There’s been a lot of talk of late about strong calf prices come spring 2026 and the possibility of a further slippage in milk prices leading to farmers investing more time and money into calves to maximise their return to offset milk price somewhat.

As a general rule, calves are also staying on farms longer; beef farmers want stronger calves, as do exporters, while the ever-looming threat of TB means more dairy farmers are investing in calf facilities to future proof themselves to be able to hold the majority of calves born on farm up to weaning.

We have featured plenty of new calf sheds in the buildings pages of the Farmers Journal featuring automatic feeders as part of these investments.

One thing often cited to me regarding these feeders is that, while they are a labour saving during the peak spring period, a lot of ‘waste’ milk (milk from second and third milkings, high SCC milk) is utilised in feeding whole milk but would be dumped in the case of all calves being on an automatic feeder.

JFC have developed an extra to their Evolution S4 unit – the Pro+ – which allows for either milk powder and/or whole milk to be fed through the unit.

Replacement heifer calves on the JFC Evolution S4 Pro+ unit drinking milk replacer.

Declan O’Donnell, Evolution sales manager with JFC, talked us through one of the units fitted on a large Meath dairy farm in late 2024.

With the herd calving down 1,200 cows between a split spring and autumn calving pattern, the unit is now on its third set of calves.

Declan explained: ‘’We have a lot of these units sold here in Ireland and further afield in export markets where whole milk is more commonly fed than powdered milk.”

The unit works in a similar way to the original S4 unit with regard to milk powder; the hopper on top of the machine is filled with powder and feed through the auger to the mixing bowl, with the allocation of powder being correlated to the curve set by the farmer ie calves are built up incrementally to their max feeding level (usually at age three-four weeks) before the volume of powder is reduced ahead of weaning for a stress-free weaning and easy transition on to their solid diet.

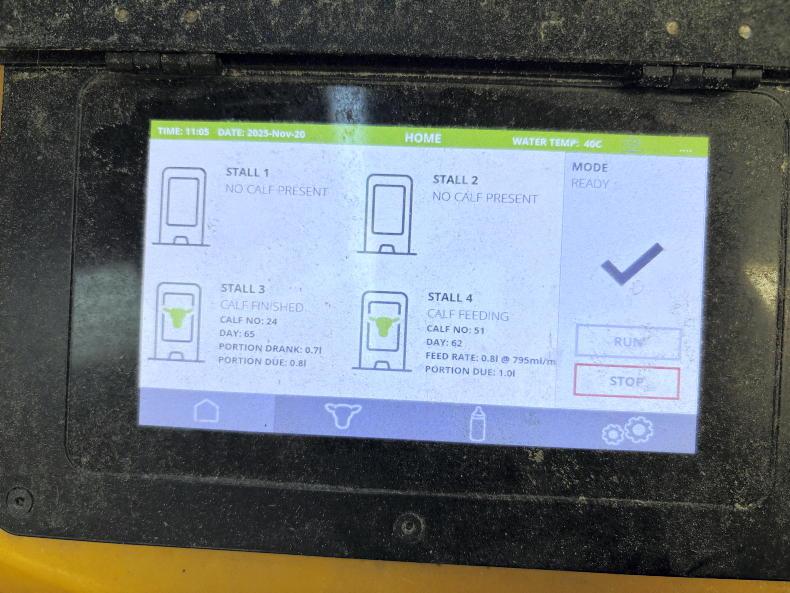

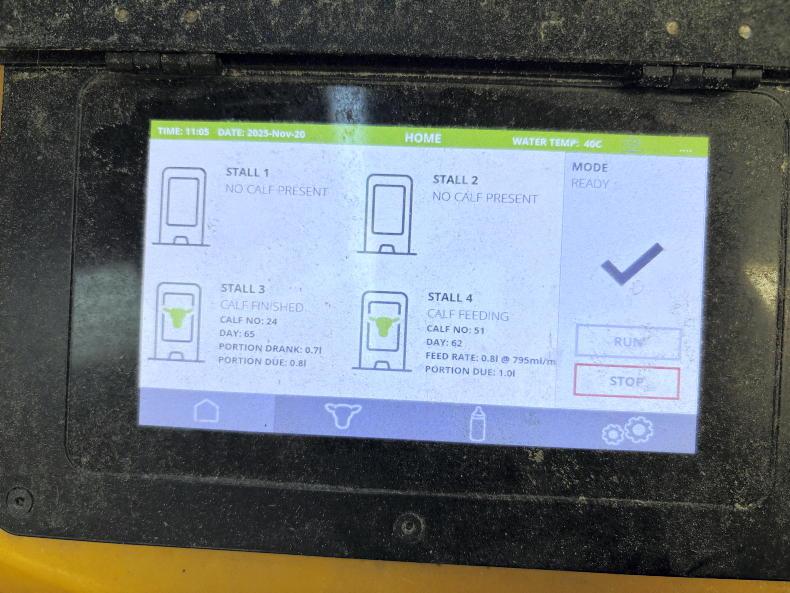

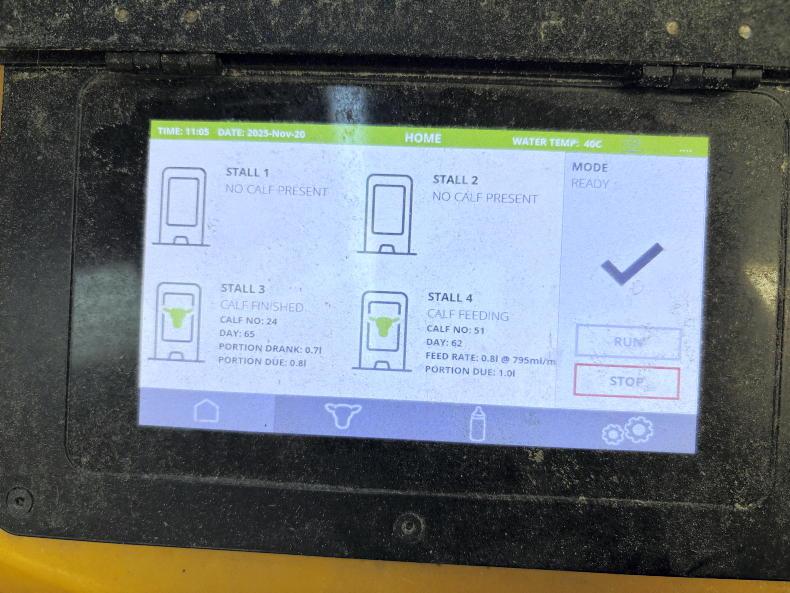

As seen, in stall 3 calves are drinking whole milk measured in litres, while calves in stall 4 are drinking powdered milk at a set rate.

In a similar manner, calves on whole milk are built up to their peak intake in litres as opposed to grams, before their allocation is reduced. Whole milk is stored in a cooled buffer tank (usually circa 500 litres) and fed through to the S4 unit, where it enters the mixing bowl in the same way as water does for the powder. ‘’500 litres is probably the best size for many farms operating this unit,’’ stated Declan.

‘’You want to be keeping milk fresh, ideally topping the tank up each day with little of yesterday’s milk in it. The farmer here cleans out the bulk tank fully once a week, similar to how you would clean out your normal bulk tank.’’

Mixing milk powder

and whole milk

For the farmer in question, and many others, there won’t be a constant supply of waste milk on farm, especially in spring when there can be more cows calving one week than the other. Currently, the farm is utilising waste milk from the herd combined with powdered milk as required.

If required, the farmer will top p whole milk with some milk replacer in the milk cart and then transport it to the buffer tank.

The powdered milk is being mixed in the towable milk kart and topped up with whole waste milk, the pump on the milk kart then transferring over the milk into the cooled bulk tank.

‘’We are currently looking at a way of setting the machine so that it will be able to combine milk powder and whole milk by itself, in that you would be able to set it that 60% of the calf’s feed is whole milk and is then topped up with 40% powdered milk, for example,’’ noted Declan.

No digestive upsets are recorded by the farmer in question. Calves are transferred on to the unit from the calving box, meaning that they aren’t accustomed to a bucket feeder and are easily trained.

The feeder was installed in a former milking parlour, which is working well health wise and making good use of the building.

