DeLaval is one of the bigger players internationally when it comes to milking machinery and dairy farm technology. The organisation has 18 factories dotted across the world and is home to over 4,500 employees.

The Irish Farmers Journal recently had the exciting opportunity to travel to Sweden, the home of DeLaval. The visit was to mark the official opening of the development works that took place at Hamra farm, DeLaval’s commercial farm for research and development (R&D).

Hamra is located in the Tumba region, approximately 30km south of the Swedish capital, Stockholm.

Factory

While the purpose of the visit was to mark the developments at the impressive farm facility, the Irish Farmers Journal also gained access to the DeLaval factory on the day.

The factory in Tumba is one of 18 worldwide and is the site where the majority of DeLaval’s robot milking machines are finished from.

The process is highly automated but the assembly of the machines and the logic behind the technology is still very much done by humans.

There is just one shift in the factory, with all staff abiding by a lean operational practice.

The factory floor is broken up into smaller sections where four to five employees work on manufacturing particular parts of the machine.

There is a team lead at each station, with line managers overseeing the entire process. Through the middle of the factory runs an assembly carousel, akin to something you would see in a Formula 1 team shop.

The robot machines start at the first section of the carousel as a bare looking frame.

Every 15 minutes the carousel moves, with the small team at each section expected to have their portion of the assembly completed by the time the clock hits zero. This process keeps everyone very much on their toes with no time for hanging around.

As the milking robot moves around the carousel from stop to stop, it begins to look more and more like the robots one sees in a milking shed. By the final stop, the product is ready to be boxed up and delivered to the customers. The country of destination is listed on each robot with the nations flag attached.

The ones we saw on the day were destined for places like Hungary, Germany, Poland and the Netherlands.

The whole process was highly digitised with each station on the assembly line requesting the part they need via a tablet.

Once the message was relayed from the tablet at the carousel to the relevant manufacturing station, a small robot on wheels came whizzing by to act as the delivery driver.

DeLaval is quite rightly proud of the level of efficiency that is in place across its factories.

The site is also a major employer in the area with close to 200 local people employed at the facility.

DeLaval Optimat feed system.

Hamra Farm

While the factory proved an impressive site, the primary reason for the open day was to explore the new developments that have occurred on the Hamra farm.

The farm, located across the road from the main headquarters, is there to support R&D, trials and learning. It allows DeLaval to provide a better product that’s tried and tested in a real farm environment before selling to the customer.

The new development was the largest in the farm’s history, spanning 12,000m2 and including three new barns: a maternity and calf barn, a heifer barn and a milking cow barn that doubles up as a state-of-the-art visitor centre.

All in, the development has increased the capacity of the farm from 260 cows up to 550 cows, with room for a further 500 youngstock.

At the time of the visit the farm had 170 cows in milk, with plans to expand the herd to 350 cows in the next year. There are five DeLaval robots in the shed, capable of milking 75 cows each.

The cows are a 50:50 split of Holstein’s and Swedish Red’s with an average annual production of 12,600l/year. The cows are fed between 40kg to 44kg each of dry-matter per day, with the standard diet consisting of grass and maize silage, barley and high levels of meal.

The main milking shed is equipped with all of DeLaval’s latest technology including the Optimat feed system and the DeLaval’s robot scraper.

The Optimat technology is targeted for indoor systems, as it mixes the different feeds together into a TMR and distributes it to the cows at regular intervals throughout the day, ensuring there is fresh feed always available.

Once the farmer loads the mixer, the rest of the work is done automatically. A conveyor belt moves the feed from the mixing point into the waiting feed trailers. The feed trailers then move around the shed according to a programmed route allocating fresh feed to the cows around five times per day.

The DeLaval robot scraper RS450S works to scrape all manure from central passages to a slurry storage tank several times throughout the day. The newer models are updated with silent motors and lower speeds to prevent disturbances to cows.

On top of all of this, the sheds are automatically bedded with sawdust via an automated overhead cubicle bedder.

The staff scrape off the cubicles several times throughout the day and fresh sawdust is released from an overhead machine onto the empty cubicle below.

If a cow is lying down, the bedder will move onto the next empty cubicle before dropping the sawdust ensuring no waste. This particular product is not fully developed for sale yet.

DeLaval robot scraper working to clean behind the cows.

DeLaval VMS V300

The real star of the show in the new Hamra development was the latest edition of the DeLaval milking robots. The newest model is called the DeLaval VMS V300 2025 version, and offers some advanced features on previous VMS models.

According to DeLaval, the 2025 edition of the V300 is a faster, more efficient and more comfortable model for the cow.

Flow-responsive milking is the main reason for the enhanced cow experience.

