Cappoquin Estate farm, home to the Tintur Holsteins herd, recently held an open day to showcase the five DeLaval V300 robotic milking machines recently installed on the farm. Big crowds turned out on the day to view the system in action.

The farm is not your conventional grass-based dairy operation, with high-yielding cows housed all-year-round. The decision to house the herd full-time was made in 2016.

Farm manager Roger Barkley spoke about the system on the day.

“The main reason behind going robotic was labour. We just couldn’t get it. The staff we did have were working 12 to 13 hours per day, with milking taking seven to eight hours and by the time we included wash-ups, the majority of our day was spent milking cows or tidying up after cows.

“Another reason is that the herd is high-yielding – ideally, they want to be milked three times a day,” Roger explained.

“Whenever we outgrew the parlour we still had room for expansion so we decided that instead of working workers harder we would make the cows work for themselves and went down the robotic route,” he said.

The initial target is to have 275 cows milking on the robots 365 days of the year, according to Roger.

The herd is currently averaging 9,600 litres at 765kg of milk solids, with cows being fed 2.5t/year. Calving interval for the herd is 404 days.

The herd is split between high-yielders and low-yielders with separate cubicles and feeding facilities for each group. All cows have access to the five robots and will be drafted to their designated group after milking.

Low-yielding cows – doing less than 36 litres/day – are fed on a predominantly grass-based diet while the high-yielders only receive 5kg to 6kg DM of grazed grass per day, with the remainder of the diet being made up with TMR.

Original targets

The original aim when going with five robots was 55 cows/robot, but this was based on the old model and with the V300 Roger expects to be able to push this to between 65 and 70 cows per robot.

Listen to "DeLaval showcase five robot farm" on Spreaker.

“We are targeting fairly high yields. We hope to hit about 10,500 litres, but we are also targeting solids. We hope to be at 800kg of solids sold per cow over the next two years. The shed is capable of holding 286 cows with feed space for every cow but with the robotic system I could see us being fit to push this to over 300 cows.

