Cubicle housing should ideally provide cows with conditions similar to what they experience while at grass. At grass, animals have space, rest, feed, air, water and light available to them in abundance.

These basics are often taken for granted and it is very seldom that all can be found together in animal housing. We need to observe the natural patterns of dairy cow behaviour and take advantage of this when designing and using facilities.

Too often, these behavioural needs have been ignored or we have just assumed that cows would adapt to the surroundings we provided, instead of providing the surroundings they need.

With so many farms renovating or building new facilities, we need to plan these so that we don’t interfere with the basic needs of the cow, such as resting, feeding and ruminating.

Looking at floor plans of standard designs can help us to tease out various options and find a suitable design and layout for a particular farmyard.

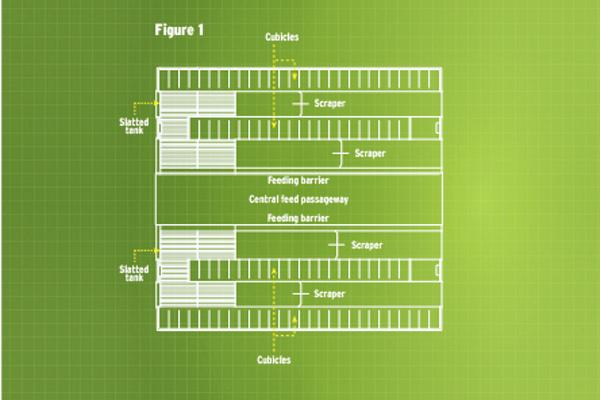

Three of the most common designs are shown in Figures 1, 2 and 3, while Table 1 summarises the various design criteria that have been used with these plans.

A selection of these and other standard drawings are available from your Teagasc adviser. There is also a video on www.teagasc.ie entitled Cubicle Design for Dairy Cows.

Figure 1 is a standard two-row cubicle house design, with two rows of cubicles at either side of a central feed passageway. This is a seven-bay, 100-cow unit, with a double tank across one end. This could also be designed as a single-sided unit with a roof overhang over the feed.

Another layout is to have two double rows of cubicles with a feed barrier under an overhang along each side (no central passageway).

The main advantage of this type of design is that all cows can line up to feed together. Guide costs for the two-row design would be about €1,800 per cow (plus VAT).

Figure 2 is a standard three-row single-sided cubicle house design, with three rows of cubicles parallel to the feed barrier. This is a six-bay, 60-cow unit, with an L-shaped slatted tank.

This could also be designed as a double-sided unit with a central feed passageway and there are options for different tank layouts.

Another layout is to have three double rows of cubicles with a feed barrier under an overhang along each side (no central passageway). This type of design seems to suit the spring calving herds.

The only limitation is feed space, which at about 0.45m/cow, won’t allow all cows to line up together. Guide costs for the three-row design would be about €1,500 per cow (plus VAT).

Figure 3 is a standard drawing of a cubicle house with the cubicles (eight per row) perpendicular to the feed barrier. This is a 48-cow unit, with a single 5m slatted feeding tank along the front.

The limitations of this design are that it’s not really suitable for expansion, the roof design is complicated and managing different group of cows is a bit difficult.

This type of design, with longer lines of cubicles would, typically, need an extra feeding passage along one side in order to provide enough feed space.

Guide costs for this type of design are costly at about €1,800 per cow (plus VAT).

Conversions

Likewise, standard designs can be used as templates for converting existing buildings. Modifying existing facilities can be costly if too many compromises

or modifications are necessary.

If the condition of existing housing is poor and a lot of modification/demolition is needed, it may be better to think again.

However, if the existing housing is suitably located and can be incorporated nicely into the new developments, then that’s fine.

What you want to achieve is a layout that is conveniently located, designed to meet the needs of the animal, is cost-effective, labour-efficient and safe to work in. Many other aspects need to be considered also, such as slurry stor

age, safe agitation, ventilation and site slopes. The general appearance of the farmyard, the colours and roof shapes are also important.

Animal area

The area per animal varies depending on house design. Irrespective of house type, it is desirable to give enough space to the animal. Cows should have access to a minimum of 6.5m2, and with some house designs over 8m2 is available.

There must be enough space at the crossover points too. Space here will reduce bullying and ensure adequate room for drinking. The crossover point should be the width of three cubicles if there is a drinker. It can be the width of two cubicles if the drinker is elsewhere.

The tendency in the past has been to go for small cubicles, narrow passages, short feed space, few and narrow crossovers and narrow tractor passages. Nowadays, having plenty of space is deemed to be more important. Space allowances for the designs in the drawings are outlined in Table 1.

Lying space

Provide one cubicle space per cow. A cow needs to spend 12 to 14 hours per day lying down resting – she is ruminating for six of these.

Resting is more important for cows in milk than dry cows. Cows that spend only nine hours lying down yield three to five litres less than cows lying down for the 12 to 14 hours. This highlights the importance of comfortable cubicles.

