Bauer developed the original quick coupling used on today’s slurry tankers and irrigation systems. Now the Austrian firm has introduced a new range of slurry separation and spreading equipment that may have appeal on Irish farms.

Bauer has been producing separators for its Green Bedding system and has now developed what it calls the bedding recovery unit (BRU). Both systems use a screw-type separation device to separate the fibrous, undigested material from the liquid slurry.

The slurry is pumped into the separator by a separate pump. The solid material is then used as animal bedding where it can be recycled a number of times.

Ultimately, separators remove dry matter from slurry or other waste liquids, freeing up storage space and making the liquids easier and more consistent to handle.

Bauer says that typical dry matter content in slurry ranges from 20% to 28%, so could in effect free up this amount of liquid storage capacity in slurry tanks. Solids can be stored, spread or re-used as bedding.

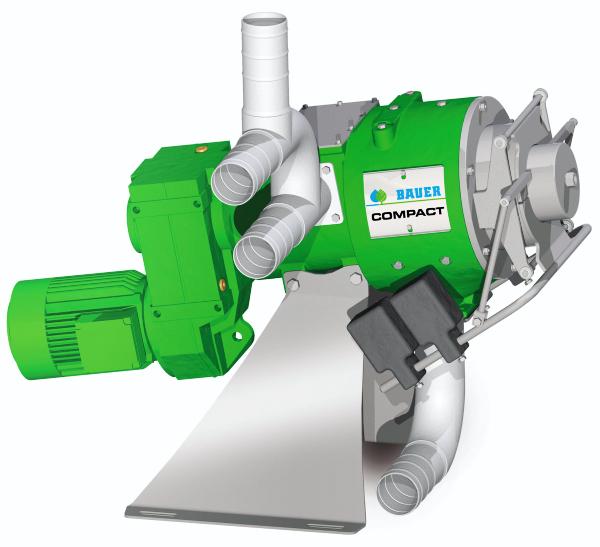

Compact separator

Bauer has developed a new compact separator for smaller dairy and pig farms.

Adrian Tindall, Bauer UK and Ireland sales manager, describes it as a cost-effective option for dairy herds of up to 150 cows. Bauer quotes a typical output of around 5m3/hour for cattle slurry and 7m3 to 10m3/hour for pig slurry.

Slurry is fed into the housing from one side and pushed to the front by the screw, which is driven at just 19rpm by a 3kW (three-phase) electric motor through a reduction gearbox. A continuous plug of fibrous material is formed at the end of the housing where weighted outlet flaps regulate the pressure.

Liquid is extracted through a choice of 0.25mm to 1mm slotted screens and drains to a storage tank or to a sump from where it can be pumped to a dirty water lagoon. The solids fraction is normally stockpiled in a bunker beneath the separator.

The compact separator weighs 420kg and measures 1.3m in length by 0.7m wide and stands 1m high, making it easier to install as part of a waste management system, according to Bauer. It costs around €12,000. Pipes, fixtures and fittings and a control panel will add around €4,200 to the system cost.

Green Bedding

Bauer has installed more than 50 Green Bedding systems in Britain, which use separators to achieve a target of 36% to 38% dry matter of the separated material.

This material can be used to replace cow mats, sawdust or other bedding material in cow cubicle houses.

The company claims to have installed Green Bedding separators on farms with as few as 120 cows. It also claims that there are cost savings from the system by not needing to source bought-in bedding materials.

Adrian Tindall of Bauer claims that producers have experienced either stable or reductions in cell counts with the system. Some users are also reporting a drop in mastitis cases after installing a Green Bedding or BRU system, he claims.

Bauer’s new BRU takes Green Bedding to the next stage. The new BRU Compact unit has been developed for 500-cow herds.

The BRU system takes the material from the Green Bedding system and dries it down to about 42% dry matter. It can then be stored under cover for several days and provides flexibility for very large dairy herds.

The BRU system operates in two stages. Liquid is extracted from the solids contained in farm slurry using one of the heavy-duty, high-throughput screw presses. The liquid is pumped to a storage lagoon for later field application.

Solids are extruded from the separator with a dry matter content of 36% to 38%. These spend about 20 hours passing in a composting drum at 65°C to 70°C. There is no external heat source.

Running costs are limited to the electricity consumed driving the separator and drum and any ancillary equipment, such as a pump.

The active aerobic composting process is claimed to thoroughly dry the material and kill any bacteria that would otherwise multiply during storage. It can then be used in cubicles to provide comfort for high-yielding cows.

All BRU processing equipment is housed in shipping containers. They are delivered ready to be plumbed into the farm’s slurry handling system and three-phase electric power is needed. Daily production is about 12m3 of dried bedding material.

The material is then typically spread using a sawdust spreader or similar to bed the cubicles. Prices start at around €187,000 + VAT for the FAN Compact unit ex-works.

Slurry separation

Bauer has developed a mobile plug-and-play separator, which it claims brings new flexibility to slurry management for large farms. It also opens the way for contractors to provide separation services.

The unit comprises a galvanised steel frame housing a pump and enclosed control panel, with a screw press separator mounted on top with all the necessary pipe work.

Built-in pallet fork slots enable farmers and contractors to quickly offload the unit from a trailer and pack it up again to move to a new location.

According to Adrian Tindall: “It could be an ideal solution for the growing number of farms with more than one dairy unit and slurry storage and handling facilities.

“For contractors, it offers a new service opportunity that will bring the benefits of separation to farms that cannot justify investment in their own system.”

The Bauer plug-and-play unit requires minimal permanent infrastructure. It is available with a choice of Bauer separators to provide different levels of output. It does require a 15kva three-phase electrical supply, fixed or generator.

Contained within the galvanised steel frame are a Bauer screw intake pump and rotary discharge pump, an electronic control unit with cabling and flexible intake, overflow and discharge piping, with Bauer quick coupling for easy connections.

Three versions are available to produce bedding material up to 36% dry matter. Prices are from €51,000. All prices quoted are exclusive of VAT.

Bauer contacts in Ireland

Adrian Tindall, sales manager UK and Ireland. Tel: +447708919597. Email: a.tindall@bauer-at.comTank Storage Systems, Ballyshannon, Co Kildare. Tel: 045-485444. Email: info@tankstoragesystems.comMastek Ltd, Cootehill Business Park, Cornacarrow, Cootehill, Co Cavan. Tel: 049-5555953. Email: enquiries@mastek.ieSub-dealer:

Genesis Distribution, 3 Hammond Road, Upper Ballinderry, Lisburn, BT28 2NG. Tel: +44-787-6452058. Email: stephen@genesisdistribution.co.uk

Bauer developed the original quick coupling used on today’s slurry tankers and irrigation systems. Now the Austrian firm has introduced a new range of slurry separation and spreading equipment that may have appeal on Irish farms.

Bauer has been producing separators for its Green Bedding system and has now developed what it calls the bedding recovery unit (BRU). Both systems use a screw-type separation device to separate the fibrous, undigested material from the liquid slurry.

The slurry is pumped into the separator by a separate pump. The solid material is then used as animal bedding where it can be recycled a number of times.

Ultimately, separators remove dry matter from slurry or other waste liquids, freeing up storage space and making the liquids easier and more consistent to handle.

Bauer says that typical dry matter content in slurry ranges from 20% to 28%, so could in effect free up this amount of liquid storage capacity in slurry tanks. Solids can be stored, spread or re-used as bedding.

Compact separator

Bauer has developed a new compact separator for smaller dairy and pig farms.

Adrian Tindall, Bauer UK and Ireland sales manager, describes it as a cost-effective option for dairy herds of up to 150 cows. Bauer quotes a typical output of around 5m3/hour for cattle slurry and 7m3 to 10m3/hour for pig slurry.

Slurry is fed into the housing from one side and pushed to the front by the screw, which is driven at just 19rpm by a 3kW (three-phase) electric motor through a reduction gearbox. A continuous plug of fibrous material is formed at the end of the housing where weighted outlet flaps regulate the pressure.

Liquid is extracted through a choice of 0.25mm to 1mm slotted screens and drains to a storage tank or to a sump from where it can be pumped to a dirty water lagoon. The solids fraction is normally stockpiled in a bunker beneath the separator.

The compact separator weighs 420kg and measures 1.3m in length by 0.7m wide and stands 1m high, making it easier to install as part of a waste management system, according to Bauer. It costs around €12,000. Pipes, fixtures and fittings and a control panel will add around €4,200 to the system cost.

Green Bedding

Bauer has installed more than 50 Green Bedding systems in Britain, which use separators to achieve a target of 36% to 38% dry matter of the separated material.

This material can be used to replace cow mats, sawdust or other bedding material in cow cubicle houses.

The company claims to have installed Green Bedding separators on farms with as few as 120 cows. It also claims that there are cost savings from the system by not needing to source bought-in bedding materials.

Adrian Tindall of Bauer claims that producers have experienced either stable or reductions in cell counts with the system. Some users are also reporting a drop in mastitis cases after installing a Green Bedding or BRU system, he claims.

Bauer’s new BRU takes Green Bedding to the next stage. The new BRU Compact unit has been developed for 500-cow herds.

The BRU system takes the material from the Green Bedding system and dries it down to about 42% dry matter. It can then be stored under cover for several days and provides flexibility for very large dairy herds.

The BRU system operates in two stages. Liquid is extracted from the solids contained in farm slurry using one of the heavy-duty, high-throughput screw presses. The liquid is pumped to a storage lagoon for later field application.

Solids are extruded from the separator with a dry matter content of 36% to 38%. These spend about 20 hours passing in a composting drum at 65°C to 70°C. There is no external heat source.

Running costs are limited to the electricity consumed driving the separator and drum and any ancillary equipment, such as a pump.

The active aerobic composting process is claimed to thoroughly dry the material and kill any bacteria that would otherwise multiply during storage. It can then be used in cubicles to provide comfort for high-yielding cows.

All BRU processing equipment is housed in shipping containers. They are delivered ready to be plumbed into the farm’s slurry handling system and three-phase electric power is needed. Daily production is about 12m3 of dried bedding material.

The material is then typically spread using a sawdust spreader or similar to bed the cubicles. Prices start at around €187,000 + VAT for the FAN Compact unit ex-works.

Slurry separation

Bauer has developed a mobile plug-and-play separator, which it claims brings new flexibility to slurry management for large farms. It also opens the way for contractors to provide separation services.

The unit comprises a galvanised steel frame housing a pump and enclosed control panel, with a screw press separator mounted on top with all the necessary pipe work.

Built-in pallet fork slots enable farmers and contractors to quickly offload the unit from a trailer and pack it up again to move to a new location.

According to Adrian Tindall: “It could be an ideal solution for the growing number of farms with more than one dairy unit and slurry storage and handling facilities.

“For contractors, it offers a new service opportunity that will bring the benefits of separation to farms that cannot justify investment in their own system.”

The Bauer plug-and-play unit requires minimal permanent infrastructure. It is available with a choice of Bauer separators to provide different levels of output. It does require a 15kva three-phase electrical supply, fixed or generator.

Contained within the galvanised steel frame are a Bauer screw intake pump and rotary discharge pump, an electronic control unit with cabling and flexible intake, overflow and discharge piping, with Bauer quick coupling for easy connections.

Three versions are available to produce bedding material up to 36% dry matter. Prices are from €51,000. All prices quoted are exclusive of VAT.

Bauer contacts in Ireland

Adrian Tindall, sales manager UK and Ireland. Tel: +447708919597. Email: a.tindall@bauer-at.comTank Storage Systems, Ballyshannon, Co Kildare. Tel: 045-485444. Email: info@tankstoragesystems.comMastek Ltd, Cootehill Business Park, Cornacarrow, Cootehill, Co Cavan. Tel: 049-5555953. Email: enquiries@mastek.ieSub-dealer:

Genesis Distribution, 3 Hammond Road, Upper Ballinderry, Lisburn, BT28 2NG. Tel: +44-787-6452058. Email: stephen@genesisdistribution.co.uk

SHARING OPTIONS