Last week, Teagasc held a walk on the farm of Tommy and TJ Ryan at Rossmore, about 15 miles west of Thurles, Co Tipperary.

The Ryans have increased numbers from 50 to 74 milking cows since 2009 and the plan is to milk 90 by 2016.

Spring milk is produced mainly from grazed grass but, like a lot of land in west Tipperary, drainage is a problem.

In 2011, the Ryans decided to allow one of their fields into a drainage research project.

With backing from their local Tipperary Co-op (and other co-ops) they committed to draining a five-acre field for the project.

The Teagasc specialists visited the farm to assess the type of drainage that would best suit the land.

Led by Pat Tuohy and James O’Loughlin, they decided that deep drains at 1.6m deep (5ft) was the best way to drain this type of land.

In the past, the Ryans had done some drainage in the top three feet but, as Pat Tuohy explained, that would be fine to take surface water but it wasn’t going to drain the land because the water was moving in the gravel and permeable layer, which was between 1.5m and 2m from the surface.

Reading the test hole

Pat explained: “You can see in the test hole a very shallow, dark top soil followed by an orange, tacky-type layer that is at least 1m deep with high clay content.

“After that, we meet a lot of moving water in a stony, sandy layer that is crumbling away from the side of the test hole.

“In this hole, we have dug down over 2m but you can see at 1.5m to 1.6m the water oozing out of the sides of the hole so that’s where the water is moving.

“It means that is where you need to put your pipe and stone drain and take that water to an outlet.

“In this field, we are very lucky to have a drain that is moving away perpendicular from the drained paddocks beside the farm roadway.”

Beside the trial paddock is a paddock that was not drained to act as a control – to compare performance to the area drained.

Within the drained area, they dug deep drains either at 30m apart or at 15m apart.

The drains were dug and then an 80mm drainage pipe was placed down and stone filled only 1ft over the pipe and then the drain was backfilled with the orange-type clay that came out.

At the walk last week, there were lots of questions about whether to use a pipe or not, type of stone, why not use more stone and bring to surface and what to do if you hadn’t an outflow, etc.

Pipe or no pipe

On the pipe or no pipe issue, Pat Tuohy explained: “The idea of using a pipe is to move the water away faster.

“Since we installed these drains last July, there is water flowing through the pipes.

“Some suggest stone alone will allow the water to move away, and it will of course, but the pipe helps to move that water faster, especially on a long drain like we have here between 110m and 130m long.

“More people say the pipes only allow iron to build up faster on the inside of the pipes and block them, but we think the new jet wash systems can help wash them out.”

As you can see from Figure 1, the pipe is only a small percentage of the cost of the job in Rossmore and in the other drainage projects.

On the type of stone, Owen Fenton of Johnstown Castle said there is a lot of nonsense talk about round stone being better but if you can get a clean stone between 10mm and 40mm in size, it normally does a very good job.

He said: “Don’t use very small stone (less than 10mm), round or square doesn’t really matter and try to get the stone free from dirt.”

Many farmers at the walk said this was a perfect (easy) field to drain because there was a good outflow and the levels allowed the field to drain.

They asked what would you do if you hadn’t an outflow or if the outflow level was higher than the field which needed to be drained.

Pat Tuohy said: “In that type of a scenario, you might have to dig deep drains down to the gravel layer again and then, every 10m, create a sump hole which would build up with water and then take that water to the outflow at a higher level than the permeable layer.

“In this field, we dug the drains out from the floor of the stream, which is about 1.6m from the surface.”

Stone to surface

On bringing the stone to the surface, Pat said: “There is no problem bringing stone to the surface in places where you have a hollow of water or where you are collecting run-off from a steep hill, but be clear on your objective because it adds cost.

“On this job, we only covered the pipe with 1ft of stone and then backfilled in the clay dug-out on top and hence we used a lot less stone.”

A farmer asked the question would hump and hollow drainage help?

Pat responded: “If you have your own machine and don’t count your own labour, it can be cost-effective but comparing like with like, it can come to the same cost as deep drainage and you might not drop the soil water levels.

“That type of drainage is more suited to taking run-off water from the soil in heavy downpours.”

Another farmer asked if you dig a test hole and you don’t get water seeping in, what do you do?

