Kevin Griffin from Tynagh, Loughrea, Co Galway, is putting the finishing touches to his three-bay suckler shed. The shed has a slatted tank on one side and the other side has a solid concrete floor with a calving area.

It was started the last week of May and completed the first week of November 2015. Now all Kevin has to do is finish off cattle-handling facilities that will surround the shed. Kevin has spring-calving suckler cows and this is his first slatted shed. He says the completion of the new shed has made life much easier and because he is a part-time farmer the new facilities allow him to get through work quicker.

Pictures one and two

The shed is three bays long, 3.5m high at the eaves and 5.3m high at the apex. It was erected by Michael Kelly Engineering Ltd. Tegral Agribild Plus sheeting was used in the roof and vent sheeting was used on the sides to help improve ventilation. The doors of the shed usually remain open when cows are housed to further increase the amount of fresh air available inside.

Picture three

The pens are 4.8m square that fit approximately seven cows per pen. The barriers were supplied by Condon Engineering. The barriers and gates were erected by Michael Kelly. The 14’6”slats were supplied by Banagher Concrete. The walls are all mass concrete and are 225mm thick. The tank is 2.4m deep and there are external agitation points at either end. Paul Kelly Construction did the concrete work for the shed and will be organising the laying of the concrete yard for the handling unit. There are nose-fill drinking bowls servicing two pens which Kevin finds very easy to clean.

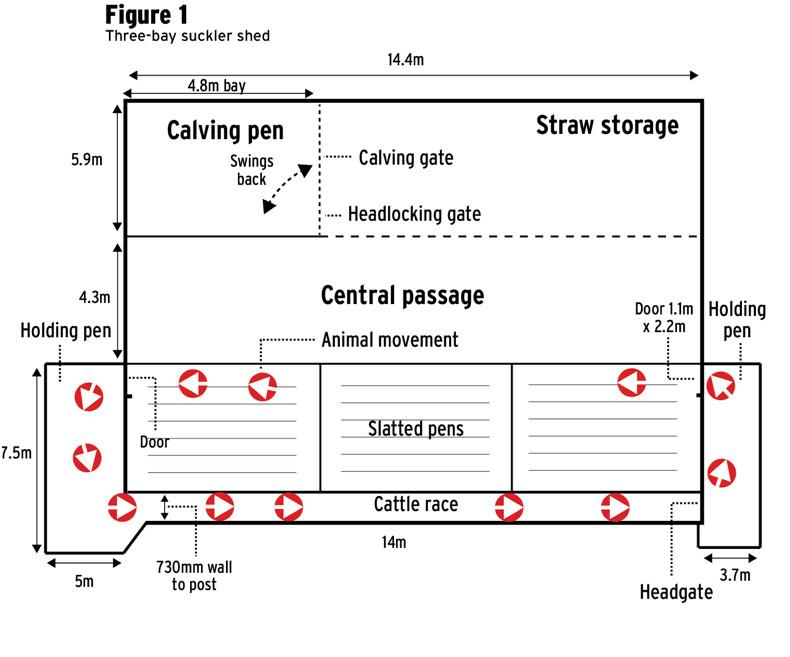

Pictures four and five and Figure 1

The handling facilities in this shed will be a great asset when complete. A door at the gable end of the shed leads out into a holding yard.

From there, cattle can be driven into a race for testing or injecting. The race is 14m long and there is a headgate at the far end. On leaving the race, cattle enter another holding yard. A door in the other gable end of the shed off this holding yard allows cows access back inside the shed.

This is a very simple idea and I think all farmers should consider something similar if they are building a shed in the future. The main benefit is that one person can handle a group of cattle by themselves and it eliminates a lot of the dangers associated with releasing cattle from a shed into open yards for the annual herd test for example. There are steel rails used to make up the cattle race. Ideally, the sides of the race would be swinging gates instead of rigid railings so that the side could be opened easily if an animal went down in the race.

Picture six

The calving pen is large measuring 4.8m x 4.8m. It is usually straw bedded during the winter. It is usually cleaned out by hand after every calving so there is never a build-up of straw to be removed. When cows come close to calving they are drafted to the pen and the calving camera allows Kevin to keep an eye on a cow when he is inside on his phone or iPad.

When the cow is calving and needs assistance the gate can be swung around and a steel chain holds the gate securely against the cow. Calving gates are covered in the farm buildings grant scheme TAMS II and are very beneficial for suckler farmers. Kevin did not apply for a TAMS II grant for his gate. Usually once cows are calved they go straight out to grass. Kevin feels this strategy is far healthier and prevents young calves being exposed to disease.

The remaining area on the left hand side is being use for storing hay and straw. Kevin says he has no plans to change this and finds it useful to have supplies in the shed when they are needed.

Cost

In total, the shed cost approximately €50,000 including VAT. Kevin says he is delighted with how it turned out and is looking forward to completing the handling unit which he says will be the icing on the cake.

Take a tour of the finished shed with our video below:

SHARING OPTIONS