Often, it is possible to utilise existing sheds in a new construction. Making good use of what you already have can help to save costs and bring life to an old structure.

In 2013, James Madigan, Ballyhale, Co Kilkenny, built a new four-bay slatted shed with a calving area. To increase the housing space in this new shed, he built it adjoining an existing hay shed. The hay shed is an old structure, erected in the early 1900s.

The combination of the new slatted area and calving pens with the existing hay shed now works as both an excellent calving and fattening shed for James’s 80-cow suckler herd and their progeny. Using the hay shed in combination with the new construction was key to the development.

James says that the shed was ideally situated in the yard and had a solid frame to work with despite its age, so it made sense for him to try and maximise its uses by building the new shed adjacent.

“The added space is a massive advantage as you can’t have enough cow space when calving,” says James. The pictures of the shed were taken last spring just after calving. The shed has been cleaned out since.

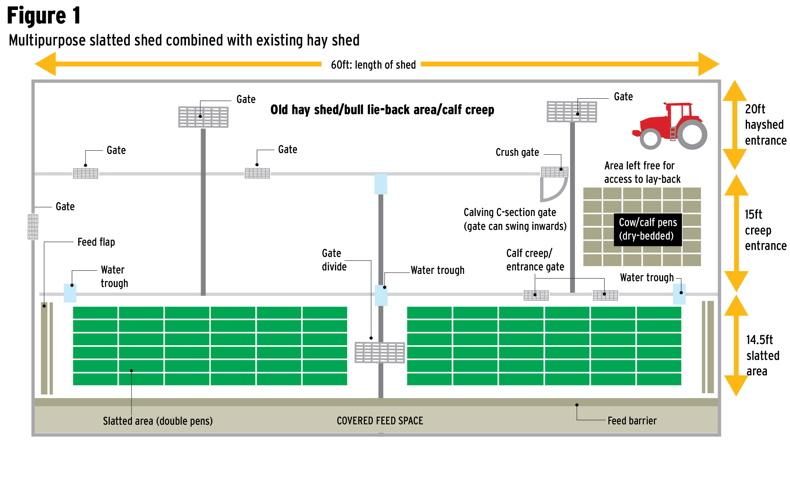

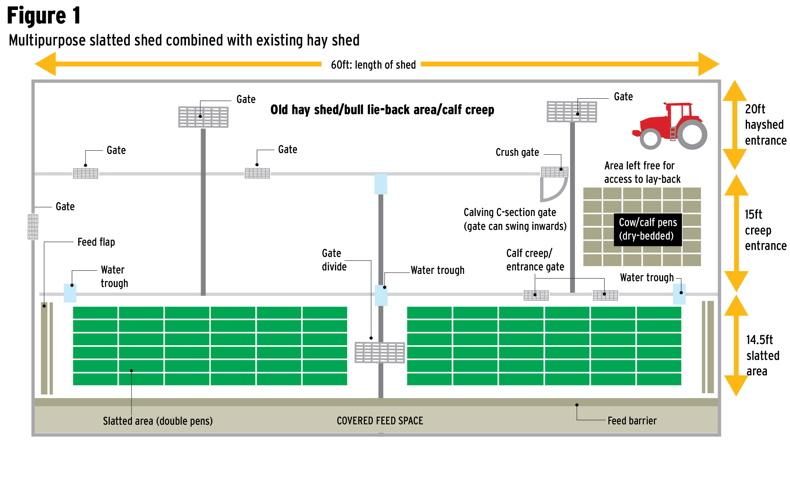

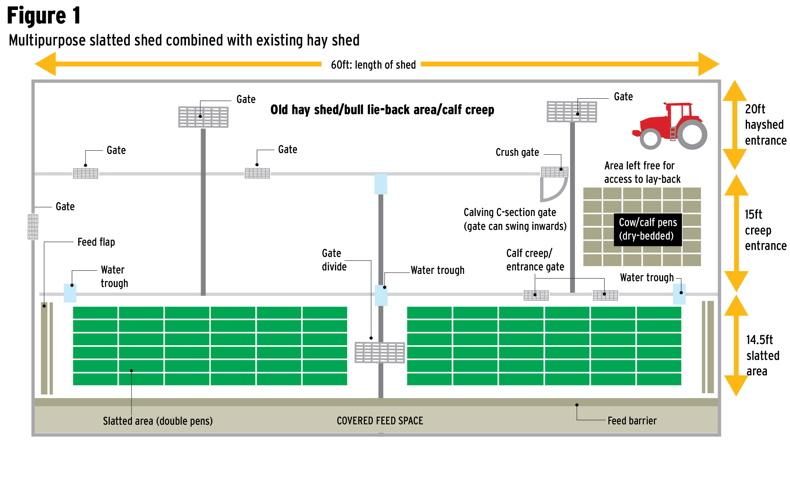

Picture one and figure one

James says he uses the old hay shed now as a lay-back area for the spring-calving herd just before and after calving. Once they calve, depending on udders, he moves them out to the rubber slats and allows only the calves back to a creep area.

