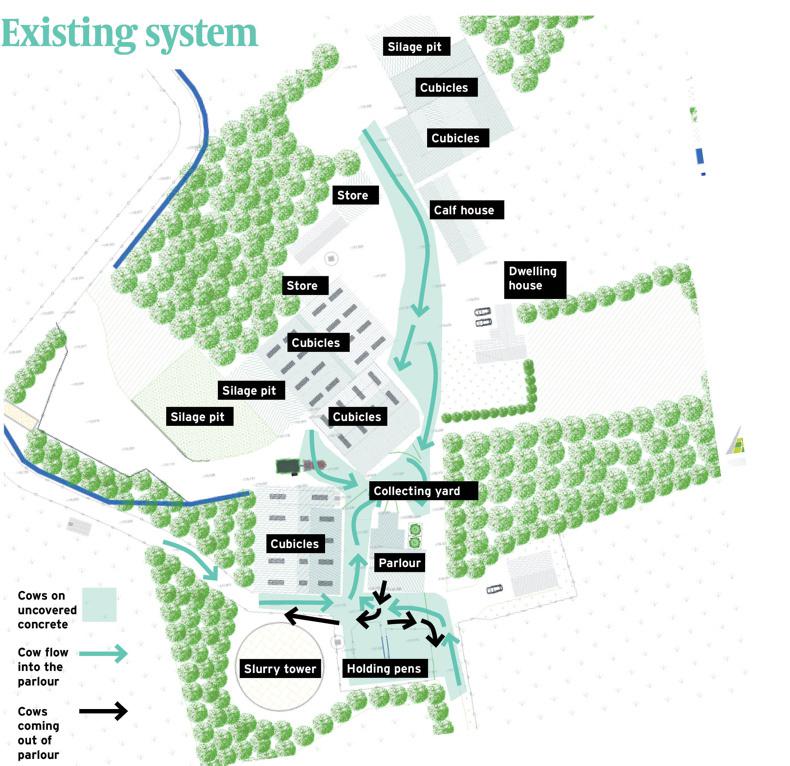

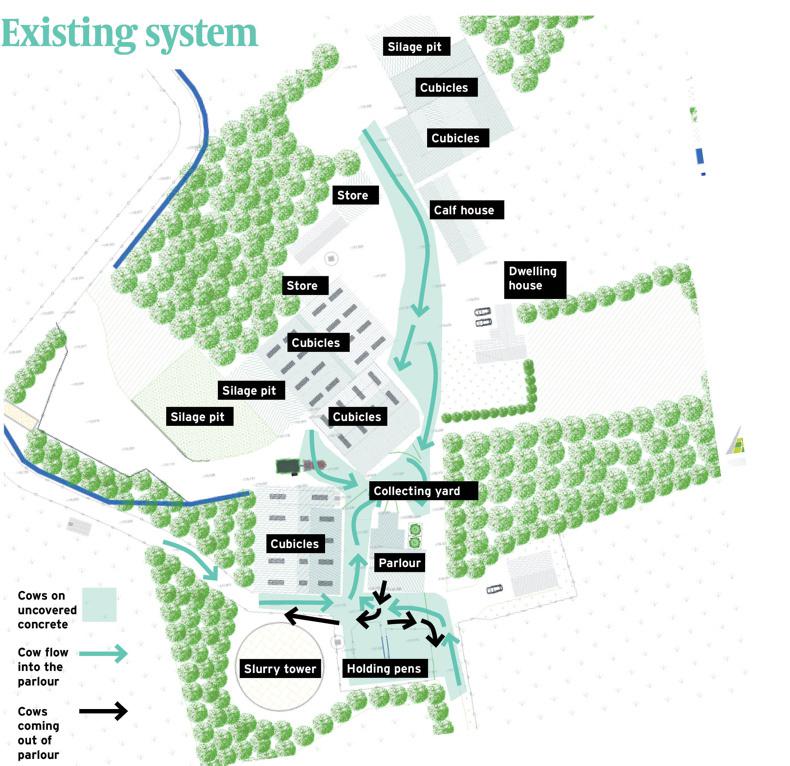

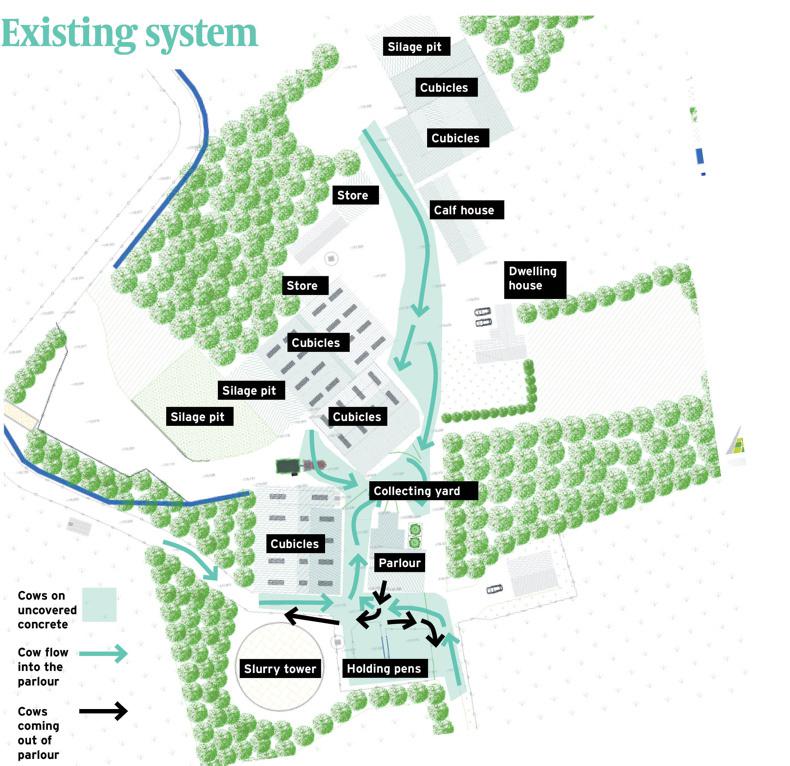

In the existing yard the main issue was that cows were moving throughout the farmyard quite a lot. Even during the summer months when at pasture they would have to enter the yard and make a U-turn before entering the parlour.

Depending on which route they entered the farmyard from, they would have to make one or two 90° turns before they reached the collecting yard. These turns can restrict cow flow and cause a build-up of slurry.

The old collecting yard was positioned in such a way that it would also block up the rest of the yard at milking time. This was not manageable for the increasing herd size so something had to be done. Grasstec surveyed the site and proposed a number of developments which could make best use of the facilities available. These were presented to the farmer, with the chosen design shown.

