Situated in the farming stronghold of Markethill, Co Armagh, Stephen Downard runs a dairy calf-to-beef enterprise with his brother Paul and father Alex, alongside working off-farm full-time. In 2012, Stephen and his wife, Carol ventured into the broiler poultry sector, which has expanded to six units containing up to 172,000 birds.

In search of a slightly more capable machine to replace his KT276, Stephen took delivery of the country’s first Kramer KT316 telehandler model earlier in the summer, following its debut at Balmoral Show in May. The machine in question sports all the optional bells and whistles, including Kramer’s Smart Attach, a hands-free, hydraulic, third service coupling system.

Background

Prior to the poultry, a tractor and front loader took care of all feeding and loader tasks on the farm. With a height restriction of 2.3m inside the poultry sheds, a more compact alternative to the tractor and front loader was needed. Aside from general farm work, a telehandler is used to clear litter out of the poultry sheds and load trucks.

In 2012, a used Manitou MLT 634 was bought an ran for six years, before switching to a Kramer KT276 in 2018.

Having felt that the Manitou was a little on the large side and getting on in age, Stephen decided to look at a replacement.

Local John Deere dealers, Johnston Gilpin were selling Kramer which he decided to enquire about. The most suitable model was the compact KT276, offering slightly less lift capacity at 2,7t and a 6m reach.

Manitou did offer an MLT 625 model but he felt the KT276 had the edge in terms of capacity, and so it was later purchased. It worked away trouble free until traded for the new model KT316 this summer.

With a better selection of 3,000kg/6m models on the market this time around, Stephen did enquire about Manitou’s MLT 630-115 V CP model. In the end, he stuck with Kramer based on a number of factors, including value for money and the reliability of his previous machine.

Steven feels the storage compartment under the steps should be hinged from either the left or right side to avoid damage in the event that it is not closed.

KT316

The KT316 is a brand-new compact model platform from Kramer to broaden its range. The newcomer slots between the smaller KT276 and KT356 models, suiting medium-sized livestock farms and situations where space is restricted like inside poultry sheds.

The KT316 is slightly larger than the KT276, measuring 2.15m high, 2.09m wide and 4.5m long in comparison to the KT276 with respective dimensions of 2.1m, 1.96m and 4.4m in the high cab version. This marginal increase made the KT316 an ideal fit for the Downards’ farm.

“Having come form a slightly larger machine originally, we missed the extra capacity when handling the shear grab and bales, etc. The guys at Kramer knew I was always after something a little bigger, and so they contacted me about the KT316. We were due to change our machine, at the time anyway,” Stephen outlined.

