The registration of the new triazole, Revysol, late last year is a welcome introduction to the crop protection scene on these islands. This is because of the continuous weakening of the triazoles, the loss of the strobilurins, the concerns over the SDHIs and the imminent loss of chlorothalonil. Together these issues have worried grain producers for the past number of years.

The instant concern is that this is yet another triazole, and it is, but with a modified structure. This would not normally be enough in today’s climate of evolving biology, but it seems that Revysol is much more than just another triazole. Never before did we have such a handle on a new molecule at the point of its introduction.

There can be little doubt but that our background knowledge continues to increase and new molecules need to be able to tell a big story to appear impressive.

This is not just a big story. It is big in terms of a market need, as other actives are either decreasing in efficacy or being lost. But it is also big in terms of its difference as an azole and its ability to control septoria.

Chlorothalonil use is to cease on 20 May. The consequence of this is the enhanced exposure of weakening SDHI actives to continuously weakening triazoles. So what will yet another azole do?

Fungicide/fungus relationship

One of the major differences that Revysol brings is the ability of the molecule to flex and assume different physical shapes. This is because one component of the molecule, called the isopropanol linker, enables its shape to flex to fit variable shapes.

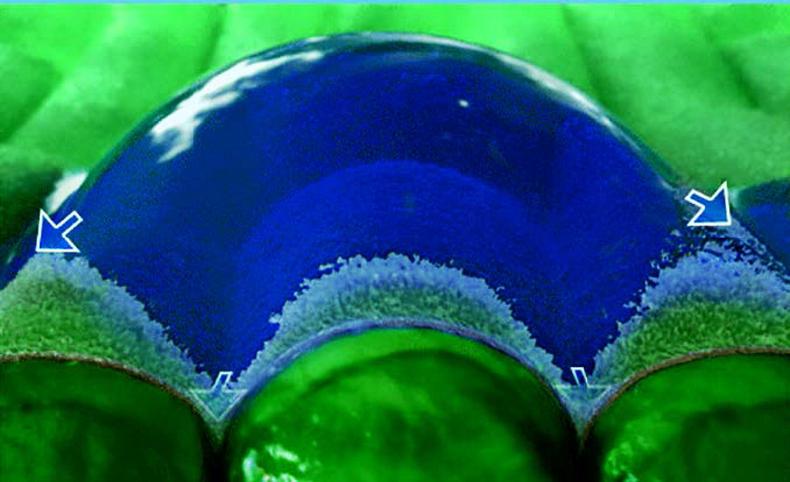

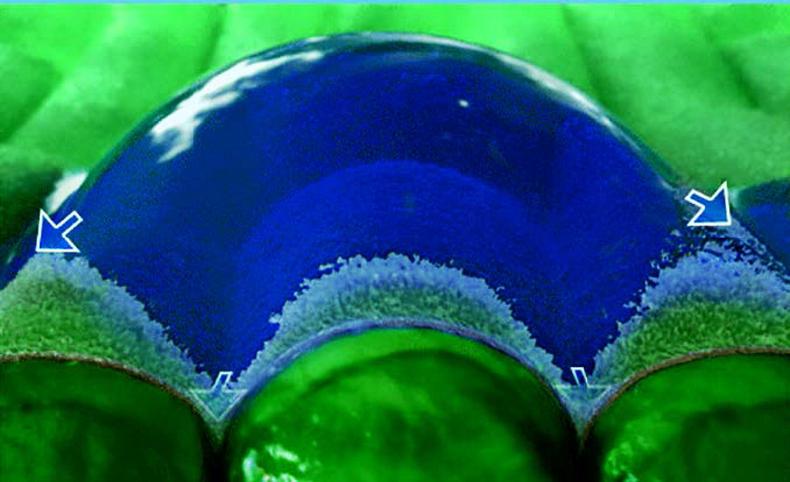

The new azole, Revysol, carries a novel formulation which enables it dissolve in water for application.

Let’s backtrack a little. A fungicide/fungus interaction is often described as a lock and key. When they are an exact fit the fungicide can act to kill the fungus. But if there is a slight alteration in the lock (fungus), the key (fungicide) will no longer work. An equivalent description of the process is a hand and glove comparison – when they fit comfortably together, the fungus can be killed.

Once inside the leaf, Revysol sits just beneath the leaf cuticle and from there it moves very slowly to provide both curative and protectant disease control.

Staying with the glove simile (the fungus), in shape terms it is the ‘thumb’ that is the important bit because that is where the azole component of the molecule fits into the enzyme to prevent it from working and so stop fungus growth. According to BASF, the main reason for decreased triazole sensitivity is an alteration to the positioning of the ‘thumb’ in the target enzyme in the fungus.

If we assume that the original triazoles worked well in the ‘thumbs up’ position, fungicide efficacy would be poor when most of the enzymes had a ‘thumbs out’ or ‘thumbs back’ position. While this simile is solely for description purposes, BASF people say that known mutations which limit azole activity fit this description.

The company says the uniqueness of the isopropanol linker component of the molecule enables it to fit comfortably into known mutation positions and so provide excellent control of all septoria, the mutations and the wild types.

The challenge of keeping wheat crops free of septoria seems feasible again following the introduction of Revysol.

The inevitable follow-on question here is, will the active be able to kill mutations that we are not yet even aware of? According to Steve Dennis of BASF, it seems possible that this unique flexibility, which is referred to as Revysol Flexi-Power, will cope with future enzyme shape-related mutations at this point. Steve said that scientists generally believe that there is a limit to the structural change that can occur in this enzyme and that this molecule can cope with these. It is thought that change in the enzyme beyond which the molecule can achieve is likely to naturally limit the fungus itself.

So the principle here is that the molecule can adapt to the shape of the binding pocket in the enzyme in the fungus. But that is not its only strength.

Binding power

Another stated element of the exceptional performance of Revysol is its binding power once it comes in contact with the enzyme in the fungus. Even where the key fits the lock or the hand fits the glove perfectly, it was suggested that these couplings are actually less permanent than we might have been led to believe in the past. Steve suggests that it was not uncommon for the key or the hand to come out again, possibly because there is a small element of movement in all molecules which may cause them to be displaced.

Whether that be perfectly true or not, BASF claims that Revysol binds to the enzyme on average over 100 times more powerfully than conventional azoles. In saying that, some are better than others, but the benefit seems tangible. This is given as the reason for the very strong fungicidal efficacy exhibited by the compound. It also helps to explain its efficacy despite slow mobility in the plant.

The azole challenge

We in Ireland are very aware of the failing efficacy of azoles against septoria and ramularia in particular. But this is not the only problem that azoles have, as the group has largely become subject to the endocrine disruptor element of the Sustainable Use Directive legislation. This has been a subject of some debate for many years now and so it is a real concern for all azoles and especially for new azoles.

It appears that most azoles are now likely to be revoked due to this inherent characteristic, so endocrine disruption has become a significant obstacle for any new active. To put this in perspective, our fungicides target what is known as the CYP 51 enzyme, which is involved in cell wall formation in the fungus and if there is no cell wall, there is no fungus. This is an ‘on-target’ effect.

While this new active appears quite active and robust, we must still aim to have it applied at the correct timings and be sensible about application rate and how we protect it.

The problem is that the same active can also target the CYP 19 enzyme in the mammalian endocrine system, which is an ‘off-target’ effect. An active with this characteristic can have a potentially hazardous impact on mammalian reproductive systems. So, the challenge for any new azole is to have a big impact on CYP 51 and little or no impact on CYP 19.

This ‘off-target’ effect seems to be mainly related to the structure of that part of the molecule which is not the azole element. BASF says that Revysol manages to optimise its relative impact on these two targets.