The machine maintains constant teat-end vacuum regardless of milk volume and flow meaning a more comfortable and faster milking time, according to DeLaval.

On the day of the visit a DeLaval employee explained that research from the University of Wisconsin had shown that the newer models could shorten the milking time by 27 seconds on average with up to 50% less kick-offs.

Saving

This saving could mean an extra three to five cows milked per robot per day. The newest model is also slightly bigger with more room for larger high-yielding cows and incorporates milk-cell analysis technology.

Milk-cell analysis is a real-time cell count detector and can help identify cows with high cell counts and cases of subclinical mastitis after each milking to allow for faster intervention.

Automated milking systems and milking robots are rapidly increasing in popularity across Europe and the wider world according to Jonas Hallman, executive vice president at DeLaval for Europe, Middle East and Africa.

Over 40% of DeLaval’s revenue is now coming from investments in robots, or voluntary milking systems (VMS) as it calls them.

The increasing difficulty in securing labour, coupled with the consolidation that’s taking place on farms across Europe, has seen robotic milking go from strength to strength.

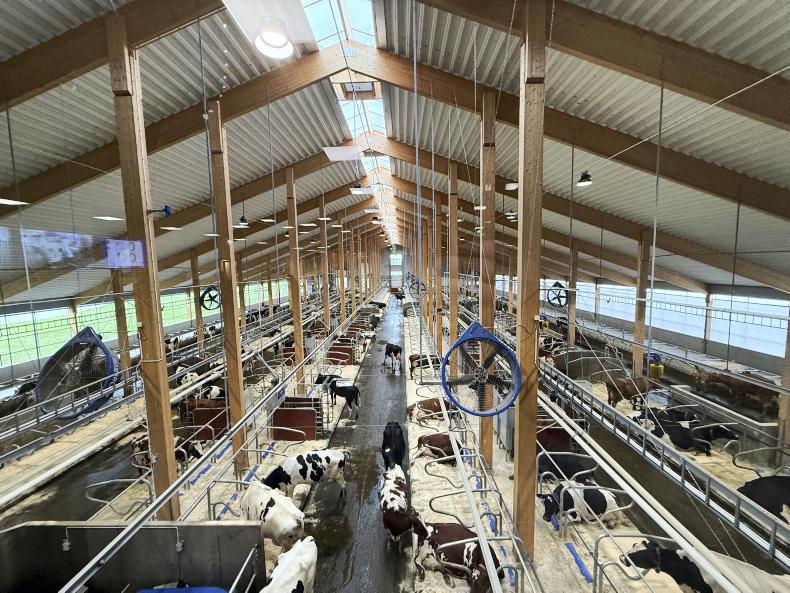

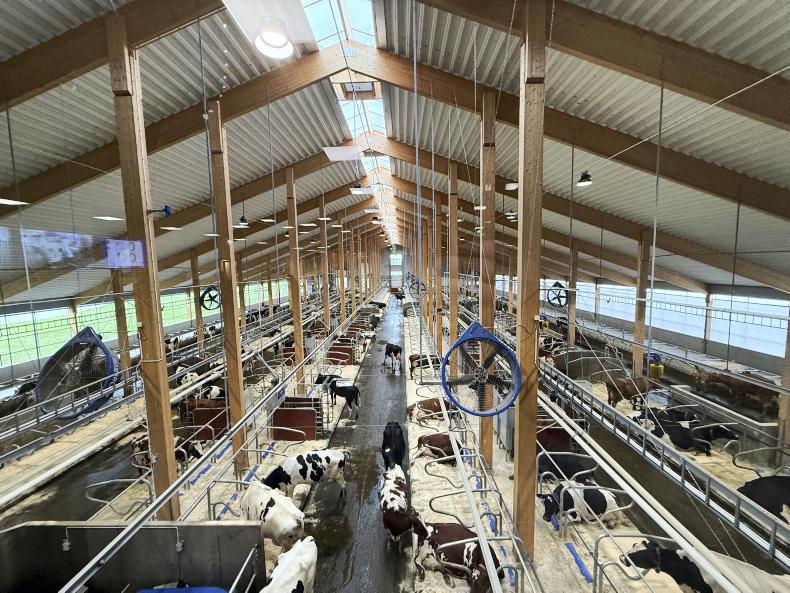

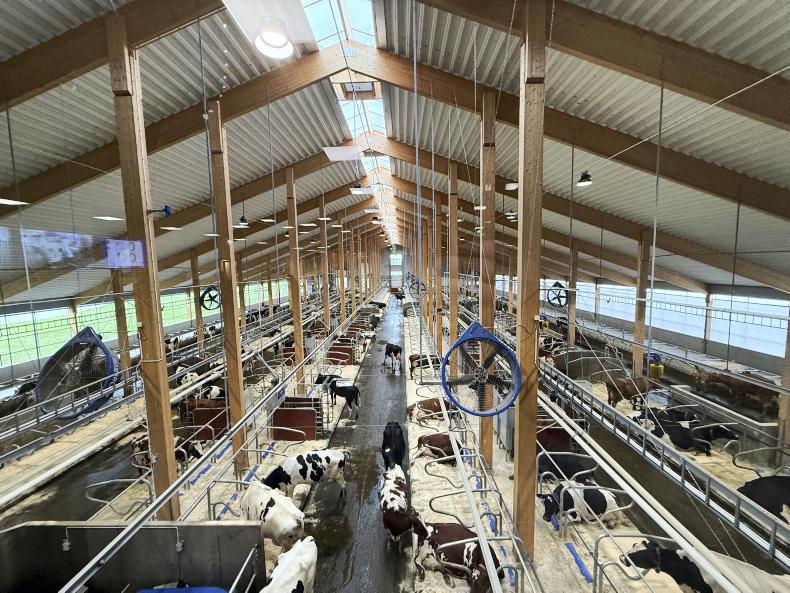

The new state-of-the-art milking cow barn.

