A large calf shed was completed in 2015 on the farm of Hugh Harbison, who farms with the help of his father Thomson, near Aghadowey, Coleraine, Co Derry. A herd of approximately 150 cows begins to calve down in early September. The farm operates a block autumn-calving system, with 75% of cows calving in the first six weeks and all cows calving within 12 weeks.

The shed has the capacity to hold approximately 100 calves at any one time and was designed in-house.

The shed is uniquely designed to suit the homemade calf feeder and while not a conventional design, it is working very well with three batches of calves having moved through the shed so far.

“The shed was built around the feeder, which is maybe something a little different. We had looked at buying a 35-calf teat feeder, but they were coming in at about £5,000 so we decided to make our own one instead,” according to Hugh. “It worked out at a fraction of the price.”

Unique design

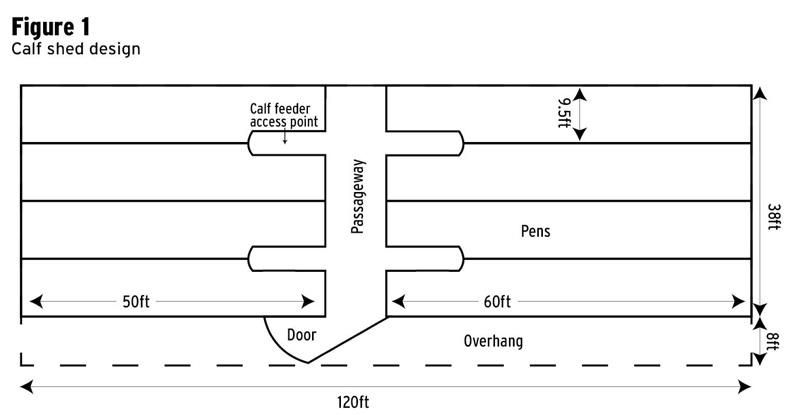

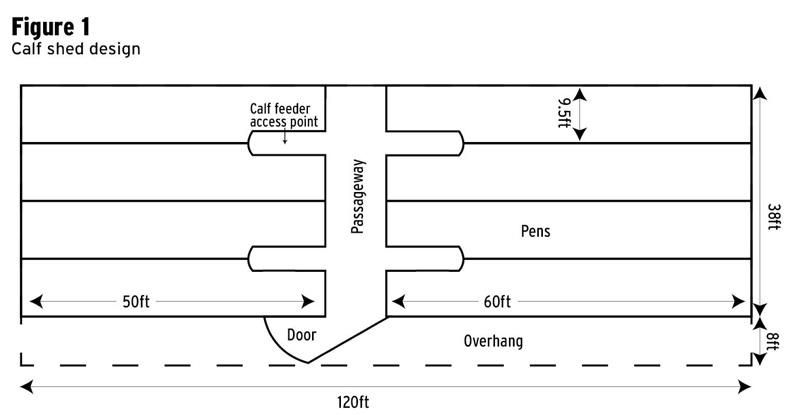

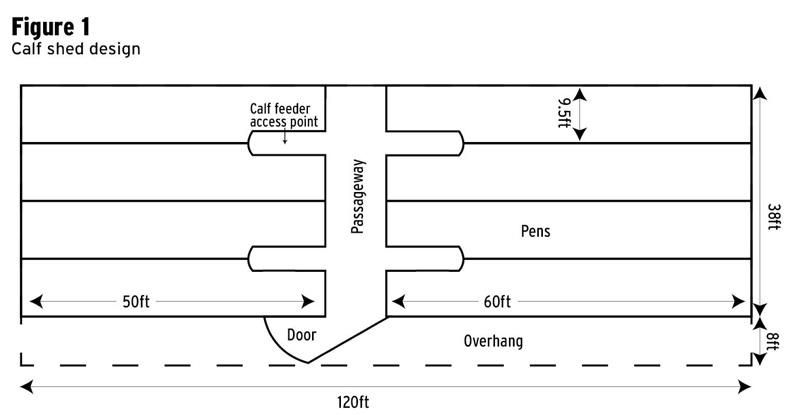

The shed is approximately 120ft long and 38ft wide. It is made up of six spans of 20ft. An 8ft overhang is also present along the front of the shed.

The shed is laid out in eight long pens, which are each capable of holding approximately 12 to 15 calves. Smaller groups may be kept for younger calves.

Due to the layout of the shed, four of the pens are about 10ft longer than the other four pens. However, there is still ample lying space for all calves in the pens. Feeding space is the dictating factor.

The shed is designed that two pens of calves can be fed at the one time to allow for quicker feeding. The portable calf feeder is rolled into the semi-oval shape that is left between pens. Access to feed calves is provided by a door along the side of the shed.

“The design means that one man can feed over 100 calves in the shed in about 25 minutes and that about 30 calves can drink around the feeder together, which is important,” according to Hugh.

The shed is divided into eight long pens, which will hold between 10 and 15 calves, depending on the age. Feeding and bedding

Pens will be bedded with straw towards the back of the pen and left clean nearer the feeding area. Sliding doors are in place at both ends of the shed to allow for ease of access for cleaning out of pens.

The interior layout of the shed can be completely changed as calves get older to allow a silage-based diet to be fed. All penning can be lifted out to allow calves access to the front of the shed.

A large straw layback area is still left, with the front area used for feeding. Flaps run all along the front of the shed which can be opened up to allow access to the wooden feed troughs that are in place.

The floor of the shed slopes towards a small 4ft-deep slatted tank, which runs along the front of the shed. The tank is fitted with pig slats, which have smaller slits that suit young calves. This tank predominantly collects dirty water.

The door positioned along the front of the shed can also be closed to provide additional feed space.

Older calves will be moved nearer the front of the shed and given access to silage, while younger calves will be kept in the back pens and given a milk-based diet until they are old enough.

All pens are fitted with water troughs, with water piped in above the pens to allow for easy removal when smaller pens are not being used.

Meal troughs are also in place in the pens. Four hay racks are positioned in the shed, with each rack servicing two pens.

Small storage lofts are in place inside the sliding doors along the back of the shed. These are used to store straw and hay for the calves.

Cleaning out

There is a sliding door in place at either end of the shed. On one side of the shed, the door is positioned along the back of the shed, while on the other side it is along the front of the pen. This means that it is very easy to get in with a tractor to clean out all pens in the shed.

The shed is lined front and back with spaced boarding. “We had looked at the Yorkshire boarding, but I thought it was just a little bit tight and might not let enough air through, so we went with the spaced boarding,” Hugh said.

Good airflow in calf sheds is vital to dilute and remove bacteria, moisture and gases from the air around calves. The aim is to ensure a continuous movement of fresh air through the shed.

Natural ventilation is the most common form in Ireland through a combination of the stack effect and wind. The effects of the stack effect are limited in calf houses, as large amounts of heat are not produced by the calves.

It is also vital to avoid draughts on calves, which can be caused by excessive air movement. The high roof ensures that there is a large cubic capacity, which helps to reduce the disease pressure on calves, as bacteria can rise away from calf height.

“The shed has been first-class since we put it up, with three batches of calves having gone through it to date,” according to Hugh.

Cost

The total cost of the project came to approximately £30,000, which works out at a cost of £300/calf.

A large calf shed was completed in 2015 on the farm of Hugh Harbison, who farms with the help of his father Thomson, near Aghadowey, Coleraine, Co Derry. A herd of approximately 150 cows begins to calve down in early September. The farm operates a block autumn-calving system, with 75% of cows calving in the first six weeks and all cows calving within 12 weeks.

The shed has the capacity to hold approximately 100 calves at any one time and was designed in-house.

The shed is uniquely designed to suit the homemade calf feeder and while not a conventional design, it is working very well with three batches of calves having moved through the shed so far.

“The shed was built around the feeder, which is maybe something a little different. We had looked at buying a 35-calf teat feeder, but they were coming in at about £5,000 so we decided to make our own one instead,” according to Hugh. “It worked out at a fraction of the price.”

Unique design

The shed is approximately 120ft long and 38ft wide. It is made up of six spans of 20ft. An 8ft overhang is also present along the front of the shed.

The shed is laid out in eight long pens, which are each capable of holding approximately 12 to 15 calves. Smaller groups may be kept for younger calves.

Due to the layout of the shed, four of the pens are about 10ft longer than the other four pens. However, there is still ample lying space for all calves in the pens. Feeding space is the dictating factor.

The shed is designed that two pens of calves can be fed at the one time to allow for quicker feeding. The portable calf feeder is rolled into the semi-oval shape that is left between pens. Access to feed calves is provided by a door along the side of the shed.

“The design means that one man can feed over 100 calves in the shed in about 25 minutes and that about 30 calves can drink around the feeder together, which is important,” according to Hugh.

The shed is divided into eight long pens, which will hold between 10 and 15 calves, depending on the age. Feeding and bedding

Pens will be bedded with straw towards the back of the pen and left clean nearer the feeding area. Sliding doors are in place at both ends of the shed to allow for ease of access for cleaning out of pens.

The interior layout of the shed can be completely changed as calves get older to allow a silage-based diet to be fed. All penning can be lifted out to allow calves access to the front of the shed.

A large straw layback area is still left, with the front area used for feeding. Flaps run all along the front of the shed which can be opened up to allow access to the wooden feed troughs that are in place.

The floor of the shed slopes towards a small 4ft-deep slatted tank, which runs along the front of the shed. The tank is fitted with pig slats, which have smaller slits that suit young calves. This tank predominantly collects dirty water.

The door positioned along the front of the shed can also be closed to provide additional feed space.

Older calves will be moved nearer the front of the shed and given access to silage, while younger calves will be kept in the back pens and given a milk-based diet until they are old enough.

All pens are fitted with water troughs, with water piped in above the pens to allow for easy removal when smaller pens are not being used.

Meal troughs are also in place in the pens. Four hay racks are positioned in the shed, with each rack servicing two pens.

Small storage lofts are in place inside the sliding doors along the back of the shed. These are used to store straw and hay for the calves.

Cleaning out

There is a sliding door in place at either end of the shed. On one side of the shed, the door is positioned along the back of the shed, while on the other side it is along the front of the pen. This means that it is very easy to get in with a tractor to clean out all pens in the shed.

The shed is lined front and back with spaced boarding. “We had looked at the Yorkshire boarding, but I thought it was just a little bit tight and might not let enough air through, so we went with the spaced boarding,” Hugh said.

Good airflow in calf sheds is vital to dilute and remove bacteria, moisture and gases from the air around calves. The aim is to ensure a continuous movement of fresh air through the shed.

Natural ventilation is the most common form in Ireland through a combination of the stack effect and wind. The effects of the stack effect are limited in calf houses, as large amounts of heat are not produced by the calves.

It is also vital to avoid draughts on calves, which can be caused by excessive air movement. The high roof ensures that there is a large cubic capacity, which helps to reduce the disease pressure on calves, as bacteria can rise away from calf height.

“The shed has been first-class since we put it up, with three batches of calves having gone through it to date,” according to Hugh.

Cost

The total cost of the project came to approximately £30,000, which works out at a cost of £300/calf.

SHARING OPTIONS