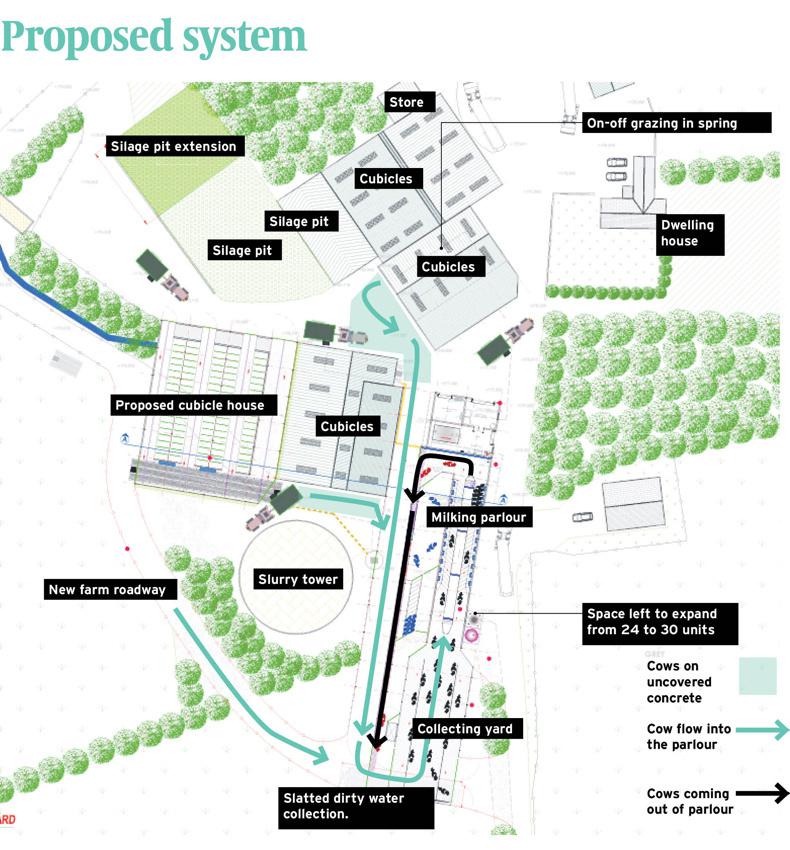

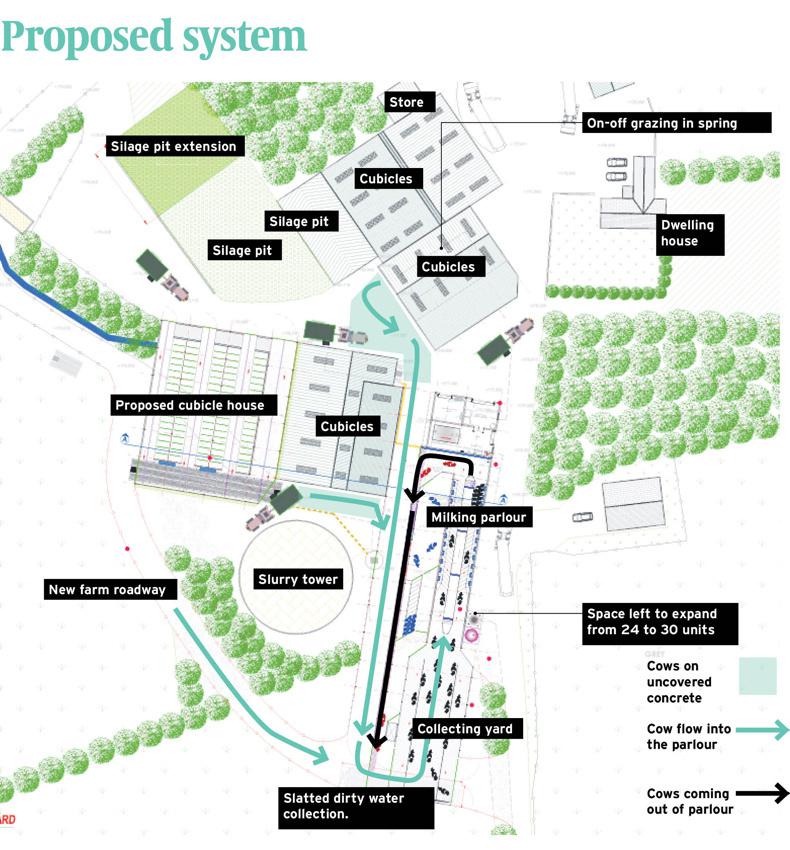

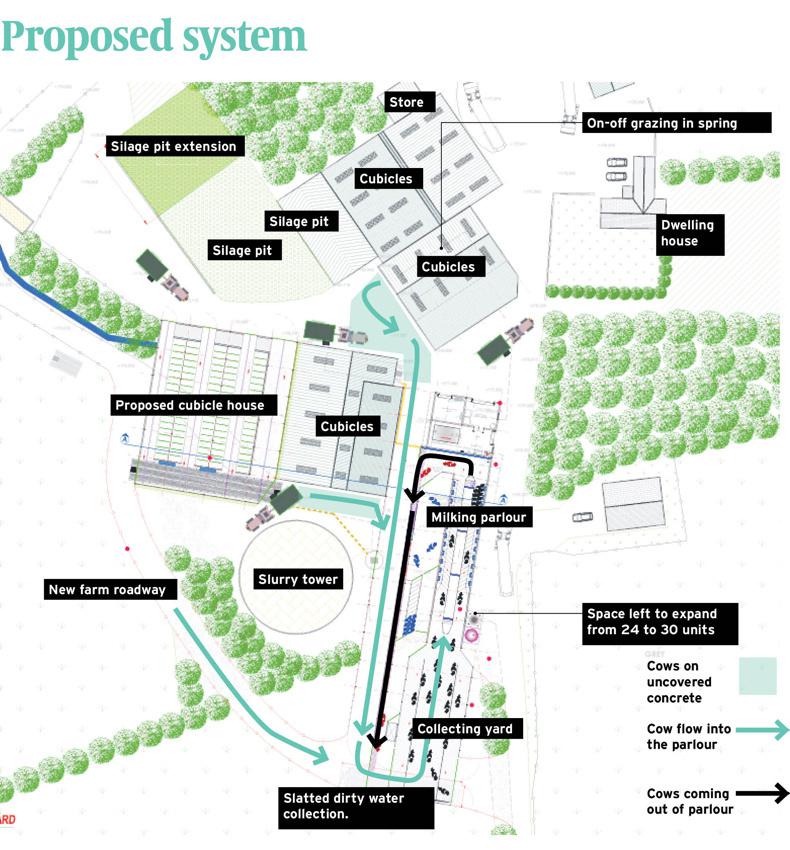

It would see the existing six-unit milking parlour replaced with a 24-unit parlour. There would be space left for this to expand to 30 units, if needed. The existing parlour layout would be mirrored in the new design, with the collection yard brought away from the rest of the yard. This means cows will not be blocking up the yard at milking, allowing milking and feeding, for example, to operate independently of each other.

A major issue with the old design was the amount of time cows spent on uncovered concrete around the yard before and after milking. This increased the amount of soiled water to be collected and the amount of time taken to clean the yard after milking.

In the existing yard the cubicle housing for cows is scattered around the yard. This increases the time taken to gather cows for milking and for carrying out jobs such as buffer feeding.

New design

In the new design the emphasis is on trying to keep the milking herd as close together as possible. When cows are housed for milking, whether at the shoulders of the year or when on/off grazing in spring, the new layout would have most of them in the lower part of the yard. The upper part of the yard can be operated independently, with calves and replacement heifers housed here.

These changes to existing yards have the benefit of reducing the overall labour required on the farm while increasing safety. As herd sizes increase and more than one labour unit becomes common on farms, the benefit of keeping milking independent of the general running of the farm, such as feeding, ensures labour can work efficiently.

All of these design aspects help to reduce the amount of slurry that is produced and the amount of time that it takes to clean the yard after milking.

The cubicle shed next to the milking parlour will be incorporated into the new design, with a new 95-bed cubicle shed adjoining it, as seen in the plans. This six-span A-roofed shed will be fitted with four automatic scrapers that will scrape into a 234m3 tank.

A new roadway will be constructed for cows coming in from pasture. It will bring cows out around the slurry tower and into the back of the new collecting yard without having to access the main yard.

Minimising restrictions while maintaining a good roadway surface is a good way to encourage cows to keep moving to the collecting yard. Large sweeping bends as opposed to sharp turns will also aid cow flow. New farm roadways should be made up of 200-300mm of hard core plus 50-77mm of fine material, with Teagasc estimating that a good roadway can cost between €18 and €30/metre depending on the cost of the materials.

