The average herd size in Ireland is increasing. At the moment, it is around 80 cows, but by 2025 this is expected to increase to over 100 cows per farm.

The increase in the average herd size will be largely driven by the exit from milk production of smaller farms and the increase in large herds of greater than 300 cows.

Some of these large herds will be based on new dairy conversions with land that was in beef or tillage being converted to dairy, but it will also be based on expansion within existing farms.

The question on many people’s minds is what is the best way to milk these large herds?

The main considerations are cost and labour input.

The traditional milking parlour options for large herds are either large herringbones or rotary parlours. But other options also exist. A few weeks ago, the Irish Farmers Journal travelled to England to see an alternative milking setup on a new dairy farm.

Houghton Lodge dairy farm is a 1,000ac farm in Leicestershire owned by the charity Farm Care but leased by a farming company called Evolution Farming, which is owned by Tom Rawson, Oliver Hall and Charlie Crotty.

The company owns 2,600 cows on six farms. The farms are run on a mix of arrangements but the company itself doesn’t own any land; it just owns the cows and machinery and manages the farms.

The land leased by Evolution is 1,000 acres but is part of a larger estate at Houghton Lodge of over 4,000 acres, which has been in tillage for decades.

The farm had a dairy unit previously but no cows had been milked for the last 17 years. However, the buildings were still available with a 20-unit milking parlour and straw-bedded housing for cows.

Evolution plans to milk 700 cows on the farm, so it was clear that the 20-unit herringbone milking parlour wasn’t going to be big enough to cater for that amount of cows.

The farm is leased on a 15-year farm business tenancy with the owners putting in all the fixed assets, but getting a 10% return on this investment, along with an annual lease on the land.

“We looked at the various options, including a 48-unit herringbone or a larger rotary. Both options require two operators for maximum throughput, so this got us thinking about installing two smaller herringbones side by side, which are more common in southern England,” Evolution director Tom Rawson explained.

Rotary option ruled out

Tom said that the rotary option was ruled out early on because the cost was higher and because it wasn’t possible to increase the size of it.

The decision then was whether to go with one long herringbone, or two short ones.

While a rotary can be operated by one person, a large herringbone always needs two people, particularly when there are no automatic cluster removers present.

The advantage of the two herringbones side by side is that one parlour can be shut down and the other side kept going so one person can still milk, albeit at only half the output than if two sides were working. It is also possible to add a third parlour.

The length of parlour is also a consideration.

The building for the new parlour was a converted straw-bedded shed and while it was probably large enough to take a 48-unit herringbone, the collecting yard would have had to be pushed back further.

As things stand, the two herringbones fit in next to each other very neatly.

In terms of cost, Tom says that the two 24-unit herringbones cost about £30,000 (€33,600) more to install than one 48-unit herringbone.

This is because there are two of most things including vacuum and milk pumps, receiver jars, pulsation control and two sets of exit gates.

It would have been possible to construct the parlour with some of these shared, eg a vacuum pump and pulsation control unit, but Tom said that if they opted for two of everything if one item was to break down, at least one parlour can continue to operate.

System

At the moment, there are 470 cows going through the parlour and it is taking about one hour and 20 minutes to milk in the morning.

The herd is kept in one group and as the cows in the collecting yard move towards the parlour, they decide what side they want to go into.

In most herringbones, cows have two choices – to either go in the left or right side. In this setup, they have four choices as there are four rows for cows.

There is no backing gate in the rectangular collecting yard but the cows were being fed 1kg of meal in the parlour, morning and evening, and this was probably helping with the excellent cow flow in.

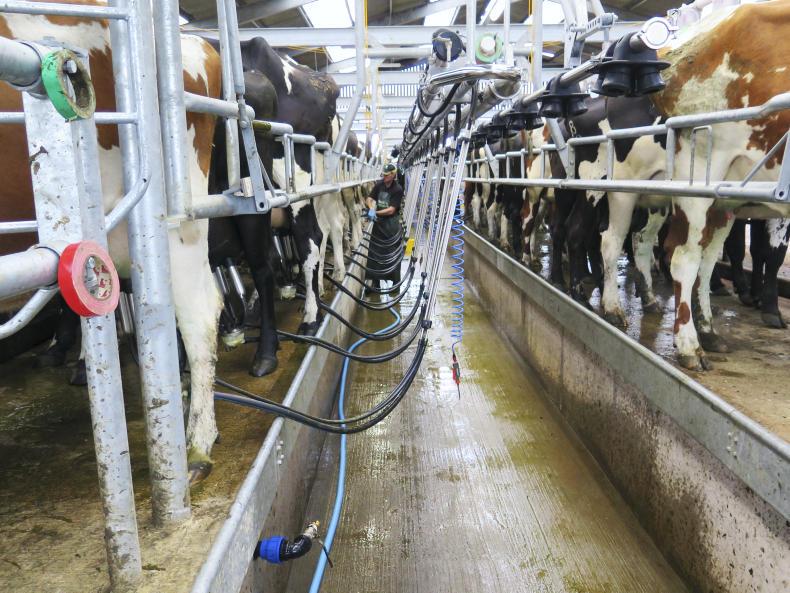

Evening milking was in progress when I visited the farm. The parlour itself is a very basic 24-unit Waikato. There are no swingover arms or automatic cluster removers or milk meters.

The cluster units are attached to an overhead wash-line for when the machine is washing. Both units are identical.

Cows exit through scissor gates, which can be operated from anywhere in the pit.

A pendulum-type bar is installed at the back to keep the last cows in but this wasn’t being used at all. As the cows exited, the scissor gates were closed just as the last cow walked out.

From there, all cows turn left and walk out through the handling unit. There is a manual drafting here that will divert cows to a batch crush and a foot paring crush.

Cows that aren’t drafted are directed down the standard crush, through a footbath and back to the field.

Milk is pumped from the receiver jars into the newly built dairy to the right of the milking shed.

The two milk lines are merged after they go through the milk filter and before they go through the industrial plate cooler and into the bulk tank.

Costs

According to Evolution director Charlie Crotty, the total cost of the milking facilities; plant, dairy building, bulk tank, electrical fittings, wiring, plumbing, handling unit, collecting yard and all associated concrete came to £400,000 (€448,000). Of this, the Waikato milking plant cost £110,000 (€123,000).

In terms of throughput, milking 470 cows in one hour and 20 minutes is impressive. Most rotary parlours of similar-size milking units operate at around 300 cows/hr, but the big difference is that most rotary parlours can be operated by one person.

When comparing parlours, it’s not cows per hour that is the best measure, it is cows per operator per hour that is a better comparison.

The only real advantage of having two parlours side by side is that if one breaks down the other one keeps going.

One person can still operate a large herringbone by leaving clusters hanging up and only using 20 or 24 units.

In terms of cost, the difference in cost between the rotary parlour on page 48 and this parlour is small, but this parlour needs two operators.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: