The clean livestock policy for sheep was introduced about a year ago by the Department of Agriculture, Food and the Marine. It was established following a consultation period with industry stakeholders and aims to safeguard Ireland’s domestic and export sheepmeat and hide trade.

While the policy has been in place for the last year, it has come more into the spotlight in recent weeks due to greater challenges in presenting sheep in the required condition for slaughter.

This has, in cases, led to some sheep being rejected for slaughter until remedial action has been taken. This includes delaying slaughter and allowing sheep time for their fleece to dry or shearing to reduce the risk of contamination during the slaughter process.

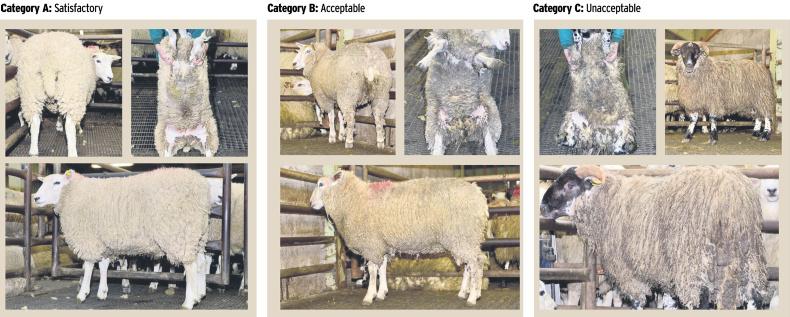

The major element of the policy is a three-category system which slaughter-plants must use to denote the condition and suitability of sheep presented for slaughter.

The policy states that each processing plant must provide photographic examples of each of the three categories at the entrance to the lairage in each slaughter plant.

The Department has provided photographs to demonstrate the type of animals falling into each category, as shown here.

Furthermore, the number of sheep falling into each category must be recorded. The policy recommends that “to ensure a process of continuous improvement, over time, the processor should provide feedback to herdowners/keepers on the condition of their animals presented for slaughter eg - by giving the number of animals by CLP category; by providing photographic evidence, where necessary, of the condition of the animals”.

In the case of category A animals, the policy states that no intervention is required outside of standard hygienic dressing procedures.

For category B animals, the policy states that the factory must ensure than an intervention takes place to reduce the risk of contamination.

One example listed in the document is the removal of wool from either side of cut lines in a well-ventilated area immediately after bleeding and prior to entry into the dressing area.

Other additional or alternative options are allowed provided they achieve the desired outcome.

Highest risk

Category C animals pose the greatest risk and are deemed unacceptable for slaughter. The policy states that the food business operator (FBO – slaughter plant) must take the required steps to rectify the condition of animals.

As mentioned previously, this can range from drying the fleece to shearing animals before presenting for examination pre-slaughter. The policy adds that each FBO must also have a standard operating procedure in place, which sets out how category C sheep will be dealt with, and agreed with the Department.

Category A: Satisfactory

This reflects sheep in a similar or cleaner condition to the one shown – sheep that can be slaughtered, without an unacceptable risk of contaminating the meat during the slaughter process, by using the standard hygienic dressing procedures routinely employed by the plant.

Category B: Acceptable

This reflects sheep in a similar or cleaner condition to the one shown – sheep that can only be slaughtered, without an unacceptable risk of contamination of the meat during the slaughter process, by putting in place additional interventions including extra defined dressing controls.

Category C: Unacceptable

This reflects sheep in a similar or dirtier condition to the one shown – sheep unfit for slaughter because of fleece condition. These sheep must not be presented for ante-mortem in this condition and it is the responsibility of the FBO to take the required remedial action.

Reducing the risk

The category C animal shown on page 41 has a high level of fleece contamination which has built up over a period of time.

It is important to note that clean animals are at risk of falling into this category if they are not handled correctly.

Examples of this include clean and dirty animals mixing during drafting or handling and sheep with dirty tail-ends or scouring contaminating other sheep, with the risk of this heightened where lambs are wet.

Other examples include animals being transported in dirty trailers or lambs becoming soiled from seepage from upper decks.

The responsibility for adhering to the clean livestock policy falls collectively on the shoulders of farmers (or owner of the sheep), the haulier (or person transporting the sheep) and processors. Farmers are the starting point in the supply chain and, as such, can have the greatest influence.

The Department has highlighted a number of recommendations, while Teagasc has developed an advice leaflet for farmers and hauliers to help prevent any issues occurring.

Implementing a robust health programme and paying particular attention to a worm and fluke control programme to reduce the incidence of scouring will greatly help. Outside of this, Teagasc have broken down their recommendations to concentrate on a number of different scenarios, as follows.

Finishing at grass

Drafting lambs from a grass-based diet is the most common finishing system practiced in Ireland. The following recommendations can help.

? Where possible maintain dry underfoot conditions and move finishing lambs to clean pasture when swards become muddy. Target drier areas for grazing in the run-up to slaughter.

? Excess nitrogen fertiliser or very lush grass will bring about more scouring with the advice to avoid such conditions during the finishing stage.

? If supplementing, move troughs or feeders regularly to limit poaching and fleece contamination.

? Situate drinkers at a height and on drier areas providing hardcore areas if needed to keep areas mud-free.

? Avoid routine free access to mineral supplements and instead treat animals for specific mineral and vitamin deficiencies.

? If conditions are not suitable to draft lambs straight off grass then there may be no option but to house animals temporarily.

Forage/root crops

Finishing lambs on forage crops became more popular in the last two years given the increased availability of forage crops planted to meet cross compliance and the Green Low-Carbon Agri-Environmental Scheme (GLAS) requirements.

? Inclement weather has restricted opportunities for shearing lambs. Teagasc advise crutching or dagging lambs before turning onto crops.

? Sheep should be allowed time to adjust to the new diet by restricting access and providing a grass runback or free-access to hay.

? Similar to supplementation at grass, if supplementing with concentrates or hay, move feeding points regularly to avoid poaching.

? Sheep should have a dry lying area to limit soiling of the fleece. On free draining soils, the crop itself may provide this. On heavy soils, or during wet weather, Teagasc advise that a grass runback or straw-bedded area should be provided.

Finishing indoors

? Animal should be finished in a well-ventilated shed that is suitable for the job at hand.

? Shearing will help to keep lambs cleaner but is not vital. Trials have shown no increase in animal performance between shorn and unshorn lambs.

? In straw-bedded sheds, replenishing straw regularly and adhering to recommended stocking rates will help greatly.

? In slatted sheds, ensuring slats do not become blocked is important in preventing a build-up of soiled material.

? Allow adequate space at troughs and keep on top of any lameness issues.

? Try and house animals dry.

Selecting the most appropriate finishing diet

The finishing diet offered can have a significant influence on the cleanliness of lambs. There has been a sharp increase in recent weeks in the number of farmers supplementing finishing lambs with the aim of combating the low dry matter content and lower feeding value of grass along with improving daily liveweight and slaughter performance. The following Teagasc recommendations can help prevent feeding-issues related to high-concentrate finishing diets.

? Increase levels of concentrates slowly and avoid sudden changes to the diet to prevent dietary upsets and scouring.

? Avoid feeding low dry matter diets (low DM silage, beet etc.).

? Feed rations that are properly balanced for fibre, energy and protein.

? Avoid feeding excess salt as this increases water intake and urine production. Note also to include Ammonium Chloride at 0.5% of the finishing diet to protect against urinary calculi.

? If feeding high-starch diets avoid finely ground ingredients - feed a percentage of the cereal in whole or cracked form.

Pre-sale management and transport advice

The way animals are managed in the run-up to sale can have a big bearing on their suitability for slaughter. Firstly, animals should be handled in an environment that gives the best opportunity to prevent fleece contamination. Handling animals on straw-bedding, slats or appropriate bedding will deliver more suitable working conditions than concrete or a soiled hardcore area for example.

Where animals have been grazing on wet underfoot and muddy conditions then the best option may be to house animals and allow time for the fleece to dry out. Processors can better handle animals that are dry and somewhat soiled over those that are soiled and wet. Lambs with dirty tail-ends should be dagged. It is advisable to withdraw feed before transport as this will greatly cut down on the potential for lambs to soil one another. Teagasc recommended withdrawing feed for a minimum of eight hours and a maximum of 12 hours with animals offered free access to water at all times. For animals travelling long distances it is important to liaise with your processor.

Lambs transported incorrectly can put the entire group at risk of failing to meet the required cleanliness. For example, one lamb with a dirty tail-end or scouring can contaminate the fleece of many more, particularly if lambs are wet when loading. For this reason it is important to adhere to the recommendations listed above. The following Teagasc guidelines are also important to follow.

? Only clean stock deemed fit for transport should be loaded.

? Only persons with experience of moving/ handling stock should be involved in loading and unloading. Ensure correct handling to maintain animal welfare and avoid carcass damage.

? Avoid mixing groups or batches of livestock and use solid partitions/dividers to separate groups.

? Provide sufficient space for animals in transit (see Table 1).

Absorbent materials should be used on the floor where. Where decks are in use, ensure that faeces /urine from higher decks do not soil sheep on lower decks.

Table 1. Recommended space allowance for different categories of sheep

Category Weight (kg) Area in m2 /animal

Shorn 26 to 55 0.2 to 0.3

Shorn Over 55kg 0.3

Unshorn Under 55kg 0.3 to 0.4

Unshorn Over 55kg 0.4

Source: Council Regulation (EC) 1 of 2005 on the protection of animals during transport and related operations

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: