Three different parlours were examined as part of a Teagasc Clonmel open day held last week. With many farmers in the area considering building new milking facilities or extending existing machines, the purpose of the day was to present farmers with the different options when deciding to expand.

A lot of factors will dictate what type of parlour you decide to go with including site location, number of units, cow flow, labour, working conditions, costings and scope for further expansion.

This week, a 20-unit DeLaval parlour with 2ft 6in centres will be examined. Over the next few weeks we will look at a 16-unit Dairymaster parlour with 2ft 2in centres and a farm with two Lely robotic automated milking units.

20-unit Delaval parlour

This parlour was constructed on Bill Carroll’s farm at Gurteen, Kilsheelan, Co Tipperary. The farm is currently milking 200 cows. However, the plan is to push this to 300 in the coming years. The farm is leased out in a long-term lease and as with any long-term lease, every investment must be scrutinised to ensure it is viable.

When the new parlour was constructed it was decided to build it in an existing shed on the farm. A protected structure to the front of the shed and an existing slurry tank to the back gave a limited amount of space for the parlour to be constructed in.

Pat Clarke, dairy specialist with Teagasc, spoke on the day about the vital issue of cow flow when constructing a new parlour. He outlined how poor cow flow can lead to issues with lameness and high cell count among other things.

According to Pat, the majority of problems arise from cows going in and out of the parlour and so it is vital that it is correctly planned out at the design stage. One of the key issues highlighted on this farm was the potential cow flow issues that may arise as the herd expands.

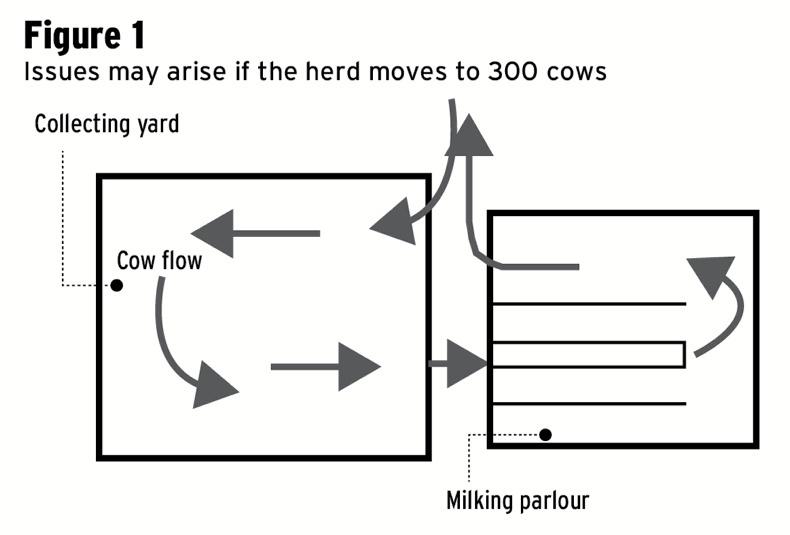

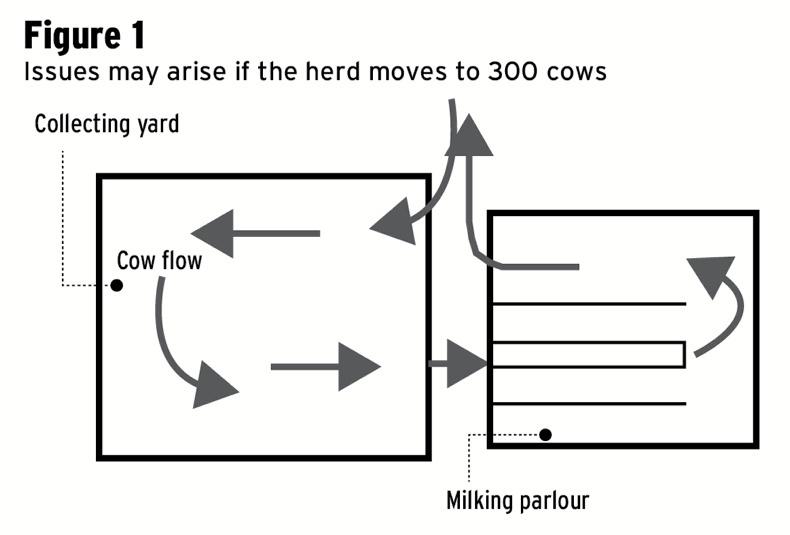

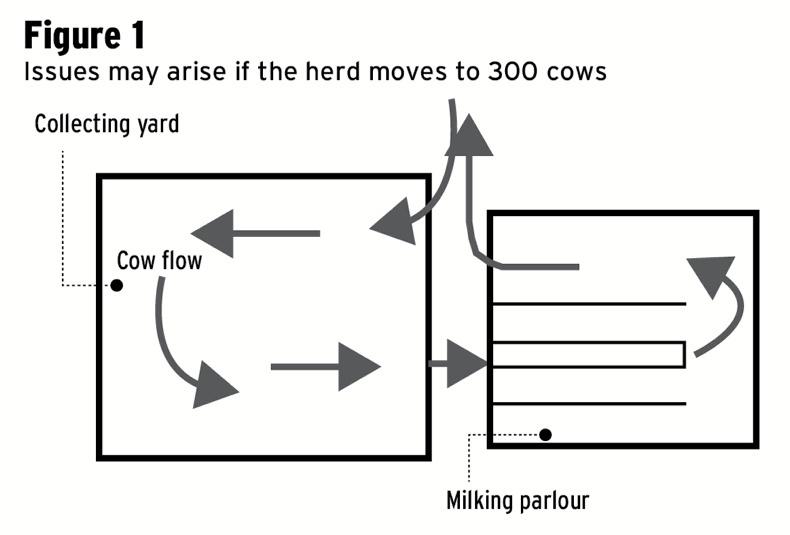

As seen in Figure 1, the collecting yard is located straight out from the parlour, giving cows a straight run into the parlour, which is recommended. The only concern in relation to this setup is that cows must make a 90-degree turn into the collecting yard at which point they have to make a U-turn to align themselves to enter the parlour.

While the collecting yard is big enough to allow the current herd of 200 cows to turn comfortably, problems may arise if the herd is expanded to 300 cows. Ideally, cows would enter the collecting yard from the rear so that they do not have to turn in the collecting yard, and this may be looked at as the herd expands. Pat stressed that the collecting yard should be large enough to provide every cow with 1.5m2 of space. The yard should also be designed to hold all of the herd with no cows in the parlour.

Planning

When planning a new parlour, it is important to assess what direction your cows will be coming in from paddocks most of the time and to locate the parlour to suit this. Pat’s final advice was to keep the parlour independent of other activities on the farm. This is especially important for larger herds, as it will mean the yard will not have to shut down for other employees at milking.

Farmers should also not be afraid to move the parlour to a greenfield site as the majority of old farmyards are not designed for large herds.

20-unit parlour.2ft 6in centres.Duovac vacuum system.Straight feed trough with adjustable breast rail.Zig-zag back rail.Scissors gates at end of parlour. Read More

Weekly podcast: Varadkar on farming's challenges and IFA liquid milk protest

Design your livestock handling unit with safety in mind

Three different parlours were examined as part of a Teagasc Clonmel open day held last week. With many farmers in the area considering building new milking facilities or extending existing machines, the purpose of the day was to present farmers with the different options when deciding to expand.

A lot of factors will dictate what type of parlour you decide to go with including site location, number of units, cow flow, labour, working conditions, costings and scope for further expansion.

This week, a 20-unit DeLaval parlour with 2ft 6in centres will be examined. Over the next few weeks we will look at a 16-unit Dairymaster parlour with 2ft 2in centres and a farm with two Lely robotic automated milking units.

20-unit Delaval parlour

This parlour was constructed on Bill Carroll’s farm at Gurteen, Kilsheelan, Co Tipperary. The farm is currently milking 200 cows. However, the plan is to push this to 300 in the coming years. The farm is leased out in a long-term lease and as with any long-term lease, every investment must be scrutinised to ensure it is viable.

When the new parlour was constructed it was decided to build it in an existing shed on the farm. A protected structure to the front of the shed and an existing slurry tank to the back gave a limited amount of space for the parlour to be constructed in.

Pat Clarke, dairy specialist with Teagasc, spoke on the day about the vital issue of cow flow when constructing a new parlour. He outlined how poor cow flow can lead to issues with lameness and high cell count among other things.

According to Pat, the majority of problems arise from cows going in and out of the parlour and so it is vital that it is correctly planned out at the design stage. One of the key issues highlighted on this farm was the potential cow flow issues that may arise as the herd expands.

As seen in Figure 1, the collecting yard is located straight out from the parlour, giving cows a straight run into the parlour, which is recommended. The only concern in relation to this setup is that cows must make a 90-degree turn into the collecting yard at which point they have to make a U-turn to align themselves to enter the parlour.

While the collecting yard is big enough to allow the current herd of 200 cows to turn comfortably, problems may arise if the herd is expanded to 300 cows. Ideally, cows would enter the collecting yard from the rear so that they do not have to turn in the collecting yard, and this may be looked at as the herd expands. Pat stressed that the collecting yard should be large enough to provide every cow with 1.5m2 of space. The yard should also be designed to hold all of the herd with no cows in the parlour.

Planning

When planning a new parlour, it is important to assess what direction your cows will be coming in from paddocks most of the time and to locate the parlour to suit this. Pat’s final advice was to keep the parlour independent of other activities on the farm. This is especially important for larger herds, as it will mean the yard will not have to shut down for other employees at milking.

Farmers should also not be afraid to move the parlour to a greenfield site as the majority of old farmyards are not designed for large herds.

20-unit parlour.2ft 6in centres.Duovac vacuum system.Straight feed trough with adjustable breast rail.Zig-zag back rail.Scissors gates at end of parlour. Read More

Weekly podcast: Varadkar on farming's challenges and IFA liquid milk protest

Design your livestock handling unit with safety in mind

SHARING OPTIONS