When you meet Darren, you get the feeling this man knows his brief, has well-thought-out reasoning behind most of his decisions and is well able to communicate those decisions.

It might not always be what you expect, but Darren usually has some way to adapt to suit Monaghan circumstances. Public roads presented a challenge to business development that Darren wasn’t going to let get in the way of grazing cows. He has two road underpasses, one in front of the farmyard and one down in a hollow which is L-shaped under another public road near the farm. It’s drumlin country so Darren also has plenty of hills and hollows, flowing water and bridges and yet he moves cows around the farm bothering nobody. When cows are inside Darren also has integrated new with old buildings to bring all stock movement under cover, minimising waste water and unnecessary water collection.

Darren McKenna and family with Michelle McCafferty, LacPatrick and the Quality Milk judges

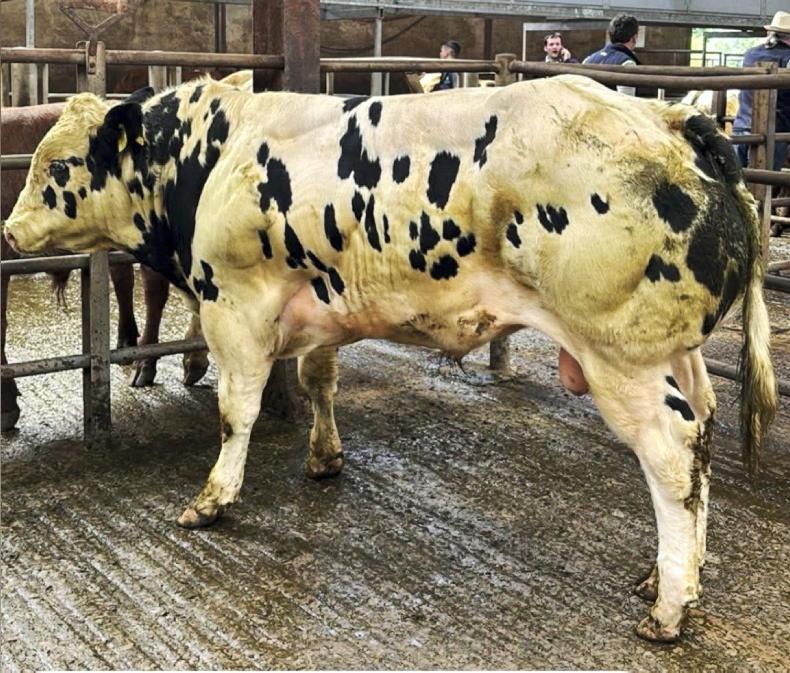

At one stage Darren was heading for 10,000 litre pedigree Holstein cows but when he researched and watched others he saw his current system of producing about 6,000 litres per cow from 800kg of meal/cow/year as more sustainable long term, with better herd health and fertility key to better profits.

Darren is the fifth generation to farm at Derrygasson and the real push on investment came in 2007 when sheds, parlour and tunnels were constructed to allow him build the cow numbers from 60 to 90 by 2017 and up to 105 cows this year.

In total, 62ha are farmed, with 33ha available for grazing. Meal fed is about 800 kg per cow and grazed grass is in the diet for 10 months of the year. With 37 heifer calves and 26 in-calf heifers, Darren might be able to milk 130 cows in the coming years.

Darren has separate detachable clusters units hanging up at the back of the parlour for milking cows that are infected which he attaches if needed to milk a cow with a high cell count cow rather than using the normal cluster and risking cross-contamination. Milk is produced all year round with 50,000 litres (10%) supplied from November to January inclusive. Darren uses headlocking barriers for vaccinating cows or any other work and finds this important for ease of handling on a one-labour-unit farm.

Darren built two underpasses to allow cattle move around the farm.

Darren has an autowasher for plant washing. A hot wash circulates every morning with a cold wash in the evening. No chlorine is used in the detergent and the plant is acid descaled once a week. Darren has an electrical conductivity software to measure inline conductivity from each cow as she is milked. This and observing milk socks, pre-stripping cows prior to milking helps identify any mastitis early. While Darren says the conductivity measure is not 100%, it helps to confirm other suspicions.

When you meet Darren, you get the feeling this man knows his brief, has well-thought-out reasoning behind most of his decisions and is well able to communicate those decisions.

It might not always be what you expect, but Darren usually has some way to adapt to suit Monaghan circumstances. Public roads presented a challenge to business development that Darren wasn’t going to let get in the way of grazing cows. He has two road underpasses, one in front of the farmyard and one down in a hollow which is L-shaped under another public road near the farm. It’s drumlin country so Darren also has plenty of hills and hollows, flowing water and bridges and yet he moves cows around the farm bothering nobody. When cows are inside Darren also has integrated new with old buildings to bring all stock movement under cover, minimising waste water and unnecessary water collection.

Darren McKenna and family with Michelle McCafferty, LacPatrick and the Quality Milk judges

At one stage Darren was heading for 10,000 litre pedigree Holstein cows but when he researched and watched others he saw his current system of producing about 6,000 litres per cow from 800kg of meal/cow/year as more sustainable long term, with better herd health and fertility key to better profits.

Darren is the fifth generation to farm at Derrygasson and the real push on investment came in 2007 when sheds, parlour and tunnels were constructed to allow him build the cow numbers from 60 to 90 by 2017 and up to 105 cows this year.

In total, 62ha are farmed, with 33ha available for grazing. Meal fed is about 800 kg per cow and grazed grass is in the diet for 10 months of the year. With 37 heifer calves and 26 in-calf heifers, Darren might be able to milk 130 cows in the coming years.

Darren has separate detachable clusters units hanging up at the back of the parlour for milking cows that are infected which he attaches if needed to milk a cow with a high cell count cow rather than using the normal cluster and risking cross-contamination. Milk is produced all year round with 50,000 litres (10%) supplied from November to January inclusive. Darren uses headlocking barriers for vaccinating cows or any other work and finds this important for ease of handling on a one-labour-unit farm.

Darren built two underpasses to allow cattle move around the farm.

Darren has an autowasher for plant washing. A hot wash circulates every morning with a cold wash in the evening. No chlorine is used in the detergent and the plant is acid descaled once a week. Darren has an electrical conductivity software to measure inline conductivity from each cow as she is milked. This and observing milk socks, pre-stripping cows prior to milking helps identify any mastitis early. While Darren says the conductivity measure is not 100%, it helps to confirm other suspicions.

SHARING OPTIONS