It is recommended that suckler farms should have at least one calving box for every 10 cows. This is where the cow and calf only remain in the box for one to two days. If there is a tight calving spread, more calving pens will be needed. The boxes should be at least 3.6m x 4.0m in area.

Calving pens should be thoroughly clean, power-washed and disinfected with a strong disinfectant before use. Don’t skimp on straw around calving time – it’s very important that calves have a clean dry bed in their first days of life.

Check the availability of basic calving equipment – things like disposable gloves for handling cows, spare calving ropes, iodine solution to treat navels, a clean calving jack that is not worn or liable to slip, lubricant, electrolyte powders for scour treatment and a clean stomach tube.

Frozen colostrum is a good insurance policy where there is inadequate supply or for the 4am calving. Good-quality minerals should be fed to dry cows for a minimum of six weeks pre-calving.

New calving unit in Monaghan

The Harte family, just outside Clones, Co Monaghan, have recently made the transition from finishing cattle to operating a large suckler herd. With this transition came the need to upgrade their facilities for both wintering suckler cows and calving them.

Tommy and Aidan Harte commissioned a purpose-built calving unit in 2016 with the main steel work carried out by Conaty Steel Ltd and the internal kitting out with calving gates, etc, supplied by Teemore Engineering in Fermanagh.

The calving unit, while it is under its own roof, forms part of a larger suckler unit. Cows are bedded on peat (the family business is Harte Peat/Peat Bed) and eat along a passageway with automatic scrappers.

All main pens have adjoining creep areas for young calves. The calving unit is designed so that one man can move a cow into the calving unit at any one time.

Gates open out on to the passageway to direct cows into individual pens. The unit has six individual pens, each with their own calving gate. Each pen also has a locking barrier so that if cows and calves need to be tended to for any reason, they can be safely restrained while the operator enters the pen.

Tommy comments: “Having people employed, we are very safety conscious and health and safety was at the top of our list when we designed the unit. Every year we hear of cows attacking farmers at calving time and we wanted to have ours as safe as possible.”

Calving gates

“We have assembled a small pedigree herd over the past few months and future plans are to work with a small number of elite females via embryo transfer. With this in mind, and a high number of caesarean sections coming, we invested heavily in purpose-built calving pens where caesareans can be completed.”

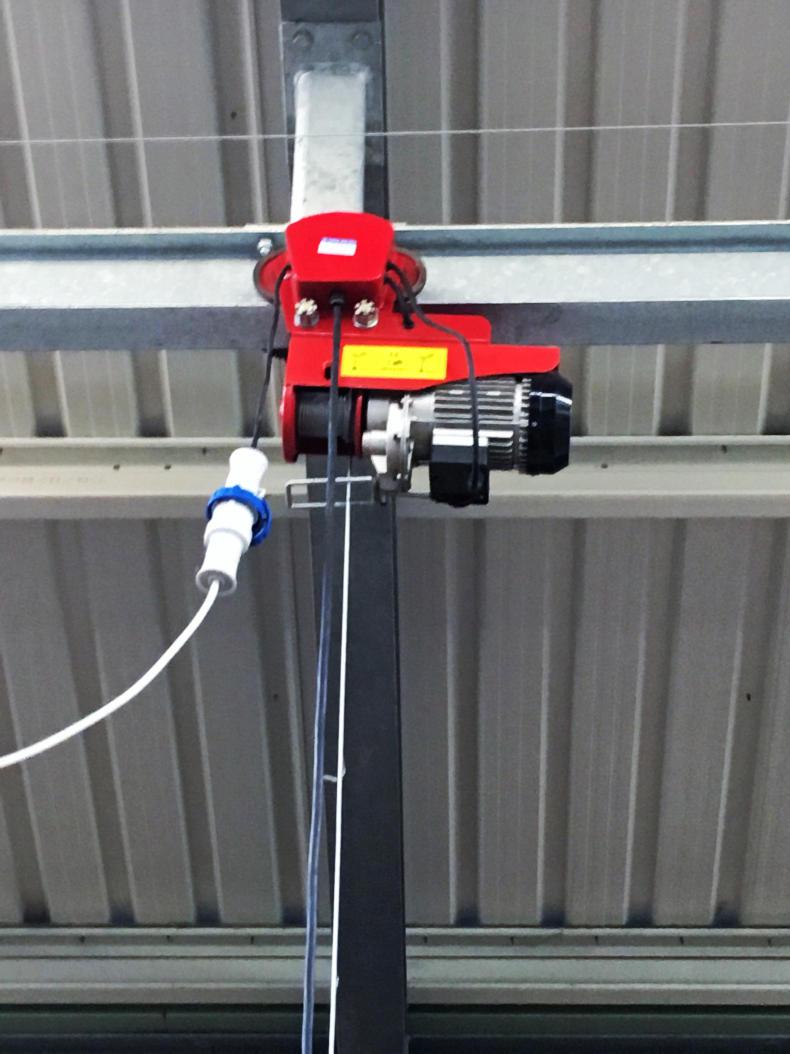

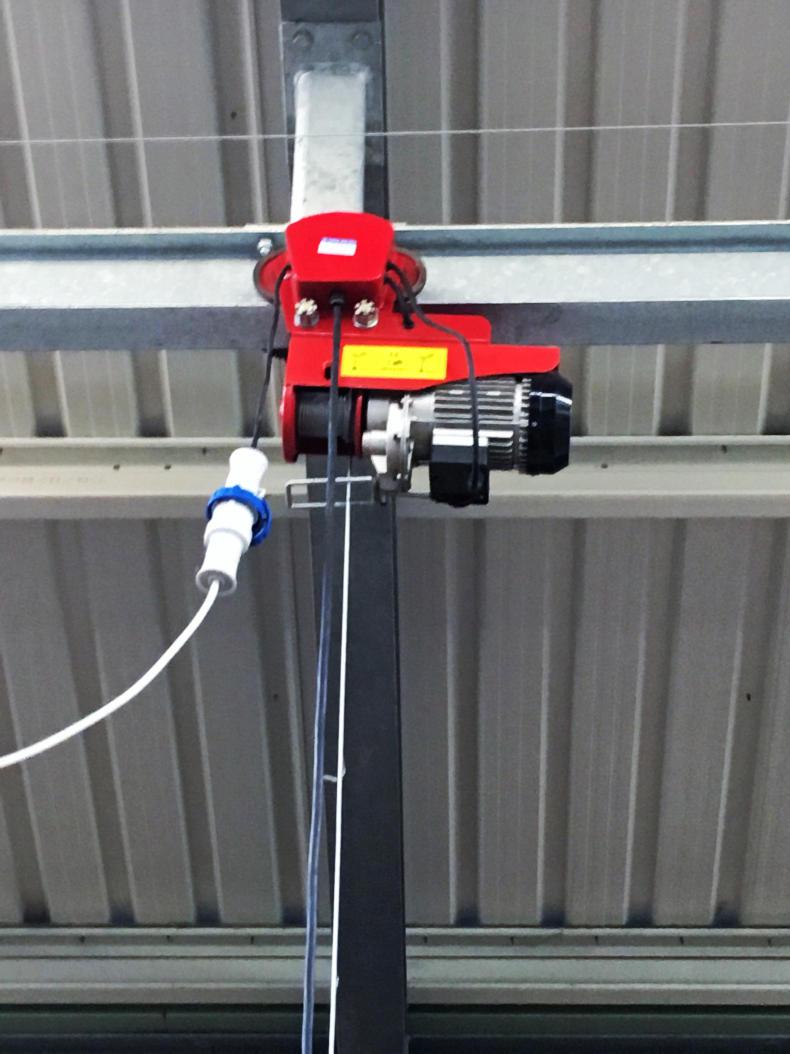

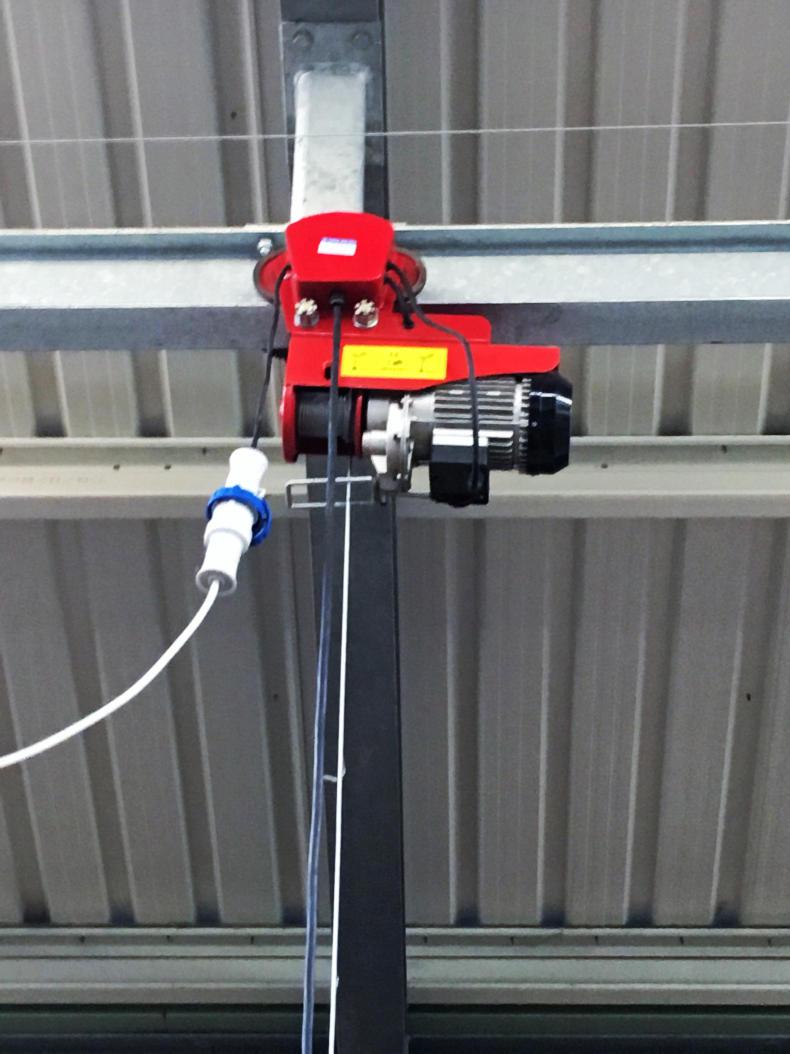

A simple winch system has been installed where embryo calves can be lifted out, decreasing the need for a second person to be present at a c-section. The head-lock unit of each calving goes to the ground, which is very important to prevent choking if the cow falls during calving.

Health and safety

Each pen is designed so that the operator does not need to enter the pen along with the cow. The full section of the gate swings around so the cow has no choice but to enter the head lock. The smaller section can then be chained so the cow is secured for calving.

After calving, there are automatic head locks in place so that if a calf needs treatment or a cow needs attention, a cow can be caught with a small amount of concentrates. Escape gates are installed in each pen. If an operator gets caught they can use the man escape to exit the pen quickly.

Ventilation

While ventilation is very important in cattle sheds to avoid problems like pneumonia, the elimination of low draughts is equally important to avoid problems.

This shed has two ways of eliminating these draughts. Roller doors are fitted on either end of the passageway, which blocks any low draughts. The gates at the end of the calving pens are also covered in rubber mats to stop any draughts from blowing in on young calves. Higher up, a combination of vented sheeting and open space ensures there is adequate inlet and outlet space to elimate stale air in the shed.

Ensuring good colostrum intake

Farm manager Niall McGovern explained the protocol when calves hit the ground on the Harte farm.

“We keep calving pens as clean as possible during calving. After each calving, calving pens are cleaned out and disinfected with Stalosan powder.

