With dairy farmers expanding herd size and investing in larger milking parlours it is of utmost importance to maintain a regular wash routine and use the most effective detergents to uphold a premium quality milk.

The way in which farmers use detergents can have significant effects on milking equipment and if used incorrectly, detergents can leave chemical residuals and can wear or crack rubberware. It is essential that farmers mix detergent solutions at the recommended levels to ensure effective cleaning and avoid any formation of chemical residuals.

The Irish Farmers Journal spoke to Teagasc’s David Gleeson regarding correct procedures when using detergents.

Detergent composition

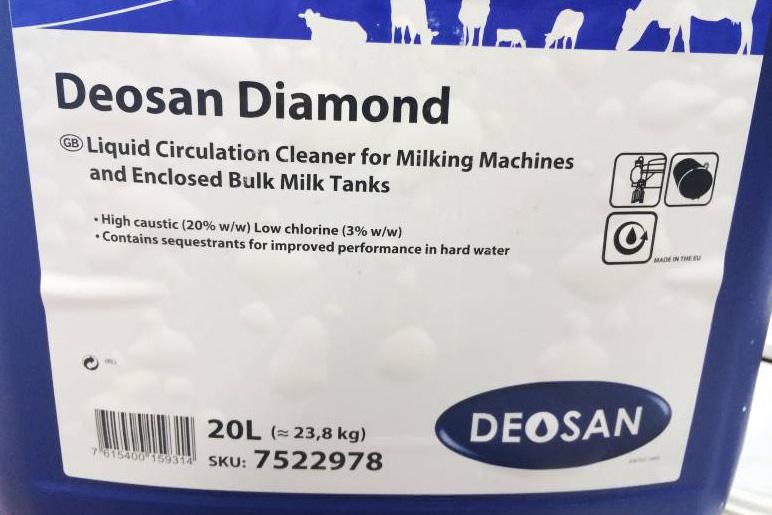

Detergent-sterilisers contain varying levels of caustic and chlorine. Caustic facilitates the cleaning of milk equipment, while chlorine acts as a sterilising agent.

The percentage of caustic and chlorine in a detergent will determine whether it is suitable for a hot or cold main wash or if it can be re-used.

Detergent-sterilisers with less than 10% caustic are not suitable where cold water is used for the main wash cycle. Farmers intending to re-use a detergent or use a detergent in a cold main wash should ensure that the product contains more than 12% caustic for effective cleaning.

When purchasing detergent-sterilisers, farmers should select products with a chlorine content of less than 3.5%.

Detergents containing more than 3.5% chlorine are excessive and unnecessary. Too much chlorine or inadequate rinsing can have severe implications on milking equipment and milk quality.

Excessive chlorine (greater than 3.5%) can result in the formation of chemical milk residuals such as trichloromethane (TCM) and chlorate residuals. Both can negatively affect the quality of your milk and taint your milking equipment.

Maintaining milk quality

To maintain low TCM and chlorate levels, farmers need to ensure that correct cleaning procedures are in place.

Farmers should ensure that the milking machine is rinsed after the main wash cycle with 14 litres of water per milking unit.

Farmers are required to have TCM levels of less than 0.0015mg/kg. To comply with this, farmers must avoid using products with a high chlorine content, try to reduce re-using the same detergent cleaning solution and stop dipping clusters in chlorine.

From a survey conducted on farms where TCM levels are high, the main problems were farmers not using enough rinsing water to remove detergent (63%), cleaning bulk tank with too much detergent (26%), not rinsing detergent out directly after the main wash (25%) and recycling detergent more than once (19%).

The presence of chlorate residues in milk has become a new emerging concern for farmers. Chlorate residuals in milk has been directly attributed to high chlorine contents when washing the milking machine.

In addition, factors such as age of a detergent and storage conditions will also influence chlorate residual levels.

Prolonged storage of detergent-sterilisers and exposure to sunlight during storage can result in the formation of chlorate residuals in milk when detergents are used.

Farmers are recommended to purchase detergent-sterilisers as close as possible to their manufacturing date, avoid bulk storing and minimise exposure to direct sunlight.

Detergent-sterilisers are important to remove milk deposits,but farmers are also advised to conduct a weekly descale or acid wash to ensure the removal of mineral deposits which can remain within the milking machine.

Farmers must ensure to use detergents that have a pesticide control service (PCS) number.

Basically, the PCS number indicates that a detergent is registered with the Department of Agriculture and can be legally used.

Use of PCS numbers

The use of PCS numbers provides a guide to farmers and informs farmers which products are approved by the Department and verifies the composition of caustic and chlorine contents in a particular detergent.

It is worth noting that farmers who do not use registered detergents may be in breach of cross compliance and may risk facing penalties to their Basic Payment Scheme.

Bord Bia inspectors also require farmers to use only registered, approved detergents with a valid PCS number to ensure compliance with the quality assurance scheme.

A survey conducted concluded that 5% of farmers are using ‘‘unapproved detergents’’.

SHARING OPTIONS