Batch milking

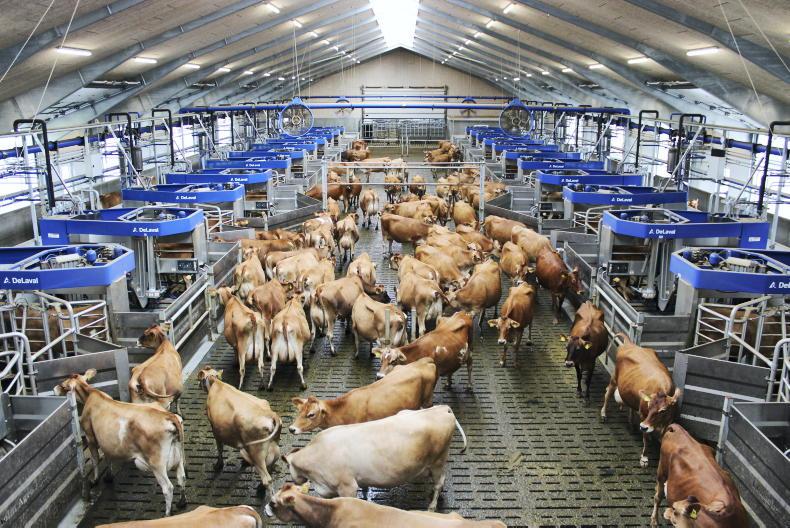

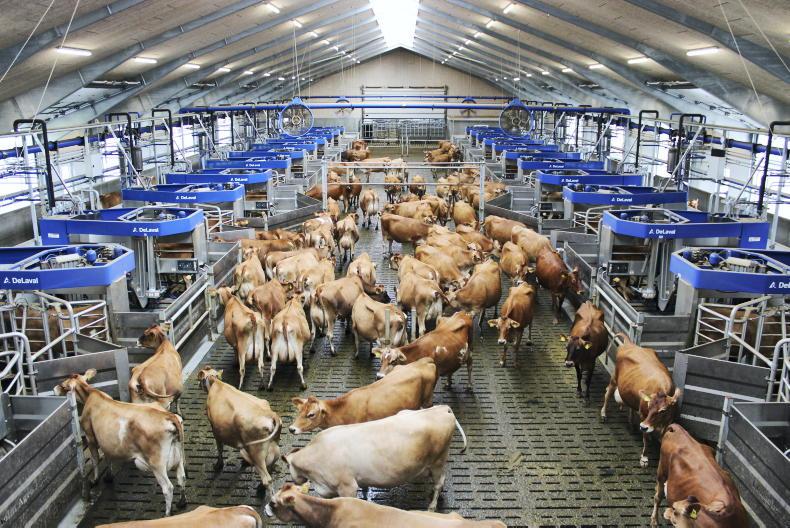

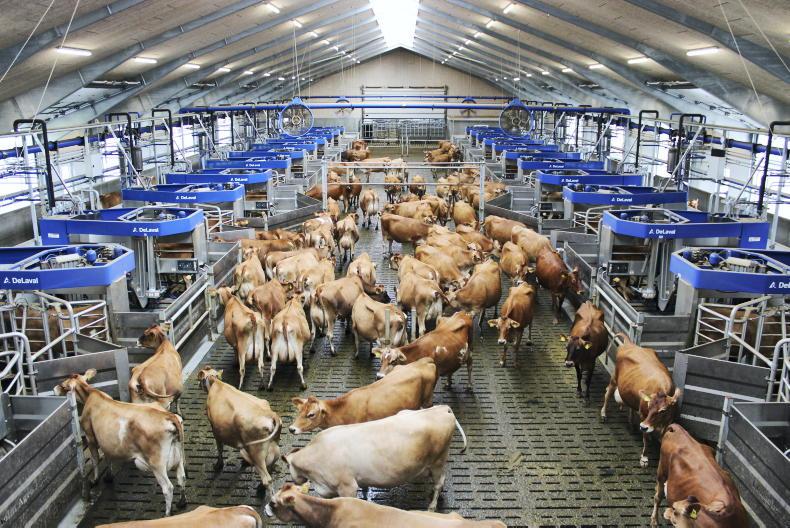

Batch milking systems are something DeLaval has been seeing more interest in, particularly from farmers in grass-based systems and at larger scale.

A batch milking system is one with several robots located under one roof.

The robots are located around a collecting yard.

The cows are then brought from the paddock or cubicles to the collecting yard in big groups.

Like a normal milking system, the cows wait in the collecting yard until a robot becomes free.

Return

As cows are milked, they return to the paddock or shed like they would from a herringbone parlour or a rotary.

The advantage of this system is just one person is required to milk a large number of cows and the ABC setup for grazing that’s normally associated with robots is not required. The single operator is just bringing cows from the field or the shed twice a day to the collecting yard before going about their other daily tasks.

Scale is needed for such a system though as it requires a big investment in a larger number of robots in the first place.

De Laval VMS V300 model.

In short

DeLaval is operating in 100 countries worldwide, with 18 factories and over 4,500 employees.The DeLaval headquarters is located in Tumba, approximately 30km south of Sweden’s capital Stockholm.It held an open day recently to mark the expansion of its research and development farm in Tumba. The investment has seen the capacity of the farm rise to 550 cows and over 1,000 animals in total.The new development includes some of DeLaval’s latest technology like the impressive Optimat feeding system and the latest edition of the VMS V300 robot.

The view of a batch milking system.

DeLaval is one of the bigger players internationally when it comes to milking machinery and dairy farm technology. The organisation has 18 factories dotted across the world and is home to over 4,500 employees.

The Irish Farmers Journal recently had the exciting opportunity to travel to Sweden, the home of DeLaval. The visit was to mark the official opening of the development works that took place at Hamra farm, DeLaval’s commercial farm for research and development (R&D).

Hamra is located in the Tumba region, approximately 30km south of the Swedish capital, Stockholm.

Factory

While the purpose of the visit was to mark the developments at the impressive farm facility, the Irish Farmers Journal also gained access to the DeLaval factory on the day.

