Building a handling unit can be a significant investment on any farm. However, ensuring the safety of the farmer and livestock should be a priority, according to Colin Tyner from Shilleagh, Co Wicklow.

Colin operates a suckler herd of more than 100 continental cows, with all progeny being brought through to slaughter on the farm.

Due to the high livestock numbers, Colin said it was vital to ensure the unit could handle large volumes of stock quickly and safely.

William Conlon visited a cattle handling unit in Wicklow, built to make cattle handling safer and more efficient https://t.co/1zl6bRcmE2 pic.twitter.com/HpPCBUrYgk

— Farmers Journal (@farmersjournal) December 29, 2016

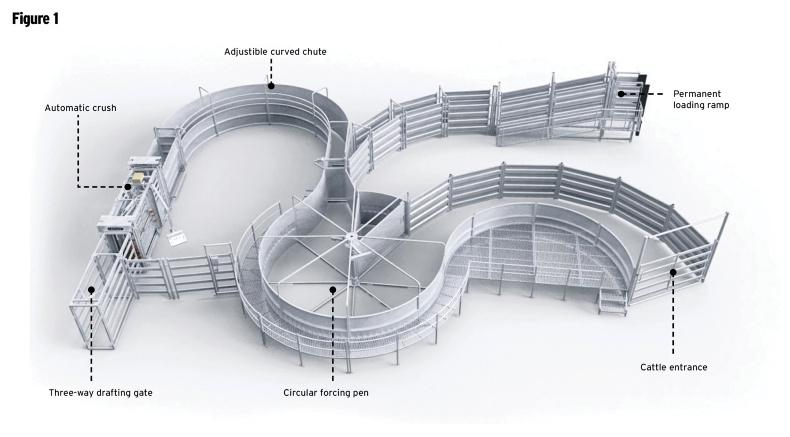

The handling unit is designed so that cattle are continually moving in a U-shape between holding areas and the race itself. This is because cattle have a tendency to return in the direction from which they came.

The handling unit is made up of three large holding pens which allows high numbers of stock to be held close to the race, allowing for efficient throughput of cattle for handling. A semicircular carousel with a diameter of 7.6m is used to drive cattle into the race. The carousel is fitted with an anti-backing gate to ensure operator safety when trying to push cattle towards the race mouth.

According to Colin, up to 150 cattle can be easily held in the yard for handling at any one time. This greatly reduces the time taken to carry out any jobs such as dosing or injecting as all cattle can be assembled beforehand. The race itself is 9.6m long and can hold approximately five cows at a time.

Cattle enter the holding pens from a yard where all the cattle housing is located. They can be easily moved from one pen to the next until they reach the race. The holding pens are designed to be relatively narrow to ensure that cattle will naturally move forwards and so that they do not have sufficient space to turn back on the farmer.

There is a walkway running alongside the race that cattle cannot enter. This allows safe access for the farmer working with the cattle in the race without coming in contact with cattle in the holding pen. Colin is also in the process of installing a power source in this walkway so that tail clipping, among other tasks, can be carried out.

The use of a carousel to funnel cattle into the race is becoming a popular option for farmers installing a new handling unit. The ease with which cattle can be pushed towards the mouth of the race reduces stress on both the animal and farmer. The carousel is fitted with notches all along the top bar to prevent the gate from swinging back if an animal pushes against it, ensuring the safety of the farmer. The curved entrance to the race is lined with stock board. This is done so that cattle don’t get distracted or startled by activity around the race. Stock board is also fitted along one side of the race to aid cattle flow.

A guillotine gate is in place at the back of the crush, which is the safer option when compared with the conventional swinging gate.

All of the concrete in the yard was grooved when it was laid to ensure cattle would not slip and injure themselves or others.

The grooves are deep enough to provide cattle with good underfoot grip but also shallow enough to allow the yard to be easily cleaned.

Safety

Colin says his main motivation for constructing this handling unit was farmer safety after close calls in the past when testing cattle. “I was testing cattle with my wife, Janet, and a heifer broke back as we were herding them towards the race. As it was going by Janet, it kicked out a leg and hit her in the arm. It threw her in the air and when she landed she went flying across the yard. I was watching it in slow motion and how she didn’t break her back or her arm I’ll never know. If the kick was 6in higher it would have got her in the side of the head and she would have been killed.”

Cost

All the steelwork and the plans for the handling unit were provided by Condon Engineering and cost a total of €9,560 including VAT. The concrete cost a total of €6,750 including VAT while total labour costs accumulated to €4,500 including VAT. This gives a total cost of €20,810 including VAT.

Colin hopes to claim approximately €5,000 back through VAT, leaving a total cost of the handling unit at approximately €15,810. Colin did not apply for a TAMS grant on the project as he believed that the extra requirements and specifications would negate any potential financial savings from getting the grant.

SHARING OPTIONS