Pat said: “You might then have to look at shallow drainage (mole plough-type drainage) and put in deep drains around the paddock or something like that.

“Everything is site-specific so if you are going to spend money then try to ensure you’re doing the right job to get the right result.

“You can see here on this farm that the Ryans did some drains 3ft down from the surface a few years ago and while they will take surface water, you can see there is no water running in them now but the deep drains are continually flowing because they are in the gravel layer where the water is moving.”

Kennedy’s view

There is no doubt, the minute you develop a plan for drainage you are going to spend big money so you need to be clear how you aim to get a return for that investment.

From Figure 1, you can see for the seven commercial farms in this project that the drainage cost alone varies from €3,000 per hectare (€1,200/acre) right up to over €7,000 per hectare (€2,800/acre) for one of the farms in west Limerick.

For many farms, the first thing you need to do is get the basics right by cleaning existing boundary drains to get the water flowing using the old and existing drainage.

Critically, you need to develop a plan and stick to it.

I know full well when the digger is in the field it’s so easy and tempting to move into phase two and three of the plan simply because the digger is there, but make sure you know what you are getting yourself in for because the cost can escalate very quickly.

The cost can be significantly more if the weather and land is wet when the job is being done.

Drainage is a specialist game and what makes it difficult for farmers and researchers alike is almost every field is different, so the solution can vary a lot.

What makes it more difficult is that there are a lot of unanswered questions in the whole drainage area and local variations in pipes, stones, drainage types, etc.

All of these, however, are no excuse for getting the fundamentals wrong, such as proper diagnosis of the problem, proper planning on the solution and proper management once the job is done.

Drainage is only one leg of the stool and soil fertility, the right grass species and good grazing management all must fall into place after the digger moves out.

Therefore, ensure you have the necessary funds for that also – fencing, roadways, reseeding and improving soil fertility. It’s a package deal and without one leg of the stool it falls over.

Performance summary

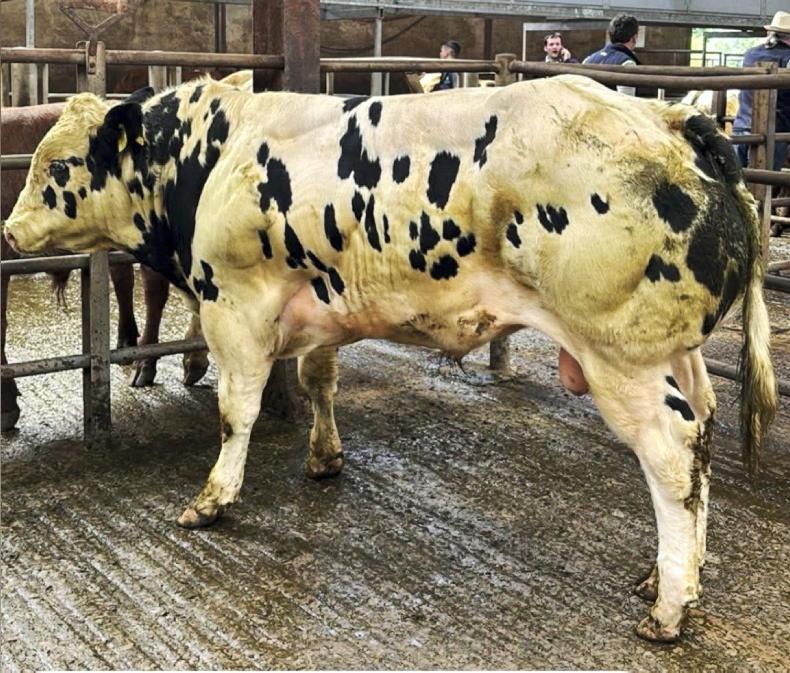

British Friesian-based herd with Holstein Friesian AI sires used for a number of years. Good herd fertility with 75% of herd calved in six weeks in 2014. Milk production last week was 25kg per cow at 3.74% fat and 3.26% protein (1.75kg MS/cow) on grazed grass and 2kg of meal. Last year, herd average produced was 352kg of milk solids per cow. Farm cover last week was 460kg DM/ha (160kg/LU) with growth rate at 60kg/day and demand set lower at 46kg/day. Surplus paddocks taken out as round bales.

SHARING OPTIONS