“Cows are generally moved to individual pens one day before calving to allow them time to settle. Once a calf is born, the navel is sprayed with iodine and the calf receives one litre of colostrum to 10kg birth weight up to a maximum of four litres within two hours.”

Niall commented: “ It’s sometimes hard to know with heifers what the colostrum yield is like, so this autumn we are milking all heifers and cows with a mobile milking machine so we can make sure that all calves have received adequate colostrum.

“If a heifer doesn’t milk three litres, we have a frozen supply that we can thaw out and feed. The issue is knowing what cow has adequate supply and what cow hasn’t – the milking machine gives us peace of mind.”

When asked how sucklers took to clusters, Niall answered: “Surprisingly well. Once the cow is restrained in the calving gate, there generally isn’t a problem. Colostrum yield this autumn has ranged from 200ml to four litres, which is a massive spread in one herd.

“The unit cost €800 and if it saves one calf it’s paid for.”

Hygiene

A wash area with a hot water supply and sink was installed in the calving shed to ensure good hygiene at calving time. This is extremely useful, especially when hot water is needed. A freezer was also installed in this area for ease of access to frozen colostrum. A simple white board is used for details of new calvings and any notes or interventions required. Gloves are worn at all times to protect both the cow and the operator.

Read more

Focus on winter indoor management

It is recommended that suckler farms should have at least one calving box for every 10 cows. This is where the cow and calf only remain in the box for one to two days. If there is a tight calving spread, more calving pens will be needed. The boxes should be at least 3.6m x 4.0m in area.

Calving pens should be thoroughly clean, power-washed and disinfected with a strong disinfectant before use. Don’t skimp on straw around calving time – it’s very important that calves have a clean dry bed in their first days of life.