Formulation characteristics

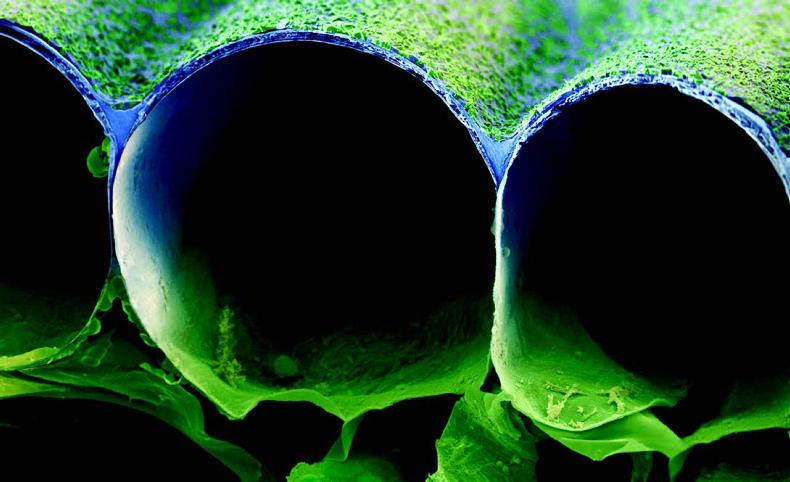

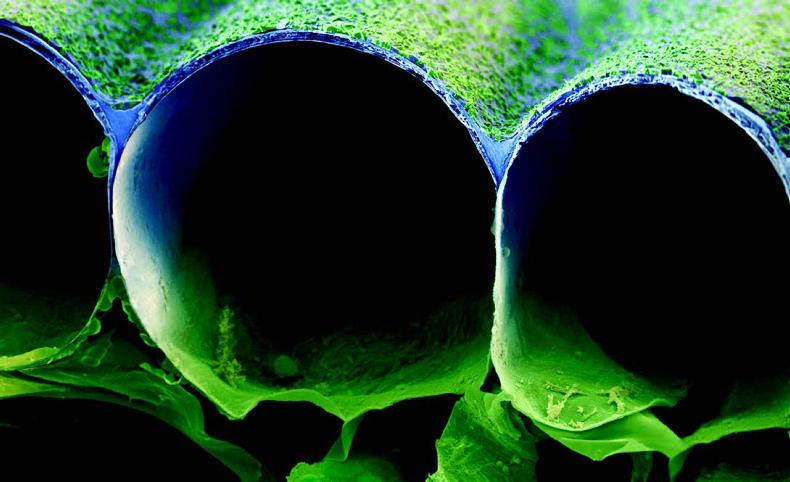

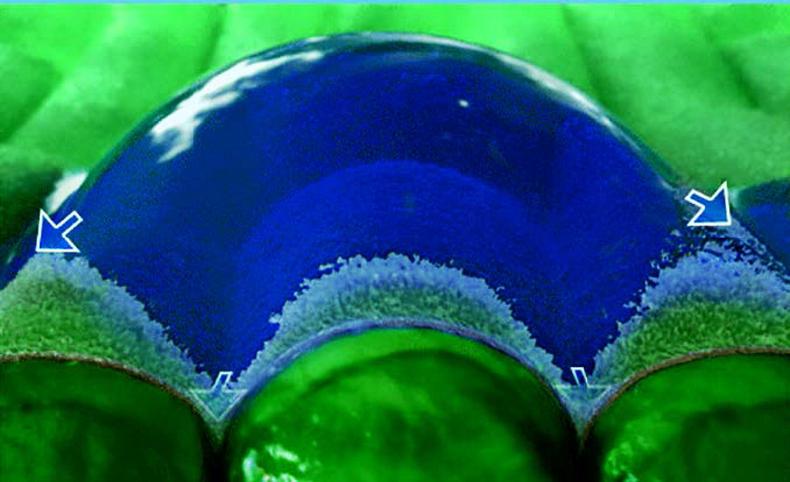

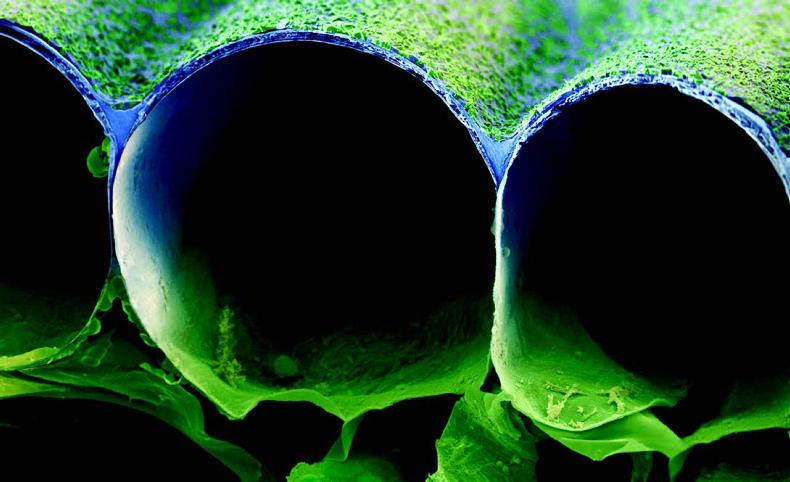

An inherently active molecule that is insoluble in water makes delivery to the site of fungus activity in a plant difficult to impossible. That was a major challenge posed following the discovery of Mefentrifluconazole, the active ingredient which will be known to us as Revysol. However, formulation chemists managed to develop a formulation that allows the active to become temporarily soluble in water; it naturally has a level of lipid solubility that enables it pass quickly through the wax layer on the leaf surface.