The factory in Tumba is one of 18 worldwide and is the site where the majority of DeLaval’s robot milking machines are finished from.

The process is highly automated but the assembly of the machines and the logic behind the technology is still very much done by humans.

There is just one shift in the factory, with all staff abiding by a lean operational practice.

The factory floor is broken up into smaller sections where four to five employees work on manufacturing particular parts of the machine.

There is a team lead at each station, with line managers overseeing the entire process. Through the middle of the factory runs an assembly carousel, akin to something you would see in a Formula 1 team shop.

The robot machines start at the first section of the carousel as a bare looking frame.

Every 15 minutes the carousel moves, with the small team at each section expected to have their portion of the assembly completed by the time the clock hits zero. This process keeps everyone very much on their toes with no time for hanging around.

As the milking robot moves around the carousel from stop to stop, it begins to look more and more like the robots one sees in a milking shed. By the final stop, the product is ready to be boxed up and delivered to the customers. The country of destination is listed on each robot with the nations flag attached.

The ones we saw on the day were destined for places like Hungary, Germany, Poland and the Netherlands.

The whole process was highly digitised with each station on the assembly line requesting the part they need via a tablet.

Once the message was relayed from the tablet at the carousel to the relevant manufacturing station, a small robot on wheels came whizzing by to act as the delivery driver.

DeLaval is quite rightly proud of the level of efficiency that is in place across its factories.

The site is also a major employer in the area with close to 200 local people employed at the facility.

DeLaval Optimat feed system.

Hamra Farm

While the factory proved an impressive site, the primary reason for the open day was to explore the new developments that have occurred on the Hamra farm.

The farm, located across the road from the main headquarters, is there to support R&D, trials and learning. It allows DeLaval to provide a better product that’s tried and tested in a real farm environment before selling to the customer.

The new development was the largest in the farm’s history, spanning 12,000m2 and including three new barns: a maternity and calf barn, a heifer barn and a milking cow barn that doubles up as a state-of-the-art visitor centre.

All in, the development has increased the capacity of the farm from 260 cows up to 550 cows, with room for a further 500 youngstock.

At the time of the visit the farm had 170 cows in milk, with plans to expand the herd to 350 cows in the next year. There are five DeLaval robots in the shed, capable of milking 75 cows each.

The cows are a 50:50 split of Holstein’s and Swedish Red’s with an average annual production of 12,600l/year. The cows are fed between 40kg to 44kg each of dry-matter per day, with the standard diet consisting of grass and maize silage, barley and high levels of meal.

The main milking shed is equipped with all of DeLaval’s latest technology including the Optimat feed system and the DeLaval’s robot scraper.

The Optimat technology is targeted for indoor systems, as it mixes the different feeds together into a TMR and distributes it to the cows at regular intervals throughout the day, ensuring there is fresh feed always available.

Once the farmer loads the mixer, the rest of the work is done automatically. A conveyor belt moves the feed from the mixing point into the waiting feed trailers. The feed trailers then move around the shed according to a programmed route allocating fresh feed to the cows around five times per day.

The DeLaval robot scraper RS450S works to scrape all manure from central passages to a slurry storage tank several times throughout the day. The newer models are updated with silent motors and lower speeds to prevent disturbances to cows.

On top of all of this, the sheds are automatically bedded with sawdust via an automated overhead cubicle bedder.

The staff scrape off the cubicles several times throughout the day and fresh sawdust is released from an overhead machine onto the empty cubicle below.

If a cow is lying down, the bedder will move onto the next empty cubicle before dropping the sawdust ensuring no waste. This particular product is not fully developed for sale yet.

DeLaval robot scraper working to clean behind the cows.

DeLaval VMS V300

The real star of the show in the new Hamra development was the latest edition of the DeLaval milking robots. The newest model is called the DeLaval VMS V300 2025 version, and offers some advanced features on previous VMS models.

According to DeLaval, the 2025 edition of the V300 is a faster, more efficient and more comfortable model for the cow.

Flow-responsive milking is the main reason for the enhanced cow experience.

The machine maintains constant teat-end vacuum regardless of milk volume and flow meaning a more comfortable and faster milking time, according to DeLaval.

On the day of the visit a DeLaval employee explained that research from the University of Wisconsin had shown that the newer models could shorten the milking time by 27 seconds on average with up to 50% less kick-offs.

Saving

This saving could mean an extra three to five cows milked per robot per day. The newest model is also slightly bigger with more room for larger high-yielding cows and incorporates milk-cell analysis technology.

Milk-cell analysis is a real-time cell count detector and can help identify cows with high cell counts and cases of subclinical mastitis after each milking to allow for faster intervention.

Automated milking systems and milking robots are rapidly increasing in popularity across Europe and the wider world according to Jonas Hallman, executive vice president at DeLaval for Europe, Middle East and Africa.

Over 40% of DeLaval’s revenue is now coming from investments in robots, or voluntary milking systems (VMS) as it calls them.

The increasing difficulty in securing labour, coupled with the consolidation that’s taking place on farms across Europe, has seen robotic milking go from strength to strength.

The new state-of-the-art milking cow barn.

Batch milking

Batch milking systems are something DeLaval has been seeing more interest in, particularly from farmers in grass-based systems and at larger scale.

A batch milking system is one with several robots located under one roof.

The robots are located around a collecting yard.

The cows are then brought from the paddock or cubicles to the collecting yard in big groups.

Like a normal milking system, the cows wait in the collecting yard until a robot becomes free.

Return

As cows are milked, they return to the paddock or shed like they would from a herringbone parlour or a rotary.

The advantage of this system is just one person is required to milk a large number of cows and the ABC setup for grazing that’s normally associated with robots is not required. The single operator is just bringing cows from the field or the shed twice a day to the collecting yard before going about their other daily tasks.

Scale is needed for such a system though as it requires a big investment in a larger number of robots in the first place.

De Laval VMS V300 model.

In short

DeLaval is operating in 100 countries worldwide, with 18 factories and over 4,500 employees.The DeLaval headquarters is located in Tumba, approximately 30km south of Sweden’s capital Stockholm.It held an open day recently to mark the expansion of its research and development farm in Tumba. The investment has seen the capacity of the farm rise to 550 cows and over 1,000 animals in total.The new development includes some of DeLaval’s latest technology like the impressive Optimat feeding system and the latest edition of the VMS V300 robot.

The view of a batch milking system.

SHARING OPTIONS