Last week, Kerrie Brown returned home to her family’s beef and sheep farm near Florencecourt, Co Fermanagh, after a six-month work placement on a Canadian dairy farm close to the city of Windsor in southwestern Ontario near the Canadian-US border.

As part of the professional studies element of her degree in agricultural technology at Queen’s University Belfast, Kerrie worked on Bally Bright Farms owned by William and Vicky Morrison, originally from Waringstown, Co Down. The 300-acre farm has 155 Holstein cows in a fully housed system.

A supply management system in the form of quotas in Canada limits the number and size of dairy herds. In Essex county, where the farm is situated, there are 11 dairy farms in an area the same size geographically as Co Fermanagh, with Bally Bright one of the largest units. Dairy units in Canada tend to be a lot smaller than over the border in the US where there is no quota system, noted Kerrie.

The Canadian quota system is based on butterfat, with Bally Bright having an allowance of 200kg of butterfat per day. Due to demand being slightly ahead of supply for the last three months, dairy farmers in Ontario have been issued with an extra three days of quota each month. This is known as ‘‘incentive days’’ and the scheme is expected to continue into 2016.

Kerrie said that quota is not readily available for Canadian dairy farmers and requires a significant investment costing approximately $24,000 per kilo of butterfat. Every month, available quota is auctioned and divided out accordingly among bidders. Last month for example, the Morrisons acquired 0.51kg of additional quota.

The Morrison herd is yielding around 36 litres per cow at 4.1% butterfat and 3.45% protein, meaning quota and available incentive days are being filled at around 1.47kg butterfat per cow per day.

Butterfat

The aim on the farm is to maximise butterfat per cow, so that the number of cows needed to fill quota is as low as possible.

The current target is to reach 1.5kg butterfat per cow per day. The monthly quota system also means that cows calve throughout the year to have a consistent supply of milk from the herd.

The farm is planted with maize and a mix of grass and alfalfa. Maize on the farm typically yields around 20t/acre at 60% dry matter.

The mix of grass and alfalfa is cut four times a year from late May to September. In a wet time, grass becomes more dominant in the crop, and in periods of low rainfall alfalfa grows more strongly.

In the cow barn, the alfalfa-grass mix is fed at a ratio of 33% to 66% of maize. The high-yielding cows get 7.5kg of concentrates fed in the mix and the low-yielding group gets 6.5kg.

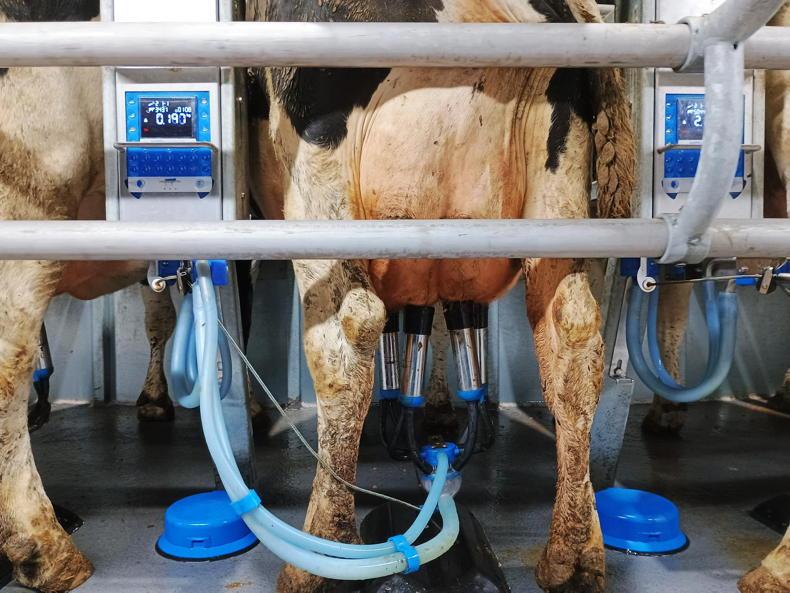

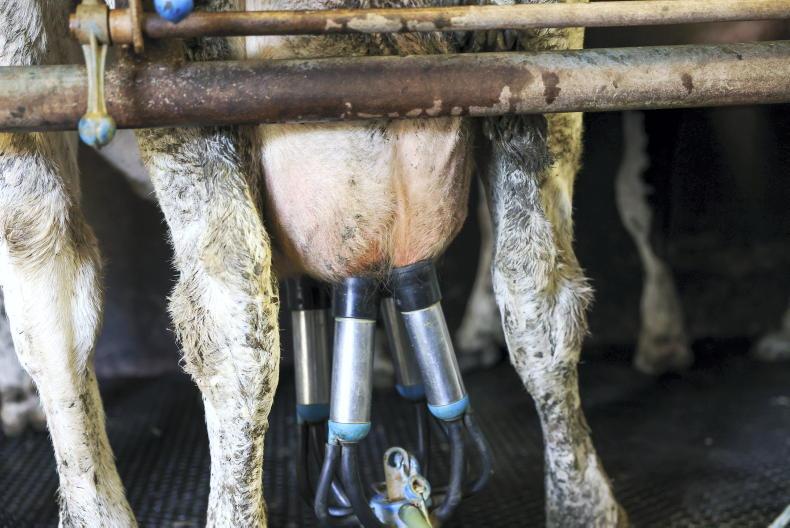

“There are no in-parlour or out-of-parlour feeders. During milking all cows are stripped, pre-dipped, wiped, milked and then post-dipped. The 10-a-side double-up rapid exit Boumatic parlour was there when the Morrisons bought the farm in 2013 after moving from another farm in Ontario. Milking usually took around three hours,” Kerrie said.

Approximately 935mm of precipitation falls in Ontario annually and temperatures can range from 35oC in the warmest month of July to -20oC in the coldest month of January.

Housing

The extremes in climate mean that the cow barn is insulated with plywood. Some sheds in Ontario have false ceilings with blown-in insulation. Turkey curtains are used on the sides to allow ventilation in summer and stop the wind in winter.

“Cubicles are bedded with sand and at every milking any dung is raked off the cubicles when the cows are out. Once a week, the cubicles are topped up with a sand slinger, which is a similar idea to a stone cart used for draining,” Kerrie said.

The barn is built on a slight gradient, so that a flush wash system can be used to clean passages. Manure is flushed through a flume to manure storage pits. The solids tend to settle and the liquid water on the surface is recycled to be used to wash the shed again.

Upbeat

Kerrie described the mood in the dairy sector in Canada as upbeat due to a strong domestic market and limited production managing supply and demand. All milk produced in Essex county is used in a mozzarella cheese factory in Windsor.

There was a degree of uncertainty in the industry a few months back during the Trans-Pacific Partnership Agreement trade talks. A subsequent trade deal allows importers access to 3.25% of the Canadian market, although that was a better result than many in the Canadian dairy industry had anticipated.

The talks also raised questions about the future of supply management in Canada but, since then, farmers have resumed buying quota.

SHARING OPTIONS