The old hayshed is 60ft long and 20ft wide. The creep area is 15ft wide and has an entrance for ease of cleanout. The slatted area is 14.5ft wide. The shed is 16ft high at the eaves and 22ft at the apex.

The new slatted shed and lay-back area were built just in front of the hay shed. In the spring, creep gates give the calves access to the dry bedded area, while cows are held in the slatted area. One pen in the centre of the shed is used for calving. This pen is accessible to both the slatted area and the hay shed lay-back area.

In this pen, there is a C-section calving gate and a head bale. This makes calving time much easier and safer. The shed is also used for finishing bulls. The single calf creep gates are opened out fully, allowing bulls access to the dry bedded lay-back area. This gives bulls more comfort and space, which James finds helps to increase liveweight gain.

Click here to see Figure 1 in PDF format

![]()

Picture two

Here, we see the frame of the old hay shed. Although structurally correct, the galvanised sheeting used to only be attached by hooked bolts (which were popular in hay sheds in the early 1900s), so wooden beams were added to make the sheeting more secure. These, along with the new 5ft concrete walls, have made the structure “sturdier then ever”, according to James.

The opposite end of the shed is facing east and totally open, with the exception of a 10ft gate. This allows for continued cleaning out of the shed over the winter. The shed can still be used for storing hay or straw if needs be.

Picture three

For the new construction, James opted for an A-frame structure, covering both the new slatted tank and calving pens. The front feed passage was left open with ventilated cladding on the west end.

This, combined with the high roof, means that air circulation is optimal. James says that condensation is minimal and he never sees the animals sweating.

Picture four

One of the biggest areas James wanted to develop was suitable calving facilities and a creep area. Three of the four bays have enclosed areas behind the slats (the other bay is not enclosed to allow access to the lay-back area). All of these areas can be used for individual penning of freshly calved cows.

The main pen is fully equipped with a head bale and calving gate from Performance Steel and is also in sight of the calving camera.

James mainly uses the other two pens as the creep area for young calves when mothers are moved to the slats.

Picture five

When finishing bulls, feed space is an issue on many farms. James explains that if he used just two bays, it would only allow him to feed ration to 14 bulls at a time.

As the shed includes a lay-back area, he has plenty of space for 18 bulls. However, due to safety issues, he didn’t want to go down the road of feeding bulls in a trough in the shed. Instead, a simple side-panelled system was designed to increase the feed space in the slatted area. This allows James to place a trough outside the shed and feed the further four animals through the side wall. A permanent trough was considered at first in this area but, due to the location of the tank man-hole cover, something that could be moved easily had to be used.

Picture six

Although the water troughs are metal, James opted to surround them with protection steel. He explains that when dealing with heavy animals, you can’t have enough strength around your troughs. Cattle scratching against the troughs or competing for water is enough to damage them. The steel surround keeps the troughs secure and protects the pipe fittings.

Costs

Overall, the job cost in the region of €70,000, plus VAT.

This wasn’t to grant specification as James wanted to keep costs to a minimum.

A breakdown of some of the costs are as follows. All prices exclude VAT.

Hay barn renovation: €6,000.New A-frame shed: €17,000.Concrete: €24,000.Mats for slats: €6,000.Pens: €7,000.Wiring: €2,500.Excavation work: €5,000.Comment

This shed is a perfect example of how a shed can be designed to fulfil several roles.

A multipurpose shed will always give more flexibility than a plain slatted shed if there are any alterations to the farming system.

The old hay shed now connected with the slatted shed and creep area gives more flexibility for what the shed can be used for. In total, there can be eight individual pens. This may be ideal for farmers who have compact calving herds. In addition to this, it can also be used as a lieback area for bulls on a finishing diet, or individual pens can be used to house stock bulls during the winter.

Gates are important. The strong gates in this shed are built to last and strong enough for housing a stock bull or finishing cattle. The mats, although they are a sizable cost, should have a long life span and are ideal where cows and finishing cattle are to be housed.

Nathan Tuffy

Often, it is possible to utilise existing sheds in a new construction. Making good use of what you already have can help to save costs and bring life to an old structure.

In 2013, James Madigan, Ballyhale, Co Kilkenny, built a new four-bay slatted shed with a calving area. To increase the housing space in this new shed, he built it adjoining an existing hay shed. The hay shed is an old structure, erected in the early 1900s.