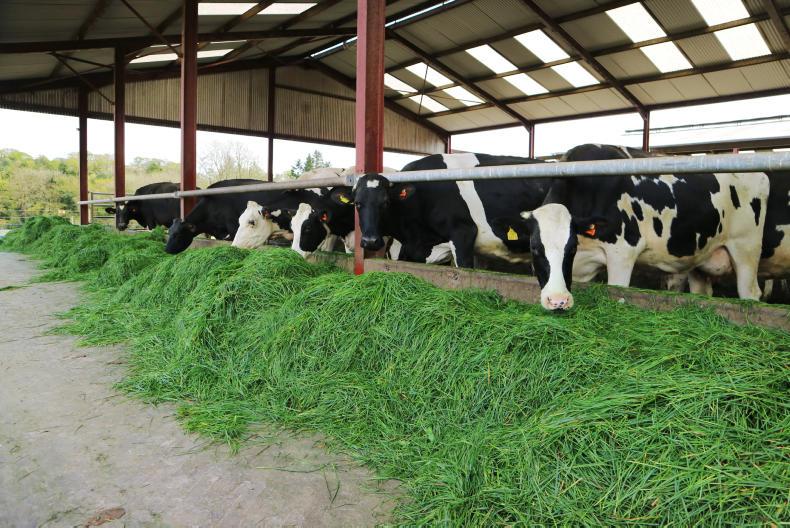

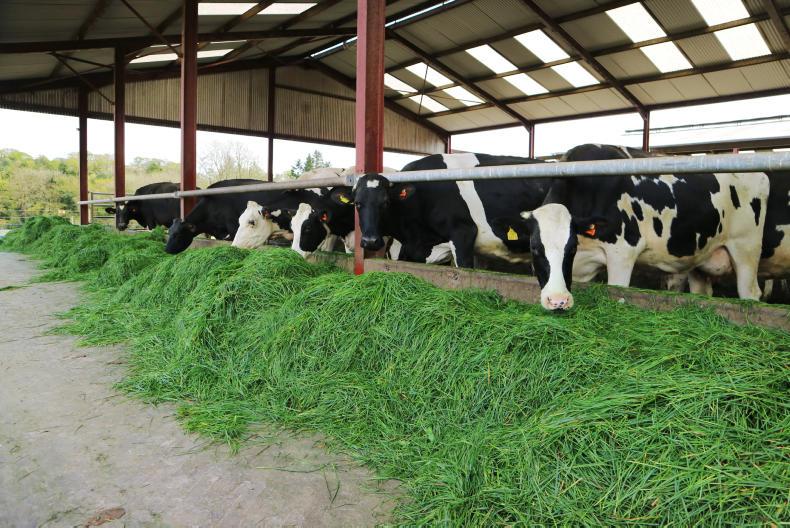

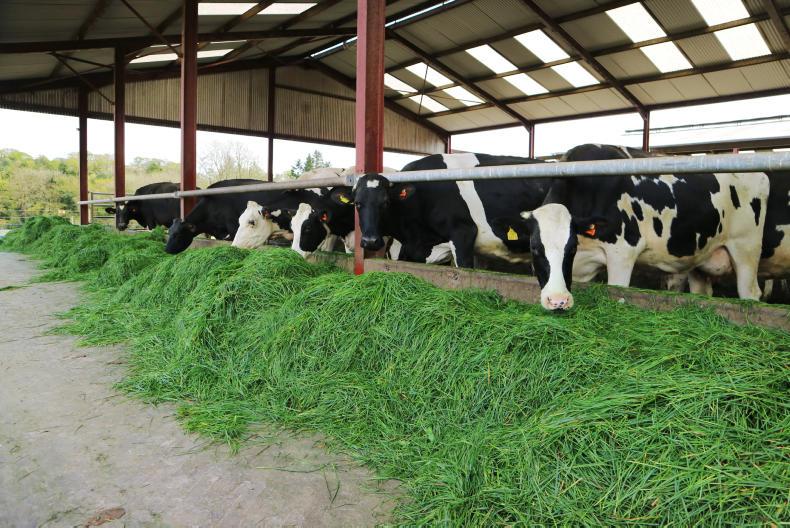

Low-yielding cows are fed a predominantly grass-based diet.

“We have been breeding the type of cow that we have been looking for over the past four years. We have a high standard output but we have heifers coming through doing 900kg of milk solids in their first lactation and still calving down at a 365-day calving pattern. I think the potential is in the black and white breed to deliver. I have faith in the breed.”

Feed-first system

The farm operates a feed-first cow flow system where a cow will be guided to the feed face before they are then directed towards the robot. When cows exit the robots they have to pass through the drafting gate once more. This has advantages in that it ensures that a cow will stay standing for 10 to 15 minutes, which allows the teat ends to close up.

The DeLaval advisers recommended having a waiting area of five cows per robot, which would mean a waiting area of 25 cows for this five-robot farm.

All robots are located in a line, with a small lean-to shed constructed over them. The robots are located side-on to the holding area.

The five robots are situated side on adjoining each other.

“I think it was a bigger challenge for the people than the cows. The cows settled in after four or five days. We had more issues getting them to go through the automatic guided flow system than we had to actually get them to go through the robots,” Roger said.

“They had to learn to slow down going through the drafting system and allow the gates to change but that’s just the system we had installed.

“Labour and teaching us what to do with the changeover was the hardest part. The biggest change that we have had to come to terms with is the routine of cows. If you feed her too much she doesn’t flow. It’s a bit like the grass-based systems – you have to keep them working as opposed to you having to work them,” Roger explained.

“If you get the intakes right they flow right and everything goes nicely. If you get the intakes wrong, they are not hungry so they lie down and sleep all day. So that does slow the whole thing down. We try and vary the feeding a bit as it helps to keep cows moving.

“We have modified ourselves over the past six months but every day is a school day and there is great potential in the system.”

Cows move through slatted passageways back to the drafting gates.

High-yielding cows will be fed grass between 11am and 2pm and will then receive their TMR diet at 6.30pm, while the low-yielding cows will get grass in the morning.

Cows are currently averaging 2.6 milkings per day and 15kg/milking, according to Roger.

Roger admits that it is not a system that would suit everyone. “I don’t tell anybody what system suits their farm. I’m not into the line of saying one system for everybody. It’s up to the farmers to make the decision on what suits their own place and visit plenty of farms to see what everyone is doing. I just prefer the system we have for the cow type we have.

“There is a lot of potential in farms just modifying the system to suit the farm.”

Investment

Going down the robotic route is a big investment for any farmer.

As a rough guide for a new entrant starting out, the V300 would work out at approximately €150,000 excluding VAT for the first robot. This would include all drafting gates, pumps, the bulk tank and all associated fittings. Any subsequent V300 would cost between €80,000 and €90,000 excluding VAT. For a two-robot farm, this would equate to approximately €115,000 excluding VAT per robot.

Roger Barkley, farm manager of the Tintur Holsteins.

The V300 has seen the capacity that the robot can cater for increase from 55 cows to between 65 and 70, but again this will depend on what type of cow you have. The robot doesn’t measure fat and protein but it can measure somatic cell count. It also has a mastitis detection index that will alert you to possible cases of mastitis.

The new system comes with a teat preparation system where a cup attaches on to each teat separately prior to milking and cleans the teat.

DeLaval claims that this speeds up the milking process. However, the main advantage of the new system, they claim, is the quicker and more accurate teat attachment which they say means the robot has the potential to milk over 2,500kg of milk per day.

Cappoquin Estate farm, home to the Tintur Holsteins herd, recently held an open day to showcase the five DeLaval V300 robotic milking machines recently installed on the farm. Big crowds turned out on the day to view the system in action.

The farm is not your conventional grass-based dairy operation, with high-yielding cows housed all-year-round. The decision to house the herd full-time was made in 2016.

Farm manager Roger Barkley spoke about the system on the day.

“The main reason behind going robotic was labour. We just couldn’t get it. The staff we did have were working 12 to 13 hours per day, with milking taking seven to eight hours and by the time we included wash-ups, the majority of our day was spent milking cows or tidying up after cows.

“Another reason is that the herd is high-yielding – ideally, they want to be milked three times a day,” Roger explained.

“Whenever we outgrew the parlour we still had room for expansion so we decided that instead of working workers harder we would make the cows work for themselves and went down the robotic route,” he said.

The initial target is to have 275 cows milking on the robots 365 days of the year, according to Roger.

The herd is currently averaging 9,600 litres at 765kg of milk solids, with cows being fed 2.5t/year. Calving interval for the herd is 404 days.

The herd is split between high-yielders and low-yielders with separate cubicles and feeding facilities for each group. All cows have access to the five robots and will be drafted to their designated group after milking.

Low-yielding cows – doing less than 36 litres/day – are fed on a predominantly grass-based diet while the high-yielders only receive 5kg to 6kg DM of grazed grass per day, with the remainder of the diet being made up with TMR.

Original targets

The original aim when going with five robots was 55 cows/robot, but this was based on the old model and with the V300 Roger expects to be able to push this to between 65 and 70 cows per robot.

Listen to "DeLaval showcase five robot farm" on Spreaker.

“We are targeting fairly high yields. We hope to hit about 10,500 litres, but we are also targeting solids. We hope to be at 800kg of solids sold per cow over the next two years. The shed is capable of holding 286 cows with feed space for every cow but with the robotic system I could see us being fit to push this to over 300 cows.

Low-yielding cows are fed a predominantly grass-based diet.

“We have been breeding the type of cow that we have been looking for over the past four years. We have a high standard output but we have heifers coming through doing 900kg of milk solids in their first lactation and still calving down at a 365-day calving pattern. I think the potential is in the black and white breed to deliver. I have faith in the breed.”

Feed-first system

The farm operates a feed-first cow flow system where a cow will be guided to the feed face before they are then directed towards the robot. When cows exit the robots they have to pass through the drafting gate once more. This has advantages in that it ensures that a cow will stay standing for 10 to 15 minutes, which allows the teat ends to close up.

The DeLaval advisers recommended having a waiting area of five cows per robot, which would mean a waiting area of 25 cows for this five-robot farm.

All robots are located in a line, with a small lean-to shed constructed over them. The robots are located side-on to the holding area.

The five robots are situated side on adjoining each other.

“I think it was a bigger challenge for the people than the cows. The cows settled in after four or five days. We had more issues getting them to go through the automatic guided flow system than we had to actually get them to go through the robots,” Roger said.

“They had to learn to slow down going through the drafting system and allow the gates to change but that’s just the system we had installed.

“Labour and teaching us what to do with the changeover was the hardest part. The biggest change that we have had to come to terms with is the routine of cows. If you feed her too much she doesn’t flow. It’s a bit like the grass-based systems – you have to keep them working as opposed to you having to work them,” Roger explained.

“If you get the intakes right they flow right and everything goes nicely. If you get the intakes wrong, they are not hungry so they lie down and sleep all day. So that does slow the whole thing down. We try and vary the feeding a bit as it helps to keep cows moving.

“We have modified ourselves over the past six months but every day is a school day and there is great potential in the system.”

Cows move through slatted passageways back to the drafting gates.

High-yielding cows will be fed grass between 11am and 2pm and will then receive their TMR diet at 6.30pm, while the low-yielding cows will get grass in the morning.

Cows are currently averaging 2.6 milkings per day and 15kg/milking, according to Roger.

Roger admits that it is not a system that would suit everyone. “I don’t tell anybody what system suits their farm. I’m not into the line of saying one system for everybody. It’s up to the farmers to make the decision on what suits their own place and visit plenty of farms to see what everyone is doing. I just prefer the system we have for the cow type we have.

“There is a lot of potential in farms just modifying the system to suit the farm.”

Investment

Going down the robotic route is a big investment for any farmer.

As a rough guide for a new entrant starting out, the V300 would work out at approximately €150,000 excluding VAT for the first robot. This would include all drafting gates, pumps, the bulk tank and all associated fittings. Any subsequent V300 would cost between €80,000 and €90,000 excluding VAT. For a two-robot farm, this would equate to approximately €115,000 excluding VAT per robot.

Roger Barkley, farm manager of the Tintur Holsteins.

The V300 has seen the capacity that the robot can cater for increase from 55 cows to between 65 and 70, but again this will depend on what type of cow you have. The robot doesn’t measure fat and protein but it can measure somatic cell count. It also has a mastitis detection index that will alert you to possible cases of mastitis.

The new system comes with a teat preparation system where a cup attaches on to each teat separately prior to milking and cleans the teat.

DeLaval claims that this speeds up the milking process. However, the main advantage of the new system, they claim, is the quicker and more accurate teat attachment which they say means the robot has the potential to milk over 2,500kg of milk per day.

SHARING OPTIONS