The company claims that Revysol gets inside the leaf surface much faster than prothioconazole; the uptake of Revysol in 1 hour is the same as prothioconazole achieves in 24 hours. This very fast uptake means two things:

It provides for strong curative activity.It is very rainfast. The rapid uptake into the leaf means that the active ingredient is protected from loss by rain and from degradation by UV light. Following application, the formulation adheres rapidly to the leaf surface and when the active moves into the leaf it assembles in a reservoir beneath the cuticle (skin) where it becomes quite insoluble again. And for this reason it is slow to move along the leaf. But it does move slowly in the transpiration system.

This provides considerable durability to the product in the leaf, thus providing long-term protection against diseases. The insolubility occurs because the adjuvants that carry the active in the spray formulation remain on the leaf surface while the active moves into the leaf.

It is unusual to get this combination of rapid uptake and slow internal movement in the same active. While very little of the product moves away from the point of application (up the leaf), the fact that the molecule is so active means that it will still provide disease control up the leaf from the point of application.

One other benefit from the formulation is its uptake in low temperatures. While this may not be needed often, it is a very useful characteristic of the active. It was also interesting to note the comment that Revysol is much less affected by UV light degradation than is prothioconazole. This is not something we have heard much about in the past but then rainfastness can rightly be seen as a more important problem for us than UV degradation. However, it was noted that prothioconazole performance is sometimes seen to be lower in high light intensity years.

Revysol appears to be hitting the ‘sweet spot’ with regard to lipid solubility, which is important to help get the active inside the leaf as quickly as possible. The formulation also appears to be really good at adhering to the leaf surface during application, thus helping to prevent run-off, and this may be particularly useful if spraying on to a damp leaf. The formulation appears to be good at spreading across the leaf surface following application and then gets through the leaf surface very rapidly.

As stated previously, once inside the leaf it becomes insoluble again and gets located just under the cuticle from where it can move. From here it provides a reservoir of active for further movement when necessary. Because it is so active, it does not require much to move to secure high activity. In general, most of the active stays close to the point of application but small amounts are consistently stripped off and these move up the leaf to protect any areas not adequately sprayed.

Disease activity

Up to now Revysol has largely been talked about in terms of its usefulness against septoria. That is partly because we badly needed new actives with good efficacy against this serious disease and partly because the product is very effective against this disease. Its efficacy is not confined to septoria. It is very good on brown rust and quite useful against yellow rust and mildew, so it has a very useful and broad spectrum of disease control in wheat.

On barley it is good so far on ramularia and offers useful mildew control relative to other triazoles. It is also quite good on brown rust in barley. However, it lags the performance of other triazoles for rhyncho control and is weaker than the other triazoles on net blotch.

Given the fact that Revysol is very active against septoria, it is hardly surprising that its use generally results in a yield benefit as well as superior septoria control. Its curative activity adds to this benefit and it can show superior benefit in delayed application situations. This is not to be recommended but it is useful to know it, when and if needed.

As well as the control of fungal diseases, BASF also emphasised the ability of the commercial products to help prevent brackling, which is now a serious problem in barley in particular.

The claims made by BASF for Revysol – superior rainfastness, rapid uptake, strong curative activity, long-lasting performance in the field, ability to work under high disease pressure, and ability to control DMI-adapted septoria strains – were tested independently by Julie Smith of ADAS in the UK. She examined the development and control of septoria in plots under natural infestation, in plots inoculated with different infection pressures and others inoculated with low-sensitivity DMI-adapted strains which are now poorly controlled by other azole fungicides.

The control treatments tested used a control or non-treated treatment, a spray with 0.72l/ha of Proline and Revysol at 1.5l/ha. These treatments were applied five days after inoculation of the specific main treatments.