Engine and transmission

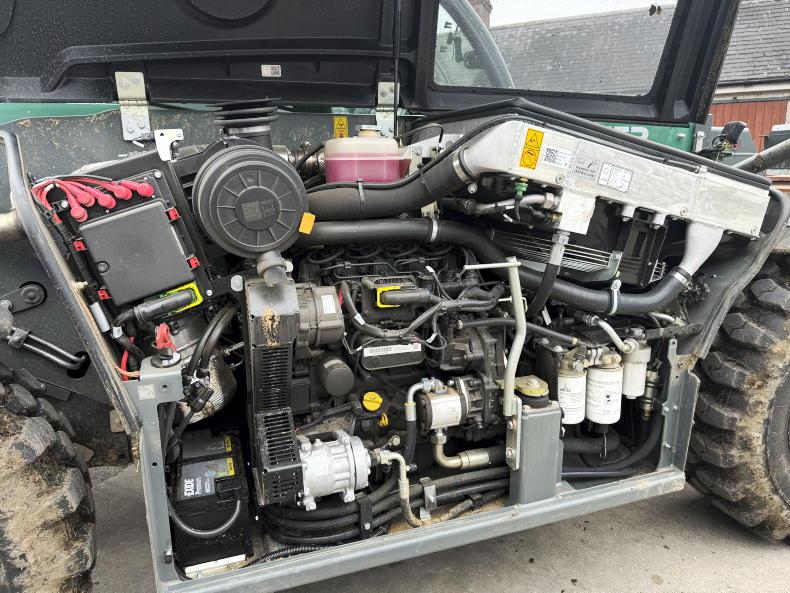

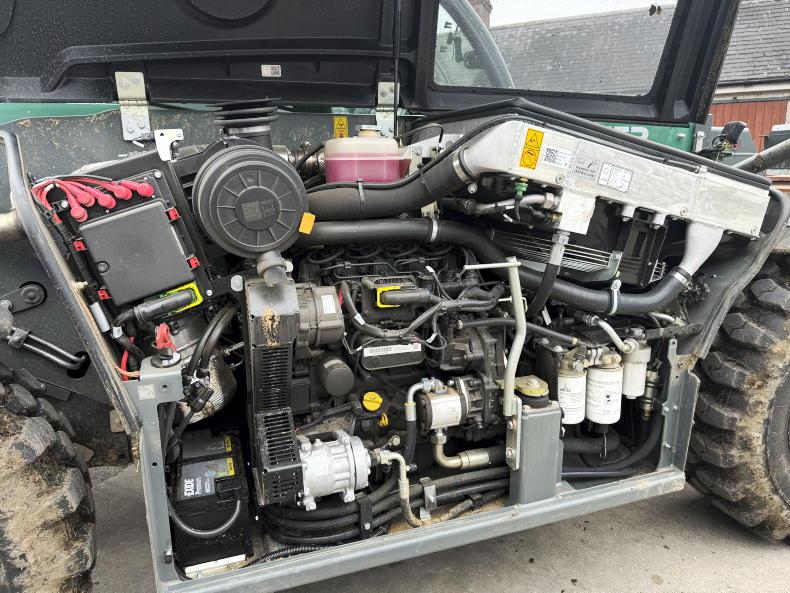

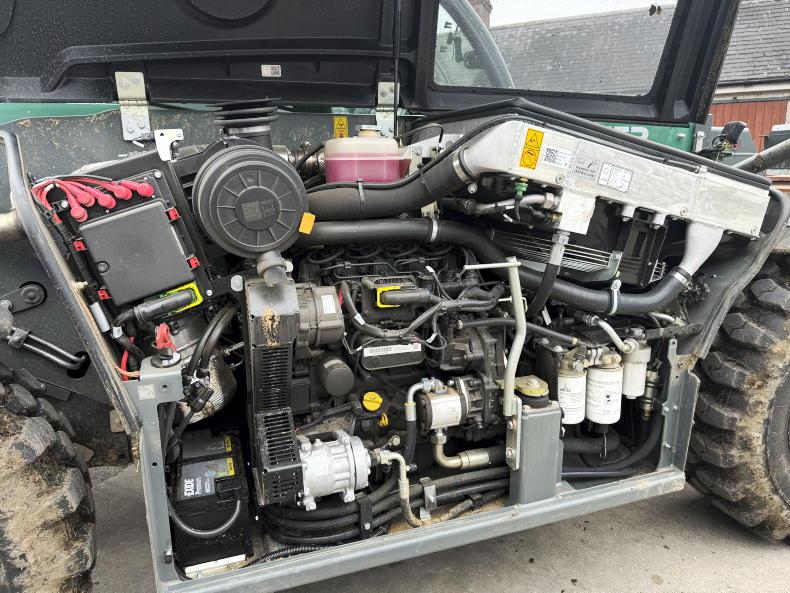

Underneath the bonnet, the KT316 offers more grunt. It is fitted with a 112hp, 2.9l Deutz engine, 109l/min hydraulic pump and a 40km/h transmission as standard.

In comparison, the KT276 was equipped with a 72hp Kohler engine, 103l/min hydraulics and a 20km/h transmission, as standard (40km/h option).

Stephen’s machine was fitted with the standard unit. The faster, 40km/h transmission in the KT316 is a huge benefit when travelling to different blocks of land, he said. To lower his machine a further 50-60mm, Stephen opted for 20in rims instead of the larger 24in.

With no shortage of dips and hollows around Markethill, Stephen said that the KT316, given its extra horsepower, is much more capable on hills and doesn’t die back as much on approach. As standard, there are three preset driving modes: power, eco and constant speed drive (CSD). It is also fitted with the reversible fan option, which Stephen noted is good, especially when working in the poultry sheds where a lot of dust tends to get pulled in. By opening the bonnet and removing the lower side panel, full access can be gained to the entire engine bay, a feature Stephen likes.

Access to the engine bay is super.

The Smart Attach headstock eliminates the need to exit the cab and manually connect third service hydraulic couplings.

Capacities

The KT316 has a maximum lift capacity of 3,100kg and a maximum reach of 5.83m. The main attachments used on the Downards’ farm include a 6ft shear grab, a 7ft bucket, pallet forks, a bale squeeze and a brush. The KT316 is equipped with a smart hydraulic system with pressure compensation, leaving it better suited for multitasking and making full use of the 109l/min flow. The Smart Attach third service quick-coupling system, removes the need to get in and out of the cab when connecting/disconnecting the shear grab.

Cab

Although cab dimensions are identical to the KT276, control layout and fit and finish has improved, Stephen feels. One new feature making entry and exit from the cab easier is the notched floor which allows better access to the step. The notch disappears once the door is closed.

Also fitted to the machine is the optional 7in display terminal. All relevant machine data is summarised on the home screen, while adjustments to machine parameters can be made on the dedicated screens and via the rotary dial.

From here, hydraulic flow can be finely tuned to the individual boom and headstock rams. Downards’ machine is equipped with a long list of other options, such as automatic bucket return, lifting and lowering height limiter functions, rear pickup hitch with dual-line hydraulic brakes and a rear-view camera system.

In terms of visibility from the cab, Stephen feels that is ahead of anything else he has sat in to date, particularly out across the bonnet. The machine is also kitted out with the full LED work light package, which the family rate highly.

The only minor critiques Stephen has regarding the cab was the storage box alongside the step. He feels that if it was hinged on the left or right then it would be better protected in the event it was accidentally left open. Another tweak, but also not a deal breaker, would be an electric handbrake over a manual handbrake.

Downards machine is equipped with a pickup hitch with rear spools and dual-line brakes.

The notch in the cab floor greatly improves access in and out of the cab.

The optional 7in terminal displays all machine information and parameter settings.

Verdict

With seven years’ experience running Kramer, Stephen is more than happy with the product and the backup.

“Only for the poultry, we probably wouldn’t have invested in a telehandler and instead worked away with a tractor and loader. However, now used to a dedicated loader, it would be near impossible to move back. It’s much faster at doing the work and much more nimble.

“The KT276 was a good machine but the KT316 is the perfect fit, size and performance wise. Everything about its design has been well thought out, for example the notch in the floor to improve access is a simple but effective. Access for maintenance is second to none, all fluid levels are easy checked and grease nipples are grouped for handiness. The build quality is top class too.

“It’s a gutsier machine on the road and in the yard. It is a bit harder on fuel, which one would expect with the increase in horsepower.

“We’d likely change it for another if it proves reliable in the coming years,” Stephen said.

The cab is well laid out and offers great visibility.

Downards machine is fitted on the smaller 20in wheel rims and Michelin Bibload tyres to keep its height low.

Likes

Physical size. Build quality.Performance.

Dislikes

Manual handbrake could be swapped for electric. Storage compartment door hinge.

The boom lowers well and sits flush with the bonnet to improve visibility.

Steven would rather if an electric handbrake was fitted over the manual version.

Spec

Engine: 2.9l Deutz (four cylinder).Horsepower: 112hp.Transmission: single-range hydrostatic.Travel speed: 40km/hTelescopic reach: 6m.Lift capacity: 3,100kg.Hydraulics: 109l/min flow rate.Tyres: 400/70 R20.Fuel tank capacity: 125l.List price: €124,000 plus VAT.

The telehandler being used to transport meal to creep feeders for dairy beef calves.

Steven alongside his son and father, Alex Downard.

Situated in the farming stronghold of Markethill, Co Armagh, Stephen Downard runs a dairy calf-to-beef enterprise with his brother Paul and father Alex, alongside working off-farm full-time. In 2012, Stephen and his wife, Carol ventured into the broiler poultry sector, which has expanded to six units containing up to 172,000 birds.

In search of a slightly more capable machine to replace his KT276, Stephen took delivery of the country’s first Kramer KT316 telehandler model earlier in the summer, following its debut at Balmoral Show in May. The machine in question sports all the optional bells and whistles, including Kramer’s Smart Attach, a hands-free, hydraulic, third service coupling system.

Background

Prior to the poultry, a tractor and front loader took care of all feeding and loader tasks on the farm. With a height restriction of 2.3m inside the poultry sheds, a more compact alternative to the tractor and front loader was needed. Aside from general farm work, a telehandler is used to clear litter out of the poultry sheds and load trucks.

In 2012, a used Manitou MLT 634 was bought an ran for six years, before switching to a Kramer KT276 in 2018.

Having felt that the Manitou was a little on the large side and getting on in age, Stephen decided to look at a replacement.

Local John Deere dealers, Johnston Gilpin were selling Kramer which he decided to enquire about. The most suitable model was the compact KT276, offering slightly less lift capacity at 2,7t and a 6m reach.

Manitou did offer an MLT 625 model but he felt the KT276 had the edge in terms of capacity, and so it was later purchased. It worked away trouble free until traded for the new model KT316 this summer.

With a better selection of 3,000kg/6m models on the market this time around, Stephen did enquire about Manitou’s MLT 630-115 V CP model. In the end, he stuck with Kramer based on a number of factors, including value for money and the reliability of his previous machine.

Steven feels the storage compartment under the steps should be hinged from either the left or right side to avoid damage in the event that it is not closed.

KT316

The KT316 is a brand-new compact model platform from Kramer to broaden its range. The newcomer slots between the smaller KT276 and KT356 models, suiting medium-sized livestock farms and situations where space is restricted like inside poultry sheds.

The KT316 is slightly larger than the KT276, measuring 2.15m high, 2.09m wide and 4.5m long in comparison to the KT276 with respective dimensions of 2.1m, 1.96m and 4.4m in the high cab version. This marginal increase made the KT316 an ideal fit for the Downards’ farm.

“Having come form a slightly larger machine originally, we missed the extra capacity when handling the shear grab and bales, etc. The guys at Kramer knew I was always after something a little bigger, and so they contacted me about the KT316. We were due to change our machine, at the time anyway,” Stephen outlined.

Engine and transmission

Underneath the bonnet, the KT316 offers more grunt. It is fitted with a 112hp, 2.9l Deutz engine, 109l/min hydraulic pump and a 40km/h transmission as standard.

In comparison, the KT276 was equipped with a 72hp Kohler engine, 103l/min hydraulics and a 20km/h transmission, as standard (40km/h option).

Stephen’s machine was fitted with the standard unit. The faster, 40km/h transmission in the KT316 is a huge benefit when travelling to different blocks of land, he said. To lower his machine a further 50-60mm, Stephen opted for 20in rims instead of the larger 24in.