Collecting yard

The rectangular collecting yard is perfectly set up to improve cow flow into the parlour as cows have a straight entrance to the parlour.

This a major upgrade to the existing setup, where cows had to move up a step to enter the parlour. As cows enter from the back it will also help to preserve their social order for milking.

The collecting yard has the capacity to hold 200 cows, with each cow having 1.5m2 of space. The advantage of a rectangular yard means that it can be easily extended in the future if the herd expands further. An automatic scrapper backing gate in the collecting yard pushes slurry down towards a 170m3 slatted tank at the end of the collecting yard.

Approximately half of the collecting yard will be roofed as part of the overall design.

The machinery/livestock passage to the side of the parlour will also be roofed.

This means cows entering the collecting yard from the sheds will not have to walk on exposed concrete, reducing the collection of dirty water.

A long narrow tank is in place along the length of the milking parlour for when cows exit. They will walk on this from when they exit the parlour until they get back on to the farm roadway. Cows can also be drafted when they exit the parlour to a holding pen which has a 12-cow crush and a 13-cow AI crush.

All of these design aspects help to reduce the amount of slurry that is produced and the amount of time that it takes to clean the yard after milking.

It would obviously be preferable if all cows were coming from the one cubicle shed when being milked out of the shed.

However, farmers have to work with the facilities and the farmyards that they have. And in most cases this will involve adapting what you already have. When trying to reduce labour for yourself, addressing the amount of soiled water/slurry you have to collect and improving cow flow should be two priorities.

Read more

Incorporating a new cubicle shed into an existing yard

In pictures: 'the size of the cow is what is killing suckling'

Watch: restoring glory to traditional farm buildings

Watch: safety key for tidy machinery shed

Flexibility key for pedigree breeder

In the existing yard the main issue was that cows were moving throughout the farmyard quite a lot. Even during the summer months when at pasture they would have to enter the yard and make a U-turn before entering the parlour.

