The College of Agriculture, Food and Rural Enterprise (CAFRE) recently constructed new facilities on their Greenmount Hill farm at Glenwherry, Co Antrim which have the potential to accommodate up to 750 ewes.

Prior to the construction of the new shed the flock of 1,100 ewes, run on the 1,000ha farm, were housed in three different facilities, with sheep handling facilities located elsewhere. This was a situation that was unmanageable for a demonstration farm. The farm itself is predominantly comprised of unimproved grassland and heather moorland.

The new shed is self-contained with group pens, individual lambing pens and an impressive handling facility all under the one roof, greatly improving the management of ewes for those working on the farm.

The shed

The expansive shed is an impressive 1,870m² measuring 72m long by 26m wide. A single (5m wide) feed passage provides access to the 17 pens. Of the 17 pens, 15 measure 8m x 6.1m and have capacity for 44 ewes, the remaining two pens are 6m x 6m and provide space for 33 ewes each. The dimensions provide each ewe with 1.1m² of accommodation. The shed measures 3.8m high at the eaves and provides sufficient ventilation to the shed with a high number of stock, without any draughts developing. Four separate slurry storage tanks are in place in the shed, to facilitate mixing. Three of the tanks are 1.2m deep while the fourth is 1.8m due to the slope of the land that would have otherwise required additional infilling. An internal pumping system is in place in the tanks to aid agitation.

Lambing pens

The shed contains 56 individual fixed lambing pens with the space available to construct a further 28 temporary pens in the handling area during the busy lambing period. Lambing pens measure 1.5m x 1.5m. All pens are supplied by water through a 150mm pipe which is regulated by a ball valve at one end. The reason this pipe works so well is that the gates of the lambing pens were fabricated with brackets to hold this pipe securely in place, ensuring it is level at all times. Two channels run the length of the lambing pens which will collect any fluids, in a bid to keep the lambing pens as dry as possible. Different cladding was used on each side of the shed to ensure adequate ventilation throughout but to also ensure that it was not too cold for newborn lambs. Traditional spaced boarding was used on one side with Yorkshire cladding over the spaced boarding on the other, this limits the strong winds that would otherwise affect the lambing pens.

Slipping

All of the sheep pens are fitted with plastic slats with a knobbed surface which helps reduce ewes slipping. The shed is very well designed with sliding gates between each pen. These gates allow for ewes to move down through the pens of the shed to one end, here they can access the exterior passageways where they can move along to the handling unit or the lambing pens.

Going through the slatted pens as opposed to travelling down the feed passage ensures that passages remain clean for fodder.

These type of gates are also much easier on farmers as it reduces the need to be climbing gates between pens. Similar-type gates could be an option in calf housing where space is limited.

Each pen is also fitted with an animal-operated drinker which provides fresh water on demand. All drinkers in the shed are connected to a system which monitors the water temperature which will cause the water heating unit to kick in, in the case of freezing temperatures which can be a big issue on this farm due its elevated location.

Feeding

Pens are designed so that ewes can all feed from the large pens along the central passage at one time. Ewes each have a feed space of 18cm. Feed gates are fitted with a hinged barrier which means that ewes feeding can be controlled.

These barriers also aid a farmer where a diet feeder is to be used, as a farmer can feed along both sides of the passage before allowing ewes access to the material. The central rail on the gates is also adjustable to suit the size of the sheep in the pens.

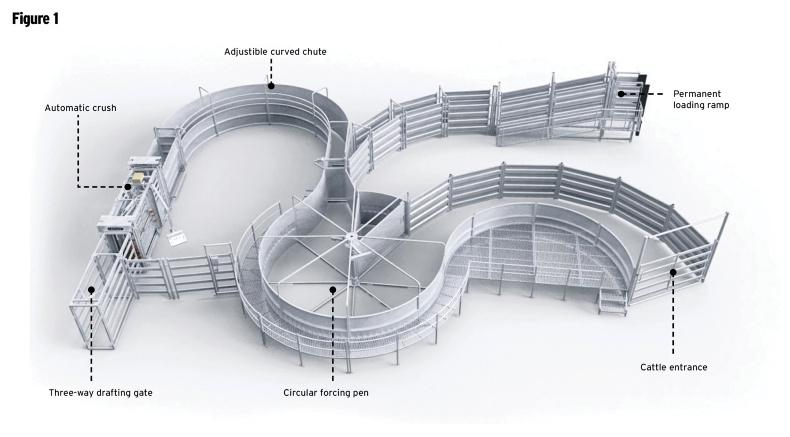

Handling units

The handling unit is designed to aid the management of such a large flock and comprises a long narrow collecting yard, a circular forcing pen, and a long handling chute.

It is laid out in a U-shape to complement the natural behaviour of sheep. Sheep will move from the circular forcing pen and up the chute before they come to the combi-clamp which can be used to hold sheep while dosing or dagging, for example.

A drafting unit is also in place as part of the handling unit which allows for the automatic drafting by way of weight or by sex of the lamb. This allows the quick drafting of ewe and wether lambs.

A large capacity footbath is also located within the handling facilities. This is divided into two separate baths which are separated by vertical lifting guillotine gates.

This allows between 40 and 50 ewes to be held in the footbath at any one time. A pipe connecting the baths to the slurry storage tanks means that both baths can be easily emptied.

The entire shed is designed with the handling unit in mind with passageways around the perimeter of the shed to ensure quick movement of stock.

All of the pens can also act as holding pens capable of accommodating the entire flock.

SHARING OPTIONS