The main culprits that hack up the saw include hitting stones; surprisingly, soil is one of the biggest enemies of the chain. Fencing wire is also a nasty surprise to find in some trees.

Damaged cutters can be filed back to new by picking the worst one and filing all of the remainder, left and right, down to the same top cutter length. This length can be judged by the Mark One Eyeball or by measuring with a callipers if you want to be more precise. The guides in front of the cutter will also need to be filed down to match them.

A good rule of thumb is that the guides get a rub every third cutter filing.

Actual chain sharpening is where many of us fall down, often bringing it into the dealer to get a ‘‘good edge’’ on it after making a mess of sharpening. Sharpening is not a dark art, it is pure geometry. Once you can identify the chain, then you can get the necessary data such as sharpening angles, guide height and file sizes.

Picture one

The first and easiest place to find chain data is on the rear of the box the chain comes in. This is a typical chain featuring a round ground chisel, so a 5.5mm file is used to sharpen it. The cutter angle across the head is 25 degrees, with a 10-degree drop. The height between the top of the cutter and the guide is 0.65mm.

Picture two

There are various devices to aid correct sharpening; some work better than others, but the main thing is to find one you can use and understand. In this picture, there is an electric sharpener from Lidl on the far left and a new one to me was the Stihl sharpening device on the far right.

Picture three

This Stihl sharpener is very easy to use and sharpens the cutter, while at the same time filing down the cutter guide. So, it does all operations in one movement.

Line it up as the arrow indicates and with the plastic holders parallel to the bar as shown. It is one of the easiest to use for sharpening devices manually.

Picture four

This is a popular file guide often seen on farms around the country, with the angles marked on the flat section of the guide. It requires a bit more skill to use correctly with different cutters.

Picture five

This version slips on to the bar and the file runs on two rollers to give the 10-degree cutter angle. The 25-degree top angle is achieved by keeping the file parallel to the sides of the guide. Some chains – ones by Stihl in particular – have a flat top plate, so it is important to check before you sharpen. After sharpening, break off any exposed flakes of chrome with the file handle so it doesn’t get peeled off in use.

Picture six

After approximately every third sharpening, it is a good idea to check the cutter guides and file down, if necessary, to maintain cutter bite. Pictured is a simple and effective cutter height and file guide, which allows for quick assessment and filing if necessary. The Stihl sharpener does this automatically.

Picture seven

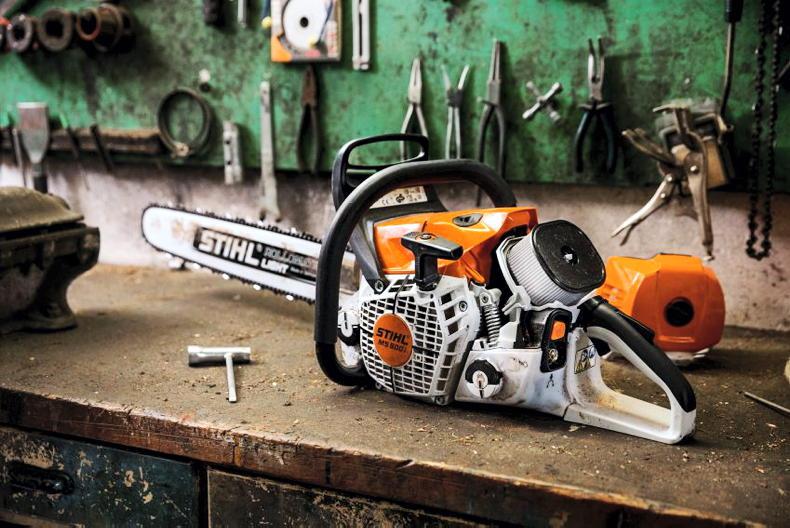

Often neglected, the chain guide bar needs maintenance as well. The chain track needs to be clean for oil to lubricate the chain properly. Note the smaller hole above the two fixing holes. This is to allow oil access to the guide bar and, if it is blocked, the chain cannot be oiled. Also, data on the guide bar indicates the chain guide width, chain pitch and number of links, so if you are not sure what replacement chain to buy, this information will be of benefit to the dealer.

Picture eight

Everyone has different ideas about how to tension a chainsaw chain. A basic rule of thumb is that you should be able to hold the middle of the chain up. When released, it should snap back into the bar and you should still be able to manually turn the chain on the bar.

Picture nine

The drop test checks the function of the band brake’s inertia trip. When the saw is switched off, drop the nose from about 16in on to a wooden block, which should bring on the band brake. If it doesn’t, then the mechanism needs to be checked out.

Again, it’s very easy to neglect saw maintenance and good practice is to change the spark plug every year before the sawing season kicks off. This will help to avoid unnecessary hassle.

Air-filter cleaning is a daily need on most saws that are getting any amount of use. Check and clean as necessary to avoid stress on the saw and excessive fuel consumption.

SHARING OPTIONS