Depending on which route they entered the farmyard from, they would have to make one or two 90° turns before they reached the collecting yard. These turns can restrict cow flow and cause a build-up of slurry.

The old collecting yard was positioned in such a way that it would also block up the rest of the yard at milking time. This was not manageable for the increasing herd size so something had to be done. Grasstec surveyed the site and proposed a number of developments which could make best use of the facilities available. These were presented to the farmer, with the chosen design shown.

It would see the existing six-unit milking parlour replaced with a 24-unit parlour. There would be space left for this to expand to 30 units, if needed. The existing parlour layout would be mirrored in the new design, with the collection yard brought away from the rest of the yard. This means cows will not be blocking up the yard at milking, allowing milking and feeding, for example, to operate independently of each other.

A major issue with the old design was the amount of time cows spent on uncovered concrete around the yard before and after milking. This increased the amount of soiled water to be collected and the amount of time taken to clean the yard after milking.

In the existing yard the cubicle housing for cows is scattered around the yard. This increases the time taken to gather cows for milking and for carrying out jobs such as buffer feeding.

New design

In the new design the emphasis is on trying to keep the milking herd as close together as possible. When cows are housed for milking, whether at the shoulders of the year or when on/off grazing in spring, the new layout would have most of them in the lower part of the yard. The upper part of the yard can be operated independently, with calves and replacement heifers housed here.

These changes to existing yards have the benefit of reducing the overall labour required on the farm while increasing safety. As herd sizes increase and more than one labour unit becomes common on farms, the benefit of keeping milking independent of the general running of the farm, such as feeding, ensures labour can work efficiently.

All of these design aspects help to reduce the amount of slurry that is produced and the amount of time that it takes to clean the yard after milking.

The cubicle shed next to the milking parlour will be incorporated into the new design, with a new 95-bed cubicle shed adjoining it, as seen in the plans. This six-span A-roofed shed will be fitted with four automatic scrapers that will scrape into a 234m3 tank.

A new roadway will be constructed for cows coming in from pasture. It will bring cows out around the slurry tower and into the back of the new collecting yard without having to access the main yard.

Minimising restrictions while maintaining a good roadway surface is a good way to encourage cows to keep moving to the collecting yard. Large sweeping bends as opposed to sharp turns will also aid cow flow. New farm roadways should be made up of 200-300mm of hard core plus 50-77mm of fine material, with Teagasc estimating that a good roadway can cost between €18 and €30/metre depending on the cost of the materials.

Collecting yard

The rectangular collecting yard is perfectly set up to improve cow flow into the parlour as cows have a straight entrance to the parlour.

This a major upgrade to the existing setup, where cows had to move up a step to enter the parlour. As cows enter from the back it will also help to preserve their social order for milking.

The collecting yard has the capacity to hold 200 cows, with each cow having 1.5m2 of space. The advantage of a rectangular yard means that it can be easily extended in the future if the herd expands further. An automatic scrapper backing gate in the collecting yard pushes slurry down towards a 170m3 slatted tank at the end of the collecting yard.

Approximately half of the collecting yard will be roofed as part of the overall design.

The machinery/livestock passage to the side of the parlour will also be roofed.

This means cows entering the collecting yard from the sheds will not have to walk on exposed concrete, reducing the collection of dirty water.

A long narrow tank is in place along the length of the milking parlour for when cows exit. They will walk on this from when they exit the parlour until they get back on to the farm roadway. Cows can also be drafted when they exit the parlour to a holding pen which has a 12-cow crush and a 13-cow AI crush.

All of these design aspects help to reduce the amount of slurry that is produced and the amount of time that it takes to clean the yard after milking.

It would obviously be preferable if all cows were coming from the one cubicle shed when being milked out of the shed.

However, farmers have to work with the facilities and the farmyards that they have. And in most cases this will involve adapting what you already have. When trying to reduce labour for yourself, addressing the amount of soiled water/slurry you have to collect and improving cow flow should be two priorities.

Read more

Incorporating a new cubicle shed into an existing yard

In pictures: 'the size of the cow is what is killing suckling'

Watch: restoring glory to traditional farm buildings

Watch: safety key for tidy machinery shed

Flexibility key for pedigree breeder

SHARING OPTIONS