The results shown in Figure 1 illustrate that Revysol had superior performance in all situations and that, where infection pressure was very high or where low-sensitivity strains were used, the septoria level in the treatments where Proline was applied was broadly similar to the untreated. Julie described the treatment using 108 (10^8) inoculation density as “a nuclear attack” but still Revysol performed very respectably under that pressure.

Another element of that work focused around the pace at which an infection could progress in the plant and the crop canopy. A snapshot in time, as shown by an individual assessment date, may not tell the full story of disease development and green leaf area destruction or retention. To this end, ADAS developed an assessment method called healthy area duration (HAD). The bigger a healthy leaf area is and the longer it persists, the greater is the yield potential of that crop.

Using HAD assessment, Julie found that treatments with Revysol produced a bigger green canopy which lasted for longer and this is a major part of higher yield delivery compared with the untreated or any other azole treatment.

Better control and for longer

Another claim made for Revysol is that it is both persistent and curative. To examine this claim, Julie applied both it and Proline 5, 10 or 15 days either side of the optimum GS39 application timing in winter wheat. Yield was barely affected with + or – five days of the optimum for Revysol and timings of 10 days early or late showed minimal effect.

While Revysol performed much better than Proline at all timings, the treatments that were applied 15 days early or late, relative to GS39, resulted in poorer yield delivery. And it was obvious from the results that it performed better when applied 15 days early rather than 15 days late when the disease would have progressed much further. Interestingly, the performance of Proline was not as much affected by timing but then it was not nearly as effective in terms of yield delivery at any timing.

Another experiment looked at the durability of the product immediately post application, specifically relating to rainfastness and infection pressure. Julie called this the Tsunami experiment. Treatment 1 in this experiment, which took place in Hereford in 2018, was covered by a polytunnel at a certain point to protect it from rainfall and septoria rain splash.

Treatment 2 was subjected to natural rainfall, ie it was open to the elements. Treatment 3 received natural rainfall plus high irrigation. Treatment 4 was like treatment 3 but it was also inoculated with septoria to increase infection pressure.

These differing pressure levels were then either untreated, sprayed with Proline at 0.72l/ha or sprayed with Revysol at 1.5l/ha on 7 June. Septoria infection was measured on the flag leaf seven, 14, 21 and 28 days later. The results showed very little septoria development in T1, with few detectable difference between the two fungicides (Figure 1). T2 showed definite differences in septoria control between the three sprays. T3 had even more septoria and, by the 28th day, the gap in favour of Revysol was substantial. T4 had huge septoria pressure and disease levels were much higher with all spray treatments. In this treatment, the untreated and Proline had 70% and 60% septoria respectively on the flag leaf while the Revysol treatment was at 35% – a lot of septoria but substantial control under severe pressure.

In other experiments on spray timing, Julie said the falling performance of azoles over the past two decades had altered the yield contribution of the different fungicide timings.

However, the sheer performance and efficacy of Revysol has taken the azole yield response curve back to where it was over two decades ago.

Julie concluded that her range of experiments had verified all the claims being made by BASF for Revysol. We must now hope that the product can continue to stand up to nature’s wrath.

The products

Two new products containing Revysol were launched earlier this year and both are mixtures of Revysol and Xemium but at different ratios.

Revystar XE is a 2:1 mix of Revysol and Xemium at 100g/l and 47.5g/l respectively. It can be used on all cereals at a maximum rate of 1.5 l/ha with up to two applications per crop.

Lentyma is a 1:1 mix at 66.7g/l of both ingredients. It is registered for use on all cereals except oats. It also has a max application rate of 1.25 l/ha with a maximum of two applications per crop.

At the launch, Steve Dennis said that there is no one single mix ratio that fits all situations. This fact gives more flexibility in having different mixes for different situations. He also said that these two mixes are better than the sum of their individual parts, which means that the products show synergy from the mix of the individual actives.

The registration of the new triazole, Revysol, late last year is a welcome introduction to the crop protection scene on these islands. This is because of the continuous weakening of the triazoles, the loss of the strobilurins, the concerns over the SDHIs and the imminent loss of chlorothalonil. Together these issues have worried grain producers for the past number of years.

The instant concern is that this is yet another triazole, and it is, but with a modified structure. This would not normally be enough in today’s climate of evolving biology, but it seems that Revysol is much more than just another triazole. Never before did we have such a handle on a new molecule at the point of its introduction.

There can be little doubt but that our background knowledge continues to increase and new molecules need to be able to tell a big story to appear impressive.

This is not just a big story. It is big in terms of a market need, as other actives are either decreasing in efficacy or being lost. But it is also big in terms of its difference as an azole and its ability to control septoria.

Chlorothalonil use is to cease on 20 May. The consequence of this is the enhanced exposure of weakening SDHI actives to continuously weakening triazoles. So what will yet another azole do?

Fungicide/fungus relationship

One of the major differences that Revysol brings is the ability of the molecule to flex and assume different physical shapes. This is because one component of the molecule, called the isopropanol linker, enables its shape to flex to fit variable shapes.

The new azole, Revysol, carries a novel formulation which enables it dissolve in water for application.

Let’s backtrack a little. A fungicide/fungus interaction is often described as a lock and key. When they are an exact fit the fungicide can act to kill the fungus. But if there is a slight alteration in the lock (fungus), the key (fungicide) will no longer work. An equivalent description of the process is a hand and glove comparison – when they fit comfortably together, the fungus can be killed.

Once inside the leaf, Revysol sits just beneath the leaf cuticle and from there it moves very slowly to provide both curative and protectant disease control.

Staying with the glove simile (the fungus), in shape terms it is the ‘thumb’ that is the important bit because that is where the azole component of the molecule fits into the enzyme to prevent it from working and so stop fungus growth. According to BASF, the main reason for decreased triazole sensitivity is an alteration to the positioning of the ‘thumb’ in the target enzyme in the fungus.

If we assume that the original triazoles worked well in the ‘thumbs up’ position, fungicide efficacy would be poor when most of the enzymes had a ‘thumbs out’ or ‘thumbs back’ position. While this simile is solely for description purposes, BASF people say that known mutations which limit azole activity fit this description.

The company says the uniqueness of the isopropanol linker component of the molecule enables it to fit comfortably into known mutation positions and so provide excellent control of all septoria, the mutations and the wild types.

The challenge of keeping wheat crops free of septoria seems feasible again following the introduction of Revysol.

The inevitable follow-on question here is, will the active be able to kill mutations that we are not yet even aware of? According to Steve Dennis of BASF, it seems possible that this unique flexibility, which is referred to as Revysol Flexi-Power, will cope with future enzyme shape-related mutations at this point. Steve said that scientists generally believe that there is a limit to the structural change that can occur in this enzyme and that this molecule can cope with these. It is thought that change in the enzyme beyond which the molecule can achieve is likely to naturally limit the fungus itself.

So the principle here is that the molecule can adapt to the shape of the binding pocket in the enzyme in the fungus. But that is not its only strength.

Binding power

Another stated element of the exceptional performance of Revysol is its binding power once it comes in contact with the enzyme in the fungus. Even where the key fits the lock or the hand fits the glove perfectly, it was suggested that these couplings are actually less permanent than we might have been led to believe in the past. Steve suggests that it was not uncommon for the key or the hand to come out again, possibly because there is a small element of movement in all molecules which may cause them to be displaced.

Whether that be perfectly true or not, BASF claims that Revysol binds to the enzyme on average over 100 times more powerfully than conventional azoles. In saying that, some are better than others, but the benefit seems tangible. This is given as the reason for the very strong fungicidal efficacy exhibited by the compound. It also helps to explain its efficacy despite slow mobility in the plant.

The azole challenge

We in Ireland are very aware of the failing efficacy of azoles against septoria and ramularia in particular. But this is not the only problem that azoles have, as the group has largely become subject to the endocrine disruptor element of the Sustainable Use Directive legislation. This has been a subject of some debate for many years now and so it is a real concern for all azoles and especially for new azoles.

It appears that most azoles are now likely to be revoked due to this inherent characteristic, so endocrine disruption has become a significant obstacle for any new active. To put this in perspective, our fungicides target what is known as the CYP 51 enzyme, which is involved in cell wall formation in the fungus and if there is no cell wall, there is no fungus. This is an ‘on-target’ effect.

While this new active appears quite active and robust, we must still aim to have it applied at the correct timings and be sensible about application rate and how we protect it.

