Renewable energy has long been a feature on Eoin McCambridge’s farm near Ballycastle, on the scenic north Antrim coast.

With the main farmyard bordering the River Carey, the McCambridge family has been harnessing the power of water for decades.

Eoin’s father originally installed a mechanical water turbine on the river back in the mid-1940s. It served multiple purposes over the years, from milling grain to generating electricity for the farmhouse and outbuildings.

Water is diverted from the river with a 7m fall into the turbine.

Back in 2006, a new 30kW turbine was commissioned to replace the old turbine, which had reached the end of its working life.

Grant funding was available at the time, making the investment possible, as did the UK government’s green energy initiatives such as renewable obligation certificates (ROCs).

A sluice gate controls the water intake.

Since then, Eoin has ventured into other areas of renewable energy with land now used to grow willow, which is sold as a domestic fuel source.

Eoin runs a mixed farming enterprise on his 67ha (165 acres) unit, of which 52ha (128 acres) is grassland and the other 15ha (37 acres) is in willow.

Sheep are the only livestock on farm, although there had been a small dairy herd of 45 cows up until the early 2000s.

The current sheep flock consists of around 480 March-lambing ewes with a strong emphasis on Lleyn, Suffolk and Belclare genetics.

The farm is laid out in two large land blocks with a mix of dry land close to the home yard and heavier soils on the outfarm, which is where ewes are housed for lambing.

Hydro power

Eoin opted for a German-made cross flow turbine as it offered higher levels of efficiency due to the way water flows through the internal mechanism.

Water makes contact with the turbine’s internal rotors twice, firstly as it enters the top of the turbine and again at the bottom as water exits, creating double the driving force.

The water is filtered to remove debris.

The 30kW cross flow turbine was commissioned in 2006 and replaced an older turbine installed in the 1940s.

“The other big advantage of the turbine is there are two power cells inside, known as a one-third: two-thirds flow,” explains Eoin. “It means during summer or in a dry spell when the river levels are lower, the turbine closes down the larger two-thirds side, forcing more water through the narrower one-third side.

“As water is forced through the smaller inlet, it creates pressure and keeps the turbine running efficiently. When the river levels are higher, the two-thirds side opens. Both inlets are automatically controlled by sensors. The inlets gradually open and close to suit the water flow.

“The turbine works on a full flow rate of 0.5 cubic metres of water per second to generate the 30kW/hour.”

Environmental benefits

The turbine is powering the farmhouse and buildings with the surplus exported to the grid. Eoin says: “We export between 150,000kW and 200,000kW annually from the turbine, which is powering 30 homes locally and reducing CO2 emissions by 80t/year.

“In the past year, energy prices have increased and, thankfully, this has filtered through to a higher price for the electricity we export to the grid. We also receive two ROC payments for every kW, so the turbine is a good income source for the farm.”

Two biomass boilers dry woodchip on farm.

The dried chip is sold for fuel.

Planning was required as the River Carey is a key fishing water. Eoin was required to build a fish pass to allow salmon and trout migrate upstream for spawning.

Environmental bodies regularly conduct checks to monitor water quality and ensure that the weir constructed to control water flow is allowing adequate water downstream.

Successful hydropower comes down to site location. On Eoin’s farm, a weir with a sluice gate controls the water diverted from the river to the turbine. The river feeding the turbine has a natural fall of 7m from the sluice gate to the engine house, creating plenty of pressure to force water through the system.

Filters remove all debris and escape routes are mandatory to release any fish without harm and there are built-in safety mechanisms to deal with flood water.

Eoin also grows willow on 15ha (37 acres) across five sites on farm. Introduced back in 2006, the first crop was harvested in 2010.

The crop is managed in a staggered manner to provide willow for harvesting every year.

Once cut, it takes three years for the crop to regrow and reach harvesting stage again.

Willow is grown on 15ha.

Although it has been a relatively successful venture, there has been required significant investment made over the years.