With no shortage of dips and hollows around Markethill, Stephen said that the KT316, given its extra horsepower, is much more capable on hills and doesn’t die back as much on approach. As standard, there are three preset driving modes: power, eco and constant speed drive (CSD). It is also fitted with the reversible fan option, which Stephen noted is good, especially when working in the poultry sheds where a lot of dust tends to get pulled in. By opening the bonnet and removing the lower side panel, full access can be gained to the entire engine bay, a feature Stephen likes.

Access to the engine bay is super.

The Smart Attach headstock eliminates the need to exit the cab and manually connect third service hydraulic couplings.

Capacities

The KT316 has a maximum lift capacity of 3,100kg and a maximum reach of 5.83m. The main attachments used on the Downards’ farm include a 6ft shear grab, a 7ft bucket, pallet forks, a bale squeeze and a brush. The KT316 is equipped with a smart hydraulic system with pressure compensation, leaving it better suited for multitasking and making full use of the 109l/min flow. The Smart Attach third service quick-coupling system, removes the need to get in and out of the cab when connecting/disconnecting the shear grab.

Cab

Although cab dimensions are identical to the KT276, control layout and fit and finish has improved, Stephen feels. One new feature making entry and exit from the cab easier is the notched floor which allows better access to the step. The notch disappears once the door is closed.

Also fitted to the machine is the optional 7in display terminal. All relevant machine data is summarised on the home screen, while adjustments to machine parameters can be made on the dedicated screens and via the rotary dial.

From here, hydraulic flow can be finely tuned to the individual boom and headstock rams. Downards’ machine is equipped with a long list of other options, such as automatic bucket return, lifting and lowering height limiter functions, rear pickup hitch with dual-line hydraulic brakes and a rear-view camera system.

In terms of visibility from the cab, Stephen feels that is ahead of anything else he has sat in to date, particularly out across the bonnet. The machine is also kitted out with the full LED work light package, which the family rate highly.

The only minor critiques Stephen has regarding the cab was the storage box alongside the step. He feels that if it was hinged on the left or right then it would be better protected in the event it was accidentally left open. Another tweak, but also not a deal breaker, would be an electric handbrake over a manual handbrake.

Downards machine is equipped with a pickup hitch with rear spools and dual-line brakes.

The notch in the cab floor greatly improves access in and out of the cab.

The optional 7in terminal displays all machine information and parameter settings.

Verdict

With seven years’ experience running Kramer, Stephen is more than happy with the product and the backup.

“Only for the poultry, we probably wouldn’t have invested in a telehandler and instead worked away with a tractor and loader. However, now used to a dedicated loader, it would be near impossible to move back. It’s much faster at doing the work and much more nimble.

“The KT276 was a good machine but the KT316 is the perfect fit, size and performance wise. Everything about its design has been well thought out, for example the notch in the floor to improve access is a simple but effective. Access for maintenance is second to none, all fluid levels are easy checked and grease nipples are grouped for handiness. The build quality is top class too.

“It’s a gutsier machine on the road and in the yard. It is a bit harder on fuel, which one would expect with the increase in horsepower.

“We’d likely change it for another if it proves reliable in the coming years,” Stephen said.

The cab is well laid out and offers great visibility.

Downards machine is fitted on the smaller 20in wheel rims and Michelin Bibload tyres to keep its height low.

Likes

Physical size. Build quality.Performance.

Dislikes

Manual handbrake could be swapped for electric. Storage compartment door hinge.

The boom lowers well and sits flush with the bonnet to improve visibility.

Steven would rather if an electric handbrake was fitted over the manual version.

Spec

Engine: 2.9l Deutz (four cylinder).Horsepower: 112hp.Transmission: single-range hydrostatic.Travel speed: 40km/hTelescopic reach: 6m.Lift capacity: 3,100kg.Hydraulics: 109l/min flow rate.Tyres: 400/70 R20.Fuel tank capacity: 125l.List price: €124,000 plus VAT.

The telehandler being used to transport meal to creep feeders for dairy beef calves.

Steven alongside his son and father, Alex Downard.

SHARING OPTIONS