The problem is that the same active can also target the CYP 19 enzyme in the mammalian endocrine system, which is an ‘off-target’ effect. An active with this characteristic can have a potentially hazardous impact on mammalian reproductive systems. So, the challenge for any new azole is to have a big impact on CYP 51 and little or no impact on CYP 19.

This ‘off-target’ effect seems to be mainly related to the structure of that part of the molecule which is not the azole element. BASF says that Revysol manages to optimise its relative impact on these two targets.

Formulation characteristics

An inherently active molecule that is insoluble in water makes delivery to the site of fungus activity in a plant difficult to impossible. That was a major challenge posed following the discovery of Mefentrifluconazole, the active ingredient which will be known to us as Revysol. However, formulation chemists managed to develop a formulation that allows the active to become temporarily soluble in water; it naturally has a level of lipid solubility that enables it pass quickly through the wax layer on the leaf surface.

The company claims that Revysol gets inside the leaf surface much faster than prothioconazole; the uptake of Revysol in 1 hour is the same as prothioconazole achieves in 24 hours. This very fast uptake means two things:

It provides for strong curative activity.It is very rainfast. The rapid uptake into the leaf means that the active ingredient is protected from loss by rain and from degradation by UV light. Following application, the formulation adheres rapidly to the leaf surface and when the active moves into the leaf it assembles in a reservoir beneath the cuticle (skin) where it becomes quite insoluble again. And for this reason it is slow to move along the leaf. But it does move slowly in the transpiration system.

This provides considerable durability to the product in the leaf, thus providing long-term protection against diseases. The insolubility occurs because the adjuvants that carry the active in the spray formulation remain on the leaf surface while the active moves into the leaf.

It is unusual to get this combination of rapid uptake and slow internal movement in the same active. While very little of the product moves away from the point of application (up the leaf), the fact that the molecule is so active means that it will still provide disease control up the leaf from the point of application.

One other benefit from the formulation is its uptake in low temperatures. While this may not be needed often, it is a very useful characteristic of the active. It was also interesting to note the comment that Revysol is much less affected by UV light degradation than is prothioconazole. This is not something we have heard much about in the past but then rainfastness can rightly be seen as a more important problem for us than UV degradation. However, it was noted that prothioconazole performance is sometimes seen to be lower in high light intensity years.

Revysol appears to be hitting the ‘sweet spot’ with regard to lipid solubility, which is important to help get the active inside the leaf as quickly as possible. The formulation also appears to be really good at adhering to the leaf surface during application, thus helping to prevent run-off, and this may be particularly useful if spraying on to a damp leaf. The formulation appears to be good at spreading across the leaf surface following application and then gets through the leaf surface very rapidly.

As stated previously, once inside the leaf it becomes insoluble again and gets located just under the cuticle from where it can move. From here it provides a reservoir of active for further movement when necessary. Because it is so active, it does not require much to move to secure high activity. In general, most of the active stays close to the point of application but small amounts are consistently stripped off and these move up the leaf to protect any areas not adequately sprayed.

Disease activity

Up to now Revysol has largely been talked about in terms of its usefulness against septoria. That is partly because we badly needed new actives with good efficacy against this serious disease and partly because the product is very effective against this disease. Its efficacy is not confined to septoria. It is very good on brown rust and quite useful against yellow rust and mildew, so it has a very useful and broad spectrum of disease control in wheat.

On barley it is good so far on ramularia and offers useful mildew control relative to other triazoles. It is also quite good on brown rust in barley. However, it lags the performance of other triazoles for rhyncho control and is weaker than the other triazoles on net blotch.

Given the fact that Revysol is very active against septoria, it is hardly surprising that its use generally results in a yield benefit as well as superior septoria control. Its curative activity adds to this benefit and it can show superior benefit in delayed application situations. This is not to be recommended but it is useful to know it, when and if needed.

As well as the control of fungal diseases, BASF also emphasised the ability of the commercial products to help prevent brackling, which is now a serious problem in barley in particular.

The claims made by BASF for Revysol – superior rainfastness, rapid uptake, strong curative activity, long-lasting performance in the field, ability to work under high disease pressure, and ability to control DMI-adapted septoria strains – were tested independently by Julie Smith of ADAS in the UK. She examined the development and control of septoria in plots under natural infestation, in plots inoculated with different infection pressures and others inoculated with low-sensitivity DMI-adapted strains which are now poorly controlled by other azole fungicides.