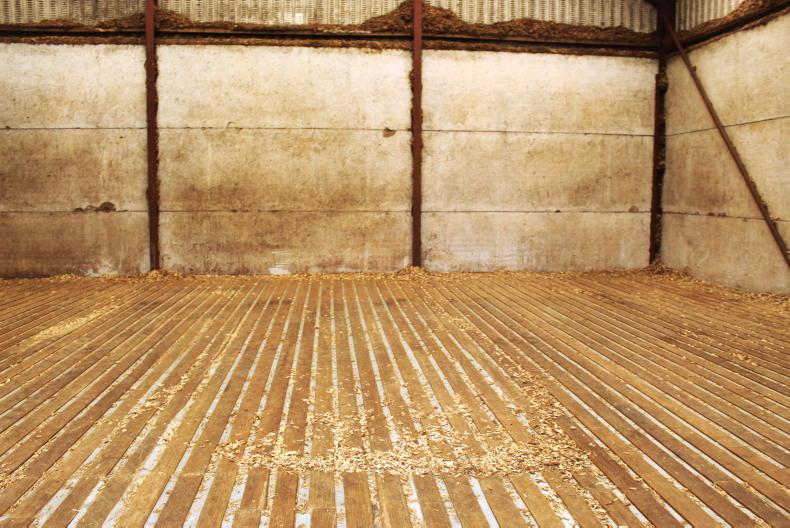

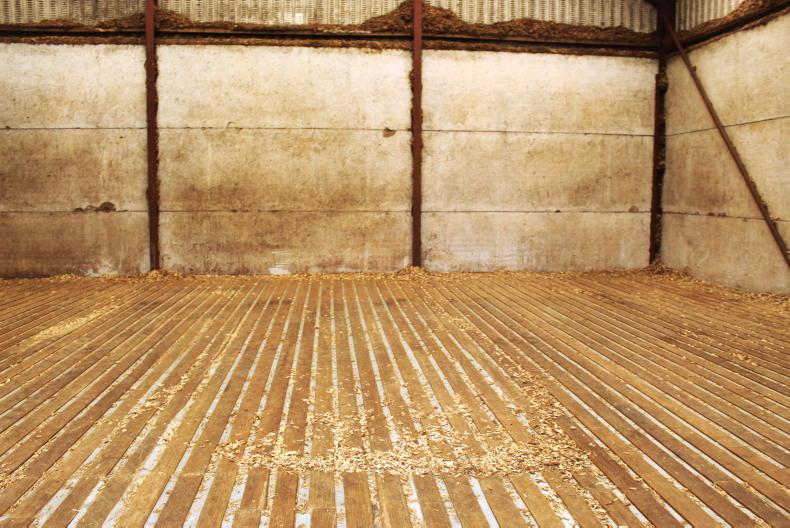

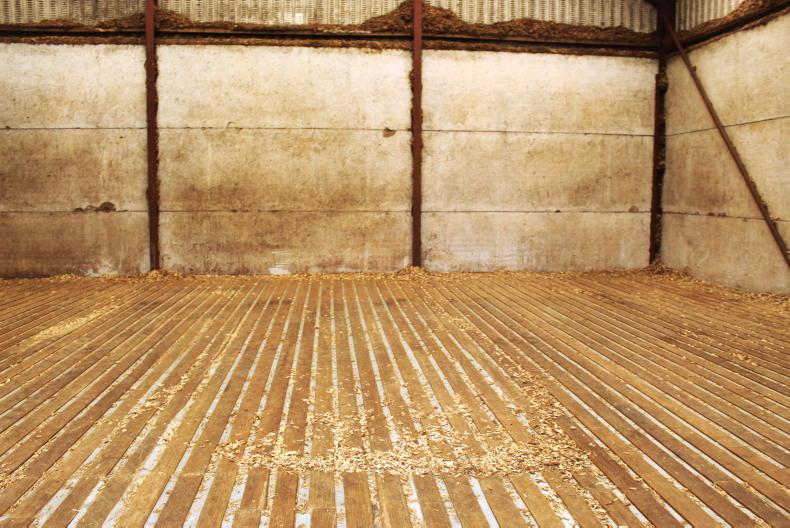

A drying shed was erected in 2010 and, at the time, gas was the main fuel source used to blow hot air through the drying floor.

When filled to capacity at harvest time, the shed holds 300t of wet willow (55% DM) which is then dried down to 18% DM, leaving around 150t of dry, chipped willow.

A shed with a drying floor was erected in 2010. Willow is chipped at harvest, then dried down from 50% moisture to 18%.

Removing so much moisture was expensive, even at gas prices of five to 10 years ago.

The decision was then taken to switch to biomass boilers with the decision helped by the availability of the RHI payments.

Two biomass boilers were installed in 2016 at a cost of £40,000 per unit. Unfortunately for Eoin, the RHI “Cash for Ash” scandal hit the mainstream news headlines in Northern Ireland around the same time.

This ultimately brought an end to payments for using biomass on farm, leaving him to pay for the boilers without any financial assistance after just one year of getting aid.

However, he is happy to have made the switch, especially given energy costs in 2022. Wet woodchip is now dried in just over two weeks with the biomass boilers, less than half the time it took with gas.

Chip is supplied on contract to one client based in the Republic of Ireland, destined for manufacturing into domestic fuel.

Management

“It’s a very low-cost, low-maintenance crop. No fertiliser is required to grow the crop and harvesting occurs in autumn once leaves have fallen off the willow. We get a contractor to harvest it with a self-propelled forager and two trailers,” Eoin says.

Yields are holding up well, although I would expect tonnage to start tailing off soon as the crop has a 25-year lifespan before it needs replacing.”

Always keen to look at ways to diversify, Eoin’s experiences with renewables is leading him to look at the potential for solar power on farm. “It’s always good to take a look and see what is out there.”

67ha farm with 52ha of grassland and 15ha in willow.480 March-lambing ewes.Using biomass boilers for drying woodchip.Water turbine powers farm and exports to grid.

Renewable energy has long been a feature on Eoin McCambridge’s farm near Ballycastle, on the scenic north Antrim coast.

With the main farmyard bordering the River Carey, the McCambridge family has been harnessing the power of water for decades.

Eoin’s father originally installed a mechanical water turbine on the river back in the mid-1940s. It served multiple purposes over the years, from milling grain to generating electricity for the farmhouse and outbuildings.

Water is diverted from the river with a 7m fall into the turbine.

Back in 2006, a new 30kW turbine was commissioned to replace the old turbine, which had reached the end of its working life.

Grant funding was available at the time, making the investment possible, as did the UK government’s green energy initiatives such as renewable obligation certificates (ROCs).

A sluice gate controls the water intake.

Since then, Eoin has ventured into other areas of renewable energy with land now used to grow willow, which is sold as a domestic fuel source.

Eoin runs a mixed farming enterprise on his 67ha (165 acres) unit, of which 52ha (128 acres) is grassland and the other 15ha (37 acres) is in willow.

Sheep are the only livestock on farm, although there had been a small dairy herd of 45 cows up until the early 2000s.

The current sheep flock consists of around 480 March-lambing ewes with a strong emphasis on Lleyn, Suffolk and Belclare genetics.

The farm is laid out in two large land blocks with a mix of dry land close to the home yard and heavier soils on the outfarm, which is where ewes are housed for lambing.

Hydro power

Eoin opted for a German-made cross flow turbine as it offered higher levels of efficiency due to the way water flows through the internal mechanism.

Water makes contact with the turbine’s internal rotors twice, firstly as it enters the top of the turbine and again at the bottom as water exits, creating double the driving force.

The water is filtered to remove debris.

The 30kW cross flow turbine was commissioned in 2006 and replaced an older turbine installed in the 1940s.

“The other big advantage of the turbine is there are two power cells inside, known as a one-third: two-thirds flow,” explains Eoin. “It means during summer or in a dry spell when the river levels are lower, the turbine closes down the larger two-thirds side, forcing more water through the narrower one-third side.

“As water is forced through the smaller inlet, it creates pressure and keeps the turbine running efficiently. When the river levels are higher, the two-thirds side opens. Both inlets are automatically controlled by sensors. The inlets gradually open and close to suit the water flow.

“The turbine works on a full flow rate of 0.5 cubic metres of water per second to generate the 30kW/hour.”

Environmental benefits

The turbine is powering the farmhouse and buildings with the surplus exported to the grid. Eoin says: “We export between 150,000kW and 200,000kW annually from the turbine, which is powering 30 homes locally and reducing CO2 emissions by 80t/year.

“In the past year, energy prices have increased and, thankfully, this has filtered through to a higher price for the electricity we export to the grid. We also receive two ROC payments for every kW, so the turbine is a good income source for the farm.”

Two biomass boilers dry woodchip on farm.

The dried chip is sold for fuel.

Planning was required as the River Carey is a key fishing water. Eoin was required to build a fish pass to allow salmon and trout migrate upstream for spawning.

Environmental bodies regularly conduct checks to monitor water quality and ensure that the weir constructed to control water flow is allowing adequate water downstream.

Successful hydropower comes down to site location. On Eoin’s farm, a weir with a sluice gate controls the water diverted from the river to the turbine. The river feeding the turbine has a natural fall of 7m from the sluice gate to the engine house, creating plenty of pressure to force water through the system.

Filters remove all debris and escape routes are mandatory to release any fish without harm and there are built-in safety mechanisms to deal with flood water.

Eoin also grows willow on 15ha (37 acres) across five sites on farm. Introduced back in 2006, the first crop was harvested in 2010.

The crop is managed in a staggered manner to provide willow for harvesting every year.

Once cut, it takes three years for the crop to regrow and reach harvesting stage again.

Willow is grown on 15ha.

Although it has been a relatively successful venture, there has been required significant investment made over the years.

A drying shed was erected in 2010 and, at the time, gas was the main fuel source used to blow hot air through the drying floor.

When filled to capacity at harvest time, the shed holds 300t of wet willow (55% DM) which is then dried down to 18% DM, leaving around 150t of dry, chipped willow.

A shed with a drying floor was erected in 2010. Willow is chipped at harvest, then dried down from 50% moisture to 18%.

Removing so much moisture was expensive, even at gas prices of five to 10 years ago.

The decision was then taken to switch to biomass boilers with the decision helped by the availability of the RHI payments.

Two biomass boilers were installed in 2016 at a cost of £40,000 per unit. Unfortunately for Eoin, the RHI “Cash for Ash” scandal hit the mainstream news headlines in Northern Ireland around the same time.

This ultimately brought an end to payments for using biomass on farm, leaving him to pay for the boilers without any financial assistance after just one year of getting aid.

However, he is happy to have made the switch, especially given energy costs in 2022. Wet woodchip is now dried in just over two weeks with the biomass boilers, less than half the time it took with gas.

Chip is supplied on contract to one client based in the Republic of Ireland, destined for manufacturing into domestic fuel.

Management

“It’s a very low-cost, low-maintenance crop. No fertiliser is required to grow the crop and harvesting occurs in autumn once leaves have fallen off the willow. We get a contractor to harvest it with a self-propelled forager and two trailers,” Eoin says.

Yields are holding up well, although I would expect tonnage to start tailing off soon as the crop has a 25-year lifespan before it needs replacing.”

Always keen to look at ways to diversify, Eoin’s experiences with renewables is leading him to look at the potential for solar power on farm. “It’s always good to take a look and see what is out there.”

67ha farm with 52ha of grassland and 15ha in willow.480 March-lambing ewes.Using biomass boilers for drying woodchip.Water turbine powers farm and exports to grid.

SHARING OPTIONS