Loader and implement manufacturer, Quicke, has released a new range of Silocut implements.

The new attachment is a two-in-one unit. It acts as a shear grab for cutting silage from clamps and also splits bales while retaining the net/plastic, similar to what a number of Irish manufacturers offer.

The Swedish company is offering the range in three different models with various options. Suitable for tractor loaders, compact wheel loaders and mid-sized telehandlers, there are three sizes available: M+, L+ and XL+.

The Swedish company is offering the range in three different models with various options.

The Silocut M+ is available with replaceable bolt-on tines or with profile cut tuff tines welded in the carriage. Various accessories, such as bolt-on screens allow users to customise the implement. The Silocut L+ is available with forged or profiled cut “tufftines” but also a bucket to handle loose material. Meanwhile, the Silocut XL+ is the high-capacity model.

Suitable for tractor loaders, compact wheel loaders and mid-sized telehandlers, there are three sizes available; M+, L+ and XL+.

The Silocut M+ is available with replaceable bolt on tines or with profile cut tuff tines welded in the carriage.

The Silocut L+ and XL+ are available with a bale wrap handler as well as a push-out mechanism. Quicke says the bale wrap handler makes it possible to split, grab the net/wrap and retain it, meaning there’s no need to remove the wrap by hand. The profile cut tuff tine versions can also be equipped with a push-out mechanism to ease unloading into diet feeders or other areas where space is limited.

Both the Silocut L+ and XL+ are available with a bale wrap handler as well as a push out mechanism.

Silocut L+ is available with forged or profiled cut “tufftines” but also a bucket to handle loose material.

Quicke says the bale wrap handler makes it possible split, grab the net/wrap and retain it, meaning there’s no need to remove the wrap by hand.

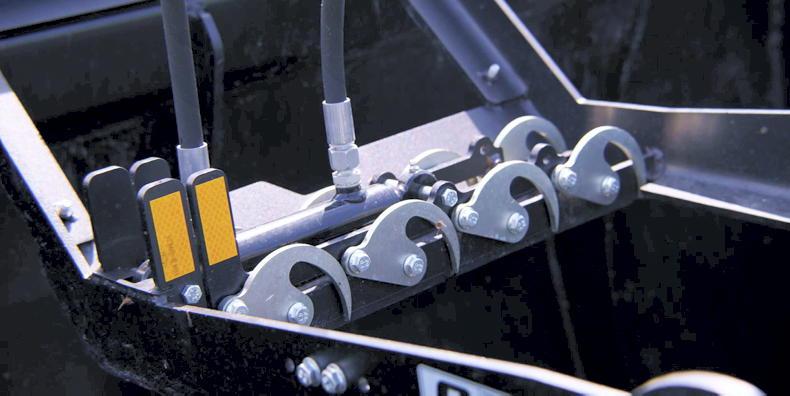

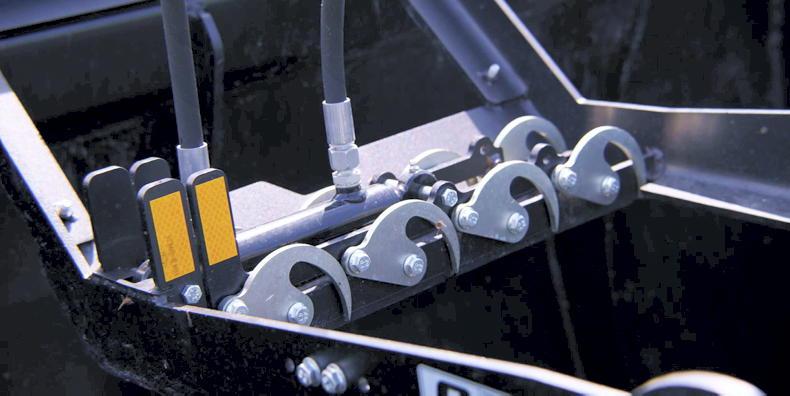

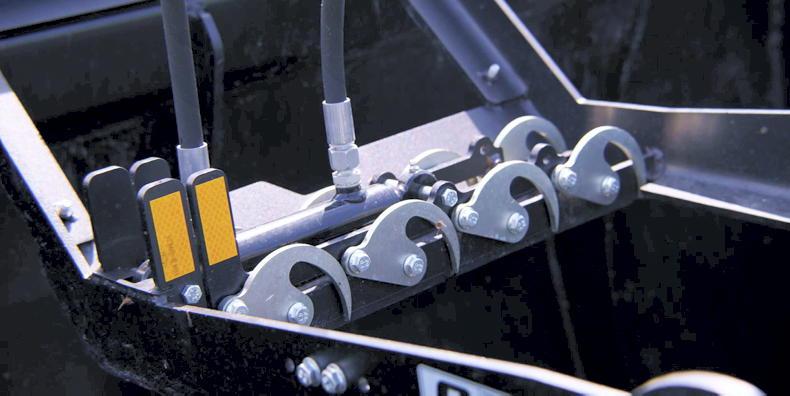

Quicke has also released a new sequencer valve, which allows users combine work with two independent hydraulic functions on the implement with just a third service. This valve allows the oil to divert to the bale wrap handler when the cut is completed, ensuring the bale is completely split.

Loader and implement manufacturer, Quicke, has released a new range of Silocut implements.

The new attachment is a two-in-one unit. It acts as a shear grab for cutting silage from clamps and also splits bales while retaining the net/plastic, similar to what a number of Irish manufacturers offer.

The Swedish company is offering the range in three different models with various options. Suitable for tractor loaders, compact wheel loaders and mid-sized telehandlers, there are three sizes available: M+, L+ and XL+.

The Swedish company is offering the range in three different models with various options.

The Silocut M+ is available with replaceable bolt-on tines or with profile cut tuff tines welded in the carriage. Various accessories, such as bolt-on screens allow users to customise the implement. The Silocut L+ is available with forged or profiled cut “tufftines” but also a bucket to handle loose material. Meanwhile, the Silocut XL+ is the high-capacity model.

Suitable for tractor loaders, compact wheel loaders and mid-sized telehandlers, there are three sizes available; M+, L+ and XL+.

The Silocut M+ is available with replaceable bolt on tines or with profile cut tuff tines welded in the carriage.

The Silocut L+ and XL+ are available with a bale wrap handler as well as a push-out mechanism. Quicke says the bale wrap handler makes it possible to split, grab the net/wrap and retain it, meaning there’s no need to remove the wrap by hand. The profile cut tuff tine versions can also be equipped with a push-out mechanism to ease unloading into diet feeders or other areas where space is limited.

Both the Silocut L+ and XL+ are available with a bale wrap handler as well as a push out mechanism.

Silocut L+ is available with forged or profiled cut “tufftines” but also a bucket to handle loose material.

Quicke says the bale wrap handler makes it possible split, grab the net/wrap and retain it, meaning there’s no need to remove the wrap by hand.

Quicke has also released a new sequencer valve, which allows users combine work with two independent hydraulic functions on the implement with just a third service. This valve allows the oil to divert to the bale wrap handler when the cut is completed, ensuring the bale is completely split.

SHARING OPTIONS