their collections are being tested for fat and protein, it means that their average fat and protein for the month is based on only half of their actual supply.

This would be akin to a grain farmer only having every second load of grain tested for moisture and bushel weight but being paid for all grain delivered on the basis of the loads that were tested. So if it happened that the loads tested were all from poor sections of fields or from headlands then the grower would be at a major disadvantage.

The same applies when not every load of milk is tested. We all know that fat and protein rises and falls depending on the cow’s diet. When grass is in the diet protein rises and when low-protein silage is in the diet protein falls.

When not every collection of milk is being tested for fat and protein, then the farmer could be at a significant loss if the milk is tested when cows are on silage and not tested when cows are at grass. The effects of this are most obvious now as cows are moving between grass and silage diets depending on the weather.

Testing while on silage

Farmers who are misfortunate enough to have their milk tested when their cows are in on silage and not tested when their cows are out grazing are effectively supplying high-value milk to the processor for no additional reward.

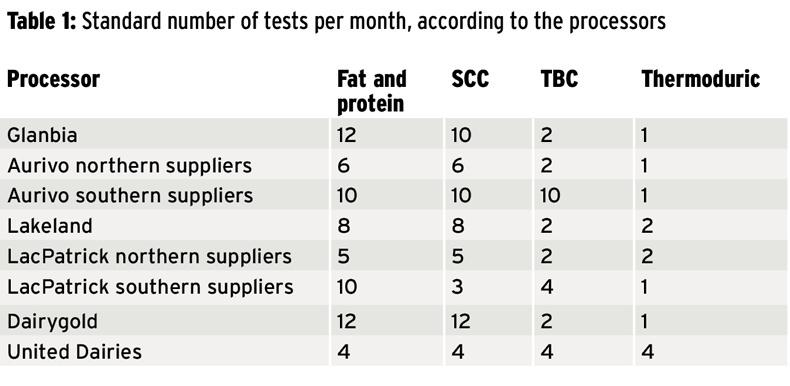

Table 1 details the main milk processors north and south and how often they say they are testing for milk. There is a noticeable difference in the regularity of testing between the processors with bases in the south, and those with bases in Northern Ireland.

I spoke to a Lakeland supplier whose milk has only been tested for fat and protein in eight of the last 24 collections. It is a similar story with United Dairies. One of their supplier’s milk has only been tested in seven of the last 25 collections.

In contrast, a Glanbia supplier I spoke to has been tested for fat and protein in 20 of the last 24 collections. Dairygold suppliers report similar levels of testing. LacPatrick suppliers in the Republic are tested a minimum of 10 times per month, but those in Northern Ireland are on a different payment system and are only tested five times per month.

Suppliers need encouragement and a clear signal from processors that producing more fat and protein will be rewarded and recognised. If product sold to their processor is not being tested regularly they are not getting a fair reflection of the results they deserve. The gold standard and what all processors should be aiming for is that all collections are tested for fat and protein concentration. Suppliers, where less frequent testing is taking place, have less of an incentive to try and increase the quality of feed and hence the quality of product delivered. Yes, there is a cost to the processor but suppliers deserve accurate results.

SHARING OPTIONS