Good occupancy and correct lying times can only be achieved if cows are able to lie down and get up with ease and exhibit natural body movement.

If cubicles are too small, cows will be reluctant to lie down and will not rest for as long as they would like to. Cows need to be able to stretch their necks straight out in order to cud properly.

Their health is likely to suffer also. More lameness is likely because they will be standing for longer, especially if they are standing perched with two legs up and two down in the cubicle space. This posture will weaken the tendons in the back feet over time. The back feet will be on hard concrete and in slurry more often also.

Cubicle design

The size of cubicle beds will vary according to animal size, but for dairy cows, it is recommended that beds against a wall should be 2.6m (8ft 6in) long – this might come as a surprise to many but up to 3m (10ft) is recommended for big cows in some countries.

The cubicles should be about 1.18m (3ft 10in) wide with a 5% slope. Increase the width of cubicles beside end walls and walls at crossover points by 10%.

When deciding on kerb height, allow for the thickness of the cubicle mat. Kerb height should be 150mm to 175mm (6in to 7in).

The length of cubicles face-to-face should be 2.4m (8ft) for each. Each cow in a face-to-face cubicle will be surrounded by five other cows when she is lying down, so it is important that each animal has enough space to breathe in fresh air.

The main issue is that cows must display natural body movement when lying down and getting up. You want to see cows lying straight in the cubicle and standing on all four feet.

Feed space

Feed space and access to feed are important for animal performance. Cows spend five to six hours feeding, in nine to 14 feeds throughout the day. A cow that has to spend longer than this feeding will have a lower intake and less time available for resting.

There are several feed barrier designs and all can work well if installed and adjusted properly.

Many straight-rail barriers on farms are restrictive and need adjustment. Most are never adjusted because the problems have not been identified or noticed. Also, many straight-rail feed barriers are too difficult to adjust and lack fine adjustment. Straight-rail feeding barriers should be easy to adjust.

Adjustment will increase reach, allowing more access to feed. This will increase intake, lessen pressure exerted on the barrier and will mean that less silage will have to be pushed in.

A reach of at least 1m from the stub wall is a reasonable target. Observe stock while feeding to evaluate your setup. If you think changes are necessary, make them to one bay initially to see if it improves things.

Good ventilation

Plenty of fresh air is required for the health and performance of housed livestock. In addition, poor ventilation allows corrosion from dust, gases and condensation to weaken and shorten the life of any building.

Ventilation is influenced mainly by the size of the openings, the roof slope, drift distance and the height difference between inlet and outlet. Building orientation and the effects of surrounding buildings and landscape also have a bearing. On the one hand, you want plenty of fresh air, while on the other hand you want to avoid draughts.

Sizes of inlets and outlets mainly depend on the width of the house. Inlets at eaves equivalent to a clear opening of 450mm, 600mm and 750mm are recommended for house widths of up to 15m, 15m to 24m and over 24m, respectively.

Corresponding outlet sizes are recommended in the roof, usually at the roof apex. Photo 1 shows an effective inlet where a clear opening under a short (600mm) roof overhang allows plenty of fresh air in.

If the side-cladding had been lowered even more, it would have been better. The vented side cladding on its own would not provide enough fresh air in calm conditions.

Water

Enough water should be available at all times in dairy cubicle houses and all animals should have access to water whenever they need it. Most people assume that flow rate is not a problem for housed animals. However, it all depends on the number of troughs/groups and group sizes of animals that are drawing off the system, possibly all at the same time. Lactating cows will demand more water than dry cows and the dryness of the feed will also affect their thirst. Use pipe sizes that will not restrict flow rate.

Use heavy-duty water pipes (at least 19mm bore) to bring water to various animal houses in the farmyard (25mm or more for large units).

Narrow-bore (12mm) water pipes will reduce flow rate due to friction between the water and the inside surface of the pipe. Erring on the high side with pipe sizes will reduce pumping costs and ensure a plentiful supply at all times.

Jets in ballcocks can get blocked or partially blocked, so frequently checking that water is getting to troughs is recommended.

Ensure that water troughs/bowls are secure, have no sharp edges or loose covers and that water pipes aren’t in danger of being pulled loose by animals.

A good standard of installation with no joints buried under concrete is desirable. Water bowls, if used, should be large enough for a cow’s muzzle. If the bowl is installed properly, animals will be able to drink without blocking access to a feed barrier.

Lighting

Good light in a shed is an asset. Both natural and artificial light are required. Good use of daylight is important for safe working conditions and for animal health. Natural light is normally provided by translucent roof sheets. The Department of Agriculture specification for these is S102 and a stronger, non-fragile type is now specified. It is recommended that 12% to 16% of the roof area should have roof light sheets. A good level of artificial light is needed also. Fluorescent lamps are practical for this purpose. A 1.5m, T5-type, twin fluorescent lamp will give good energy-efficient light for about 25m2 of floor area.

Clean windows and roof lights to maximise natural daylight and reduce the dependence on artificial lighting.

SHARING OPTIONS