Check the availability of basic calving equipment – things like disposable gloves for handling cows, spare calving ropes, iodine solution to treat navels, a clean calving jack that is not worn or liable to slip, lubricant, electrolyte powders for scour treatment and a clean stomach tube.

Frozen colostrum is a good insurance policy where there is inadequate supply or for the 4am calving. Good-quality minerals should be fed to dry cows for a minimum of six weeks pre-calving.

New calving unit in Monaghan

The Harte family, just outside Clones, Co Monaghan, have recently made the transition from finishing cattle to operating a large suckler herd. With this transition came the need to upgrade their facilities for both wintering suckler cows and calving them.

Tommy and Aidan Harte commissioned a purpose-built calving unit in 2016 with the main steel work carried out by Conaty Steel Ltd and the internal kitting out with calving gates, etc, supplied by Teemore Engineering in Fermanagh.

The calving unit, while it is under its own roof, forms part of a larger suckler unit. Cows are bedded on peat (the family business is Harte Peat/Peat Bed) and eat along a passageway with automatic scrappers.

All main pens have adjoining creep areas for young calves. The calving unit is designed so that one man can move a cow into the calving unit at any one time.

Gates open out on to the passageway to direct cows into individual pens. The unit has six individual pens, each with their own calving gate. Each pen also has a locking barrier so that if cows and calves need to be tended to for any reason, they can be safely restrained while the operator enters the pen.

Tommy comments: “Having people employed, we are very safety conscious and health and safety was at the top of our list when we designed the unit. Every year we hear of cows attacking farmers at calving time and we wanted to have ours as safe as possible.”

Calving gates

“We have assembled a small pedigree herd over the past few months and future plans are to work with a small number of elite females via embryo transfer. With this in mind, and a high number of caesarean sections coming, we invested heavily in purpose-built calving pens where caesareans can be completed.”

A simple winch system has been installed where embryo calves can be lifted out, decreasing the need for a second person to be present at a c-section. The head-lock unit of each calving goes to the ground, which is very important to prevent choking if the cow falls during calving.

Health and safety

Each pen is designed so that the operator does not need to enter the pen along with the cow. The full section of the gate swings around so the cow has no choice but to enter the head lock. The smaller section can then be chained so the cow is secured for calving.

After calving, there are automatic head locks in place so that if a calf needs treatment or a cow needs attention, a cow can be caught with a small amount of concentrates. Escape gates are installed in each pen. If an operator gets caught they can use the man escape to exit the pen quickly.

Ventilation

While ventilation is very important in cattle sheds to avoid problems like pneumonia, the elimination of low draughts is equally important to avoid problems.

This shed has two ways of eliminating these draughts. Roller doors are fitted on either end of the passageway, which blocks any low draughts. The gates at the end of the calving pens are also covered in rubber mats to stop any draughts from blowing in on young calves. Higher up, a combination of vented sheeting and open space ensures there is adequate inlet and outlet space to elimate stale air in the shed.

Ensuring good colostrum intake

Farm manager Niall McGovern explained the protocol when calves hit the ground on the Harte farm.

“We keep calving pens as clean as possible during calving. After each calving, calving pens are cleaned out and disinfected with Stalosan powder.

“Cows are generally moved to individual pens one day before calving to allow them time to settle. Once a calf is born, the navel is sprayed with iodine and the calf receives one litre of colostrum to 10kg birth weight up to a maximum of four litres within two hours.”

Niall commented: “ It’s sometimes hard to know with heifers what the colostrum yield is like, so this autumn we are milking all heifers and cows with a mobile milking machine so we can make sure that all calves have received adequate colostrum.

“If a heifer doesn’t milk three litres, we have a frozen supply that we can thaw out and feed. The issue is knowing what cow has adequate supply and what cow hasn’t – the milking machine gives us peace of mind.”

When asked how sucklers took to clusters, Niall answered: “Surprisingly well. Once the cow is restrained in the calving gate, there generally isn’t a problem. Colostrum yield this autumn has ranged from 200ml to four litres, which is a massive spread in one herd.

“The unit cost €800 and if it saves one calf it’s paid for.”

Hygiene

A wash area with a hot water supply and sink was installed in the calving shed to ensure good hygiene at calving time. This is extremely useful, especially when hot water is needed. A freezer was also installed in this area for ease of access to frozen colostrum. A simple white board is used for details of new calvings and any notes or interventions required. Gloves are worn at all times to protect both the cow and the operator.

Read more

Focus on winter indoor management

SHARING OPTIONS