Price volatility, specialist knowledge and bio-security concerns all make starting a pig venture daunting. However, with the UK a net importer of pigmeat, Scottish specialist pig abattoirs and a steady supply of domestic grain, diversifying a farm into finishing pigs could help complement an arable, mixed or livestock farm.

Farmers Journal Scotland spoke to Andy McGowan of the co-op marketing group Scottish Pig Producers and Iain Lyle, monogastric technical support manager at Harbro to find out how start a pig finishing business.

To demonstrate what is needed to start finishing pigs, we set a premise of a farmer with a spare shed along with access to farm machinery from an existing arable and/or livestock business. This is the advice Andy and Iain had for someone considering starting out.

Getting started

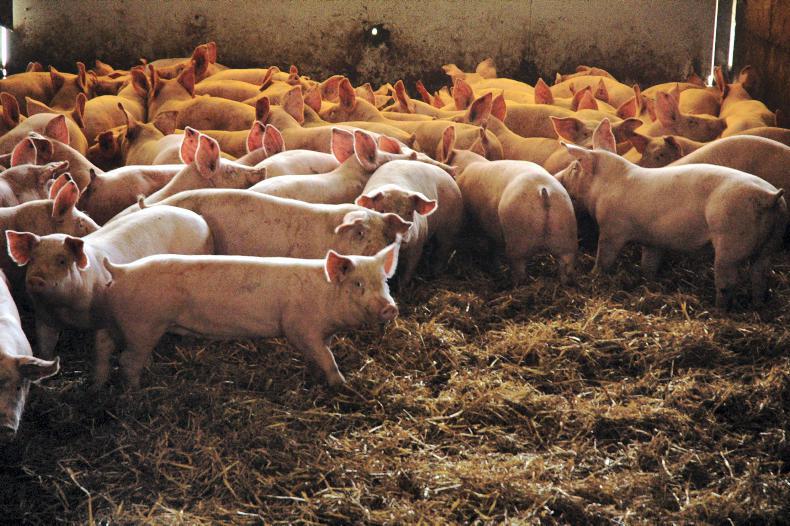

On a 80×50ft concrete floored shed you will be able to keep 360 weaners at a time. The system would be to bring a batch to finish, wash down then start a fresh batch again. This way you will get around three and a half batches per year.

Buying weaners

To get the weaners you will need to contact a marketing group who can put you in touch with a producer who will have some for sale. Expect to pay around £45 for a 30kg pig at around 12 weeks of age. This price has varied between £30-£55/head in the last few years.

The breed will be a mix of different commercial lines with varying proportions of Large White, Landrace, Duroc and Hampshire genetics. You will likely take both sexes and treat them in a single batch. Some cutting-edge producers, finishing over 10,000 pigs a year separate the males from the females and provide more tailored diets, but for a simple small finishing shed, it is not worth the hassle.

Running an ‘all-in then all-out’ batch system allows you to buy weaners for a different supplier for each batch if needed. It is not advisable to mix batches from different farms for health reasons. However, most established pig finishers build up relationships with producers over the years.

There is usually a two-week window when 30kg pigs are suitable to be moved between farms.

Finished price

Once finished, farmers currently get £115/head which has been quite stable for the last couple years. However, prices have ranged from £100 to £130 in recent times. If going through a marketing company, payment is made once the kill sheet has been sent out. Prices are set based on a weekly spot price.

To sell the pigs most farmers go through one of the marketing co-ops Scotlean or Scottish Pig Producers. The biggest abattoir for pigs in Scotland is Quality Pork Processors at Brechin. Ardrossan in Ayrshire, with Dingwall and Grantown also killing smaller numbers every week.

Pig feed

For a small starter finishing unit it’s most likely to be cost effective to use pelleted feed from a mill. This will be predominantly grain based (barley, maize of wheat) with protein (often soya and sometimes fishmeal) and a mineral mix. The main suppliers in Scotland are Harbro, ABN, East Coast Viners and For Farmers. Farmers who grow cereals can use their own grain with mobile mills adding in the protein and minerals. This can be a cost-effective way to finish pigs and worth investigating. Both Norvite and Harbo offer this service.

A finisher diet for 30kg weaners is currently costing around £235/t. To bring a weaner to finish takes around 192kg of feed which will cost around £50/head.

Small-scale finishers should be able to achieve growth rates of between 700-850g a day when starting at 30kg. Top-notch Scottish producers are able to achieve over 1kg a day.

Weaners will be finished at 115kg liveweight which turns into a 85kg carcase. This has risen by around 3-4kg in the last four to five years. Kill out percentage is consistently around 76% due to the regular genetics. Penalties for out-of-spec pigs can range from £1-£70 based on weight, fat levels and health. For carcases under 70kg or over 105kg expect high penalties.

Farmers need to weigh some pigs every week with more thorough weighing the closer to finish. Towards the end of a typical 105-day finishing period pigs will be growing 5-6kg a day so attention to growth rates is vital to hit spec.

A 360-pig batch will fit into two wagon loads as a typical haulier will be able to take up to 180 pigs at a time. Pigs can be delivered in your own livestock trailer if it can safely handle them and is farm assured. This can all be arranged through the a marketing co-operative. They will also help cover the official movement documentation with is run through ScotEID. Haulage typically costs £3.50/pig for Scottish producers but this can vary depending on the length of the journey.

Bedding

The amount of straw used for bedding can vary significantly but a rough industry standard sits at around four pigs per bale during the batch. Barley and wheat straw works well with rape straw lacking in absorption qualities. Further the straw acts as an insolation helping to keep pigs warm.

Alternative bedding is also an option with wood chips and waste both used in Scotland. However it is important to ensure it doesn’t breach any assurance guidelines before buying.

Bio-security

Good health and bio-security is vital for a profitably pig finishing farm. Nevertheless as there are very few diseases which pass between pigs and ruminants so it is perfectly possible to run a pig unit alongside a sheep or cattle farm.

They key to maintaining a low disease burden is running ‘an all in and all out’ system. This allows sheds to be washed down and disinfected between batches.

Disease threats to look out for

Similarly to most housed livestock the disease threats and respiratory diseases like pneumonia along with enteric diseases like scour. It is recommended you speak to a specialist pig vet who will be able to set a health plan. There are around six vet groups in Scotland who have specialist pig knowledge. Medicines for pigs cost between £1-£5/head on average depending on the disease risk.

Issues like tail biting should not be an issue as the straw bedding will help stimulate the pigs. Further there is no need to buy toys in a straw bedded shed.

Equipment

Farmers will need to buy feeders, drinkers and stock boards to equip their shed for pigs. A recent new entrant to the pig sector set up a 300 pig unit for less than £5,000. Pigs are far more adept at getting through gaps than sheep or cattle. Their wedged-shaped head and higher intelligence means that farmers need to use stock boards to ensure no escapees. Wood boards will work but they are less able to be disinfected between batches.

Weigh scales are a good idea for pig farmers however some new entrants have been able to use sheep scales when getting started.

Pigs are moved on a batch system and do not currently need the level of individual identification which cattle and sheep require. Marketing co-ops help to co-ordinate movements along with hauliers to ensure records are kept for Government legislation.

Bed and breakfast option

For farmers looking for another income stream but don’t want the volatility, contract finishing someone else’s pigs is another option. It has the benefit of having a fixed income and can be a good route into the industry. Whilst it won’t make massive amounts of money it is less risky and can complement an arable or livestock business cash flow. Typical contact prices vary depending on who is produce the inputs but pig marketing co-ops are able to put entrants in touch with pig farmers if there is an interest.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: