Ken Graham Engineering Ltd is a name that is synonymous with combine parts and accessories for the past five decades. Developing its first concave in 1968, the family-owned business has constantly been looking at ways for farmers to get more from their machines.

According to David Graham from the family engineering company, the high-output concaves have been a huge success all across Europe and in particular France and the UK. David added that the new Maxi Threshing kit concept has already been shortlisted by the International Machinery Manufacturers Association (IMMA), with the firm now down to the last two for an award at this year’s Cereals 2016 event.

How does it work?

After years of carrying out repairs on combines, David and his father Ken, who founded the business, noticed that all of the wear was mostly on the centre of the concave and rasp bars. It was clear to see that the outside of the rasp, approximately 6in each side of the separating drum, was giving 12in of unused area in the separating drum. The Grahams say this is approximately the width of one straw walker unused.

So in essence this unit could increase the output of a five-walker combine to nearer that of a six-walker machine, according to David.

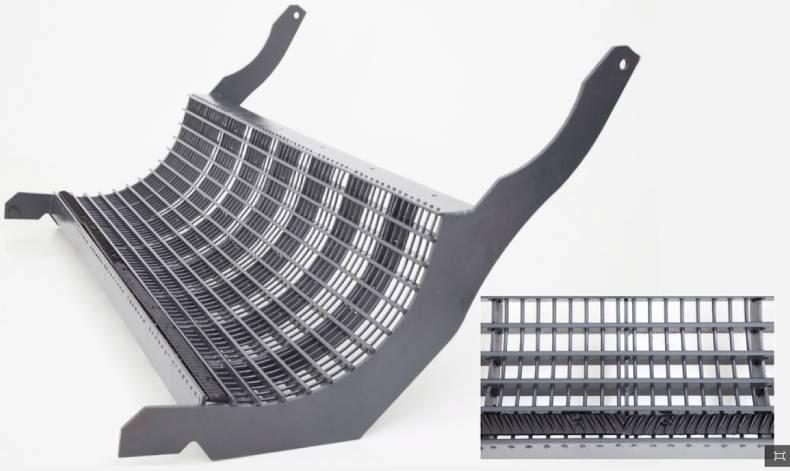

The new Maxi Threshing Kit works off the principle of deflecting the incoming crop from the neck chain over the entire working width of the concave. The unit eliminates the crop pushing into the middle of the drum.

David believes that this will increase the threshing performance of any combine by about 15%. He says it makes total sense when you examine the crop flow that this unit will benefit the harvesting of all crops.

This is especially so in heavy winter crops, as the advancements in disease control make the straw often greener and harder to thresh out the grain. Most combines we examined were only using about 85% of the concave’s threshing capacity. With this unit fitted, 100% of the concave is utilised.

Spreading the intake over the working width should in theory reduce downtime with blockages and also allow for increased performance in poorer weather conditions. “The combine harvester benefits by being able to have a faster ground speed and produce a cleaner crop sample,” says Ken.

Fitting the unit

The Maxi-Threshing kit is very easy to install. The deflector stripper bars are bolted to the front of the concave. They are mainly designed to work in high-output concaves, but can fit into all makes and models of combine harvester, even with standard concaves. The big plus, according to David, is that the unit is fitted without removing the concave and only takes about 20 minutes to install.

David said the five-walker kit costs €195 plus VAT, while the six-walker kit costs €235 plus VAT. This a lot less than upgrading to a bigger machine, added David. The product will be officially launched in the UK at the Cereals event this year.

SHARING OPTIONS