The control treatments tested used a control or non-treated treatment, a spray with 0.72l/ha of Proline and Revysol at 1.5l/ha. These treatments were applied five days after inoculation of the specific main treatments.

The results shown in Figure 1 illustrate that Revysol had superior performance in all situations and that, where infection pressure was very high or where low-sensitivity strains were used, the septoria level in the treatments where Proline was applied was broadly similar to the untreated. Julie described the treatment using 108 (10^8) inoculation density as “a nuclear attack” but still Revysol performed very respectably under that pressure.

Another element of that work focused around the pace at which an infection could progress in the plant and the crop canopy. A snapshot in time, as shown by an individual assessment date, may not tell the full story of disease development and green leaf area destruction or retention. To this end, ADAS developed an assessment method called healthy area duration (HAD). The bigger a healthy leaf area is and the longer it persists, the greater is the yield potential of that crop.

Using HAD assessment, Julie found that treatments with Revysol produced a bigger green canopy which lasted for longer and this is a major part of higher yield delivery compared with the untreated or any other azole treatment.

Better control and for longer

Another claim made for Revysol is that it is both persistent and curative. To examine this claim, Julie applied both it and Proline 5, 10 or 15 days either side of the optimum GS39 application timing in winter wheat. Yield was barely affected with + or – five days of the optimum for Revysol and timings of 10 days early or late showed minimal effect.

While Revysol performed much better than Proline at all timings, the treatments that were applied 15 days early or late, relative to GS39, resulted in poorer yield delivery. And it was obvious from the results that it performed better when applied 15 days early rather than 15 days late when the disease would have progressed much further. Interestingly, the performance of Proline was not as much affected by timing but then it was not nearly as effective in terms of yield delivery at any timing.

Another experiment looked at the durability of the product immediately post application, specifically relating to rainfastness and infection pressure. Julie called this the Tsunami experiment. Treatment 1 in this experiment, which took place in Hereford in 2018, was covered by a polytunnel at a certain point to protect it from rainfall and septoria rain splash.

Treatment 2 was subjected to natural rainfall, ie it was open to the elements. Treatment 3 received natural rainfall plus high irrigation. Treatment 4 was like treatment 3 but it was also inoculated with septoria to increase infection pressure.

These differing pressure levels were then either untreated, sprayed with Proline at 0.72l/ha or sprayed with Revysol at 1.5l/ha on 7 June. Septoria infection was measured on the flag leaf seven, 14, 21 and 28 days later. The results showed very little septoria development in T1, with few detectable difference between the two fungicides (Figure 1). T2 showed definite differences in septoria control between the three sprays. T3 had even more septoria and, by the 28th day, the gap in favour of Revysol was substantial. T4 had huge septoria pressure and disease levels were much higher with all spray treatments. In this treatment, the untreated and Proline had 70% and 60% septoria respectively on the flag leaf while the Revysol treatment was at 35% – a lot of septoria but substantial control under severe pressure.

In other experiments on spray timing, Julie said the falling performance of azoles over the past two decades had altered the yield contribution of the different fungicide timings.

However, the sheer performance and efficacy of Revysol has taken the azole yield response curve back to where it was over two decades ago.

Julie concluded that her range of experiments had verified all the claims being made by BASF for Revysol. We must now hope that the product can continue to stand up to nature’s wrath.

The products

Two new products containing Revysol were launched earlier this year and both are mixtures of Revysol and Xemium but at different ratios.

Revystar XE is a 2:1 mix of Revysol and Xemium at 100g/l and 47.5g/l respectively. It can be used on all cereals at a maximum rate of 1.5 l/ha with up to two applications per crop.

Lentyma is a 1:1 mix at 66.7g/l of both ingredients. It is registered for use on all cereals except oats. It also has a max application rate of 1.25 l/ha with a maximum of two applications per crop.

At the launch, Steve Dennis said that there is no one single mix ratio that fits all situations. This fact gives more flexibility in having different mixes for different situations. He also said that these two mixes are better than the sum of their individual parts, which means that the products show synergy from the mix of the individual actives.

SHARING OPTIONS