One issue came about with using first or seconds colostrum from cows, in that the constituents and composition of this milk was unsuitable for feeding. A recalibration on the side using whole milk and the use of second milkings or after milk being used via the machine rectified this.

On a cost point of view, the addition of the PRO+ whole milk feature to the S4 unit is in the region of €4,000-4,500, while the 500 litre refrigerated tank new will tack on another €6,000 to the bill. Where a farmer has a smaller tank themselves as a buffer tank, this can be plumbed in to the S4 unit. JFC would recommend that all tanks are refrigerated.

Beef calves are reared with whole milk and topped up with milk replacer when supplies are low.

Integration into

existing building

The farmer in question has integrated the system into an older building that, in a previous life, was used as a parlour and collecting yard.

The area closes to the door is primarily slatted, while a line of slats can also be seen running lengthways through the feed passage in the middle; this was where the pit of the parlour was.

The first thing that was done when converting the shed over was to remove the ridge capping in the middle, leaving this fully open to act as an air outlet.

The volume of milk dispensed is measured through the metered nozzle of the milk cart.

Two bays towards the front of the shed are not attached to an adjoining shed, but the remainder of the shed is on both sides, which made air inlet spacing tricky.

Sheeting was removed at the rear of the shed to increase air inlet room and on the day of our visit the air was cool and clean without any draughts present.

I like the system a lot.

With more talk of poor milk price and farmers feeding whole milk to calves, it could be a useful addition to farms.

Saying this, it will be more for a farmer that plans on feeding whole milk up to weaning of a beef/ replacement calves at this cost; it wouldn’t be financially justifiable for people feeding whole milk for just the first two weeks or so.

What will be an even simpler system is when they design the unit to combine whole milk with milk powder without the farmer having to mix the powder themselves.

The farmer in question is extremely happy with the system, and like many farmers who I have visited with automatic calf feeders, they would not revert back to manual feeding.

The farmer in question has integrated the system in to an older building that in a previous life was used as a parlour and collecting yard.

The area closest to the door is primarily slatted, while a line of slats can also be seen running length ways through the feed passage in the middle; this was where the pit of the parlour was.

The first thing that was done when converting the shed over was to remove the ridge capping in the middle, leaving this fully open to act as an air outlet.

Two bays towards the front of the shed are not attached to an adjoining shed, but the remainder of the shed is on both sides, which made air inlet spacing tricky.

Sheeting was removed at the rear of the shed to increase air inlet room and on the day of our visit the air was cool and clean without any draughts present.

There’s been a lot of talk of late about strong calf prices come spring 2026 and the possibility of a further slippage in milk prices leading to farmers investing more time and money into calves to maximise their return to offset milk price somewhat.

As a general rule, calves are also staying on farms longer; beef farmers want stronger calves, as do exporters, while the ever-looming threat of TB means more dairy farmers are investing in calf facilities to future proof themselves to be able to hold the majority of calves born on farm up to weaning.

We have featured plenty of new calf sheds in the buildings pages of the Farmers Journal featuring automatic feeders as part of these investments.

One thing often cited to me regarding these feeders is that, while they are a labour saving during the peak spring period, a lot of ‘waste’ milk (milk from second and third milkings, high SCC milk) is utilised in feeding whole milk but would be dumped in the case of all calves being on an automatic feeder.

JFC have developed an extra to their Evolution S4 unit – the Pro+ – which allows for either milk powder and/or whole milk to be fed through the unit.

Replacement heifer calves on the JFC Evolution S4 Pro+ unit drinking milk replacer.

Declan O’Donnell, Evolution sales manager with JFC, talked us through one of the units fitted on a large Meath dairy farm in late 2024.

With the herd calving down 1,200 cows between a split spring and autumn calving pattern, the unit is now on its third set of calves.

Declan explained: ‘’We have a lot of these units sold here in Ireland and further afield in export markets where whole milk is more commonly fed than powdered milk.”

The unit works in a similar way to the original S4 unit with regard to milk powder; the hopper on top of the machine is filled with powder and feed through the auger to the mixing bowl, with the allocation of powder being correlated to the curve set by the farmer ie calves are built up incrementally to their max feeding level (usually at age three-four weeks) before the volume of powder is reduced ahead of weaning for a stress-free weaning and easy transition on to their solid diet.

As seen, in stall 3 calves are drinking whole milk measured in litres, while calves in stall 4 are drinking powdered milk at a set rate.

In a similar manner, calves on whole milk are built up to their peak intake in litres as opposed to grams, before their allocation is reduced. Whole milk is stored in a cooled buffer tank (usually circa 500 litres) and fed through to the S4 unit, where it enters the mixing bowl in the same way as water does for the powder. ‘’500 litres is probably the best size for many farms operating this unit,’’ stated Declan.

‘’You want to be keeping milk fresh, ideally topping the tank up each day with little of yesterday’s milk in it. The farmer here cleans out the bulk tank fully once a week, similar to how you would clean out your normal bulk tank.’’

Mixing milk powder

and whole milk

For the farmer in question, and many others, there won’t be a constant supply of waste milk on farm, especially in spring when there can be more cows calving one week than the other. Currently, the farm is utilising waste milk from the herd combined with powdered milk as required.

If required, the farmer will top p whole milk with some milk replacer in the milk cart and then transport it to the buffer tank.

The powdered milk is being mixed in the towable milk kart and topped up with whole waste milk, the pump on the milk kart then transferring over the milk into the cooled bulk tank.

‘’We are currently looking at a way of setting the machine so that it will be able to combine milk powder and whole milk by itself, in that you would be able to set it that 60% of the calf’s feed is whole milk and is then topped up with 40% powdered milk, for example,’’ noted Declan.

No digestive upsets are recorded by the farmer in question. Calves are transferred on to the unit from the calving box, meaning that they aren’t accustomed to a bucket feeder and are easily trained.

The feeder was installed in a former milking parlour, which is working well health wise and making good use of the building.

One issue came about with using first or seconds colostrum from cows, in that the constituents and composition of this milk was unsuitable for feeding. A recalibration on the side using whole milk and the use of second milkings or after milk being used via the machine rectified this.

On a cost point of view, the addition of the PRO+ whole milk feature to the S4 unit is in the region of €4,000-4,500, while the 500 litre refrigerated tank new will tack on another €6,000 to the bill. Where a farmer has a smaller tank themselves as a buffer tank, this can be plumbed in to the S4 unit. JFC would recommend that all tanks are refrigerated.

Beef calves are reared with whole milk and topped up with milk replacer when supplies are low.

Integration into

existing building

The farmer in question has integrated the system into an older building that, in a previous life, was used as a parlour and collecting yard.

The area closes to the door is primarily slatted, while a line of slats can also be seen running lengthways through the feed passage in the middle; this was where the pit of the parlour was.

The first thing that was done when converting the shed over was to remove the ridge capping in the middle, leaving this fully open to act as an air outlet.

The volume of milk dispensed is measured through the metered nozzle of the milk cart.

Two bays towards the front of the shed are not attached to an adjoining shed, but the remainder of the shed is on both sides, which made air inlet spacing tricky.

Sheeting was removed at the rear of the shed to increase air inlet room and on the day of our visit the air was cool and clean without any draughts present.

I like the system a lot.

With more talk of poor milk price and farmers feeding whole milk to calves, it could be a useful addition to farms.

Saying this, it will be more for a farmer that plans on feeding whole milk up to weaning of a beef/ replacement calves at this cost; it wouldn’t be financially justifiable for people feeding whole milk for just the first two weeks or so.

What will be an even simpler system is when they design the unit to combine whole milk with milk powder without the farmer having to mix the powder themselves.

The farmer in question is extremely happy with the system, and like many farmers who I have visited with automatic calf feeders, they would not revert back to manual feeding.

The farmer in question has integrated the system in to an older building that in a previous life was used as a parlour and collecting yard.

The area closest to the door is primarily slatted, while a line of slats can also be seen running length ways through the feed passage in the middle; this was where the pit of the parlour was.

The first thing that was done when converting the shed over was to remove the ridge capping in the middle, leaving this fully open to act as an air outlet.

Two bays towards the front of the shed are not attached to an adjoining shed, but the remainder of the shed is on both sides, which made air inlet spacing tricky.

Sheeting was removed at the rear of the shed to increase air inlet room and on the day of our visit the air was cool and clean without any draughts present.

SHARING OPTIONS