The combination of the new slatted area and calving pens with the existing hay shed now works as both an excellent calving and fattening shed for James’s 80-cow suckler herd and their progeny. Using the hay shed in combination with the new construction was key to the development.

James says that the shed was ideally situated in the yard and had a solid frame to work with despite its age, so it made sense for him to try and maximise its uses by building the new shed adjacent.

“The added space is a massive advantage as you can’t have enough cow space when calving,” says James. The pictures of the shed were taken last spring just after calving. The shed has been cleaned out since.

Picture one and figure one

James says he uses the old hay shed now as a lay-back area for the spring-calving herd just before and after calving. Once they calve, depending on udders, he moves them out to the rubber slats and allows only the calves back to a creep area.

The old hayshed is 60ft long and 20ft wide. The creep area is 15ft wide and has an entrance for ease of cleanout. The slatted area is 14.5ft wide. The shed is 16ft high at the eaves and 22ft at the apex.

The new slatted shed and lay-back area were built just in front of the hay shed. In the spring, creep gates give the calves access to the dry bedded area, while cows are held in the slatted area. One pen in the centre of the shed is used for calving. This pen is accessible to both the slatted area and the hay shed lay-back area.

In this pen, there is a C-section calving gate and a head bale. This makes calving time much easier and safer. The shed is also used for finishing bulls. The single calf creep gates are opened out fully, allowing bulls access to the dry bedded lay-back area. This gives bulls more comfort and space, which James finds helps to increase liveweight gain.

Click here to see Figure 1 in PDF format

![]()

Picture two

Here, we see the frame of the old hay shed. Although structurally correct, the galvanised sheeting used to only be attached by hooked bolts (which were popular in hay sheds in the early 1900s), so wooden beams were added to make the sheeting more secure. These, along with the new 5ft concrete walls, have made the structure “sturdier then ever”, according to James.

The opposite end of the shed is facing east and totally open, with the exception of a 10ft gate. This allows for continued cleaning out of the shed over the winter. The shed can still be used for storing hay or straw if needs be.

Picture three

For the new construction, James opted for an A-frame structure, covering both the new slatted tank and calving pens. The front feed passage was left open with ventilated cladding on the west end.

This, combined with the high roof, means that air circulation is optimal. James says that condensation is minimal and he never sees the animals sweating.

Picture four

One of the biggest areas James wanted to develop was suitable calving facilities and a creep area. Three of the four bays have enclosed areas behind the slats (the other bay is not enclosed to allow access to the lay-back area). All of these areas can be used for individual penning of freshly calved cows.

The main pen is fully equipped with a head bale and calving gate from Performance Steel and is also in sight of the calving camera.

James mainly uses the other two pens as the creep area for young calves when mothers are moved to the slats.

Picture five

When finishing bulls, feed space is an issue on many farms. James explains that if he used just two bays, it would only allow him to feed ration to 14 bulls at a time.

As the shed includes a lay-back area, he has plenty of space for 18 bulls. However, due to safety issues, he didn’t want to go down the road of feeding bulls in a trough in the shed. Instead, a simple side-panelled system was designed to increase the feed space in the slatted area. This allows James to place a trough outside the shed and feed the further four animals through the side wall. A permanent trough was considered at first in this area but, due to the location of the tank man-hole cover, something that could be moved easily had to be used.

Picture six

Although the water troughs are metal, James opted to surround them with protection steel. He explains that when dealing with heavy animals, you can’t have enough strength around your troughs. Cattle scratching against the troughs or competing for water is enough to damage them. The steel surround keeps the troughs secure and protects the pipe fittings.

Costs

Overall, the job cost in the region of €70,000, plus VAT.

This wasn’t to grant specification as James wanted to keep costs to a minimum.

A breakdown of some of the costs are as follows. All prices exclude VAT.

Hay barn renovation: €6,000.New A-frame shed: €17,000.Concrete: €24,000.Mats for slats: €6,000.Pens: €7,000.Wiring: €2,500.Excavation work: €5,000.Comment

This shed is a perfect example of how a shed can be designed to fulfil several roles.

A multipurpose shed will always give more flexibility than a plain slatted shed if there are any alterations to the farming system.

The old hay shed now connected with the slatted shed and creep area gives more flexibility for what the shed can be used for. In total, there can be eight individual pens. This may be ideal for farmers who have compact calving herds. In addition to this, it can also be used as a lieback area for bulls on a finishing diet, or individual pens can be used to house stock bulls during the winter.

Gates are important. The strong gates in this shed are built to last and strong enough for housing a stock bull or finishing cattle. The mats, although they are a sizable cost, should have a long life span and are ideal where cows and finishing cattle are to be housed.

Nathan Tuffy

This is a subscriber-only article

This is a subscriber-only article

SHARING OPTIONS: