Changing shed functions can always cause issues, especially when they have been specifically designed for a dairy purpose originally. In the 90s, the Giblins were milking cows in an old cow byre system. They took the plunge to construct a purpose-built slatted cubicle shed and milking parlour, all under the same roof. The shed is five spans in total, with the first four being standard 4.8m bays. To accommodate the width of the herringbone milking parlour, the final bay is slightly over 6m.

When Martin Giblin took over the farm from his father in 2009, he continued to milk cows, but the pressure of full-time off farm employment meant that the working day was long. Milking started at 5am in order for Martin to be able to get to work for 7.30am. Low milk prices in 2009 were the final nail in the coffin for the dairy enterprise and, as a result, milking ceased and suckler numbers were increased as Martin always had a fondness for suckler-bred stock. This is something that his two sons David and Ciarán carry on; both of them are in college in Galway. When busy in the evenings, Martin’s nephews Jack and Oisín lend a hand with the work also.

Although Martin has two sons who help him out at weekends and during holidays; for the main part, he is farming on his own, so he needed to adapt the shed to meet his needs. The slatted cubicle area originally was all one, and later divided into two, but with cattle numbers increasing, and more groups of stock to be housed, there was a need to alter the shed. The parlour pit was filled and two large, dry-bedded pens created. It is mostly Parthenaise bulls which are used on the cows. Martin has purchased an all-round five-star Parthenaise bull, and is delighted with calf quality and calving ease so far.

Picture one

Two calf creep areas were created in the old milking parlour. Gibney gates were purchased to divide pens as they are strong and telescopic, which meant that they were easily fitted. Calf creep areas can easily be accessed by a tractor for cleaning or power washing.

Pictures two and three

For any suckler farmer, calving gates are essential. Martin has put two calving gates into the shed, one in the calf creep area and one in a smaller passage, which was used by the dairy cows to cross from one side of the shed to the other.

In picture two, we see that Martin has a winch placed on a wall bracket over the calving gate. This exists so that the calf can be winched out of a cow when a caesarean section is carried out, but it has not been used so far. The availability of the winch gives Martin added peace of mind if a caesarean is taking place with limited help. The calving gate in the calving pen is specifically designed for calving cows. It has a gate that opens to allow C-sections. The other gate is mainly for injecting/dosing an individual animal within the confines of the shed without having to move her out to the crush. It is mainly used for serving cows to AI when they are still in the shed.

Martin has also got two calving cameras set up over the calving pens. This allows him to use his phone to check cows in the pens when he is not in the yard. He also has a MooCall, which is used for heifers and problem calvers.

Originally, the shed was in two large sections. By putting in dividing gates, Martin has now created nine separate divisions in the shed. This allows him to house dry cows, calved cows, heifers, bullocks and yearlings in separate areas of the shed.

The centre of the shed was fitted with two cow cubicles, which were walled the sides.

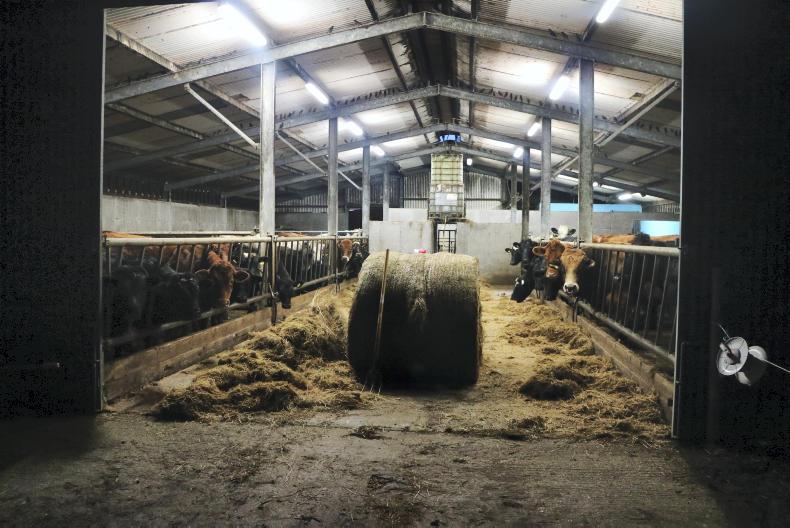

To create more feeding space, the cubicles were removed and short feed barriers were put in place, so that the feeding area was close to the central pens of the shed. A loader drops round bales of silage over a 5ft wall into the feeding area.

Picture six

To the side of the shed is a full-length crush, which runs for approximately 25m. There are two gates along the side of the crush which can be opened out if required; one is halfway down and the other is at the front of the crush.

Martin has designed the crush in such a way as to be able to move cattle from one side of the shed, through the crush and back into the other side on his own.

The uprights are made of 5ft lengths of steel railway girders, so the crush is strong and built to last. They are spaced about 8ft apart, or two per bay.

At the entrance to the crush, the bars have been shaped into a curve. This has two major benefits, the first being that cattle move around the turn more freely entering the crush. The second is that the curved nature means that there is no upright, or sharp end in the yard making it easier for machinery to navigate around it. At either end of the shed, there are gates and posts which fit into sleeves so they can be easily and quickly erected when cattle have to be moved.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: