It’s basic enough, but it is a very functional shed,” according to Paul Groarke, who has just completed building a three-bay suckler shed on his farm near Loughglinn, Co Roscommon. It was completed just in time for winter housing. “I could probably have done with it about a week earlier, but it’s finished now and cattle are housed.”

Paul runs a suckler herd on his farm and needed the extra accommodation to ensure all stock were housed for the winter. “The way that the weather is going, you have to have somewhere for cattle for the winter. It’s just gone too bad.”

It is something that had been in the pipeline for a while, but the decision was made to finally take the plunge, with the help of TAMS II grant aid.

“We first started getting drawings done up nearly two years ago, in January 2016. It can be a slow process,” said Paul.

Planning permission was submitted for the project and was expected to be approved after two months. However, Paul got a letter after two months asking for a nutrient management plan for the farm, which was readily available.

Once this was forwarded to the county council, it took an additional two months before planning permission was granted.

“It was the TAMS grant application which really took the time and effort,” according to Paul. “We were nearly four months sending in designs and adaptations before we got approval to go ahead with the project.

“You really need to give yourself a year (to plan) before you start any of the building work. The bureaucracy of the whole process can hold everything up,” said Paul, frustrated with how long a project can be delayed due to the paperwork.

The building work began in late June 2017, with cows housed in mid-November.

Design details

The shed itself measures 14.4m long by 8.9m wide, not including the overhang of the shed. In an ideal scenario, Paul would have liked to join the new shed to the existing slatted shed. While this is allowed under certain conditions through TAMS, the existing shed did not comply.

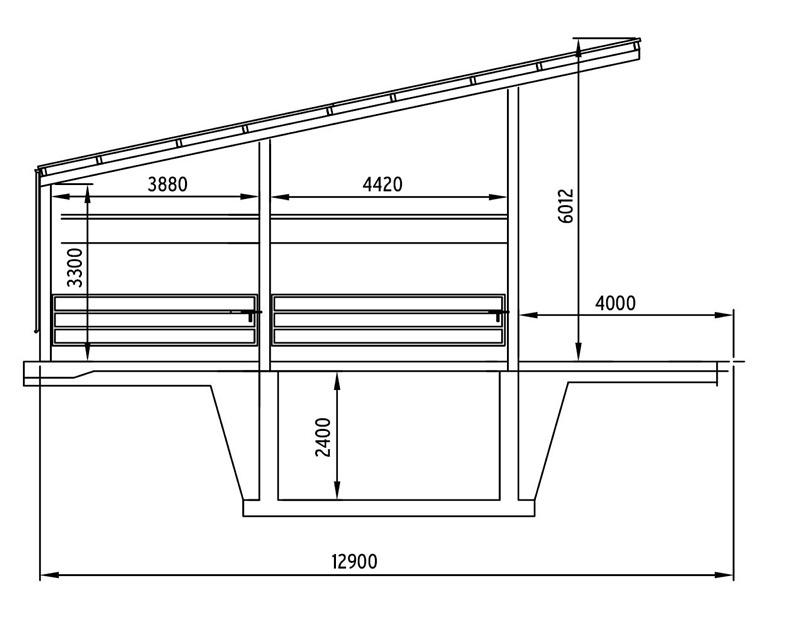

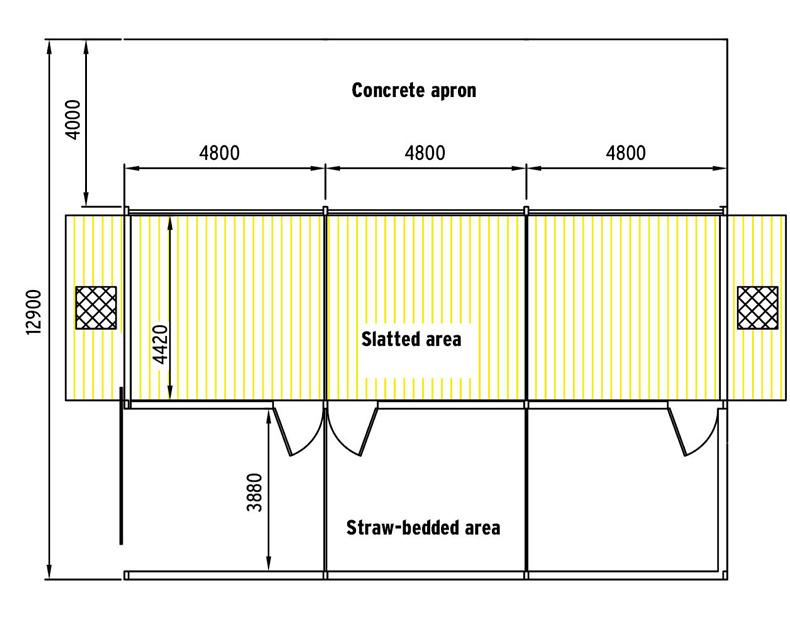

The shed is made up of three 4.8m by 4.2m slatted pens, with three large 4.8m by 3.8m creep pens. Long tractor slats (14ft 6in) were used over the 2.4m deep slatted tank, which is fitted with two external agitation points.

The shed stands at a height of slightly over 6m at its apex and 3.3m at the eaves. A 4m feeding passage has been left between the existing slatted shed and the feeding barrier of the new shed.

A large creep area was installed, as the possibility of changing to organic is something which Paul could see happening in the future.

“If we were to ever go organic, we could very easily provide a straw layback area in this shed. It just gives us more options for the future,” Paul said.

The three creep pens are fitted with water drinkers also. A calving gate is yet to be installed in the creep area, which is accessed through one sliding door.

The large creep also provides the option to feed cattle at the back of the pens. Locking barriers are fitted at the rear of pens, which may be used when it comes to artificially inseminating or dosing cattle.

The rear of the shed was fitted with vented sheeting. Five roof lights were installed on the shed, all of which were fitted with safety bars underneath.

Cost

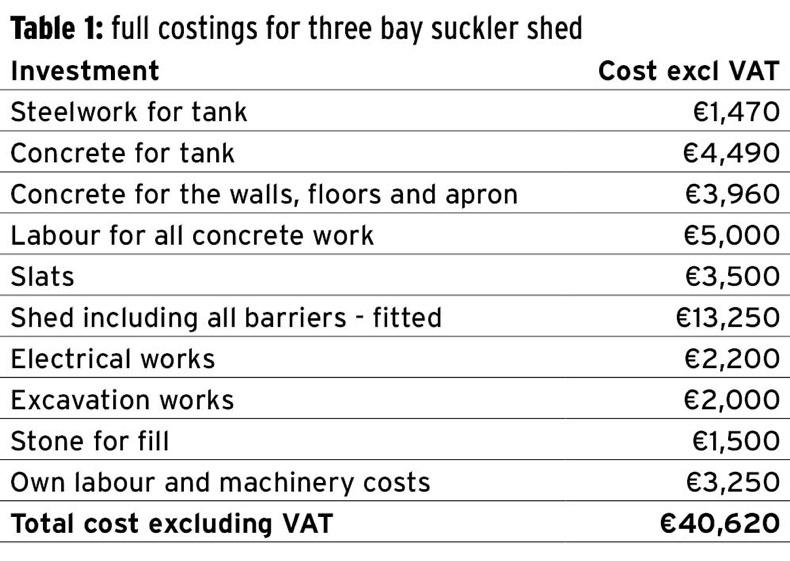

The project came to a total cost of approximately €40,600 excluding VAT, which can be claimed back. A full breakdown of the costs can be seen in Table 1.

As the project was completed through TAMS II, Paul is hopeful of receiving over €16,000 in grant aid (40%). This would leave the shed costing approximately €24,600. Paul aims to submit his TAMS II payment claim before the end of the year.

Additional fill was needed for under the creep area of the shed, as a drain had to be piped underground here.

As the girders for the shed are sitting on the walls of the tank, this required the walls to be a minimum of 400mm thick, which also added cost to the project.

It is important that farmers include their own labour when they are completing the payment claim for the project, where they have carried out some of the work themselves.

Direct constructional work by the applicant or applicant’s family member is costed at €12.40/hour, while the use of a farmer’s own machinery must also be factored in. For example if a farmer uses their own tractor during the course of building the shed, they can cost it at €18.90/hour.

Specification changes

In a recent revision of the Department Specification S123, to be eligible for TAMS II grant aid any new sheds where planning permission or declaration of exemption is sought after 6 September 2017, it is mandatory to provide separate access to pens within a shed, ie creep pens. This means that animals must not have to go through an animal pen to enter or leave a pen. This can be achieved via separate doors to or from pens at gable ends and in the outside wall. Alternatively, an access passage to the rear of the pens would also ensure compliance with the updated specifications.

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: