Starting with a milking herd of 120 cows in 2000, the Healy family has now expanded to 270 cows. The aim is to surpass 300 cows in 2018. With cow numbers increasing in earnest for the past four or five years, the decision was made by the Healys in Co Wicklow to construct cubicle accommodation and a new parlour to cope with the expanding herd.

Darren and his father Eamon, who are part of the Teagasc/Glanbia monitor farm programme, farm in partnership. A greenfield site beside their existing farmyard was chosen as the base for the operations. They did not come to this conclusion lightly, with a lengthy planning stage vital, insists Darren.

Planning

Darren highlighted the planning stage as the most important aspect of the project and especially the help provided by Grasstec. “We probably viewed over 25 different parlours and set-ups in the year that it look us to plan this. We started off thinking that we needed a parlour with all the bells and whistles but we soon learned that cow flow was the most important thing to consider.” Reducing workload and optimising cow flow became the two cornerstones of the project.

Expansion

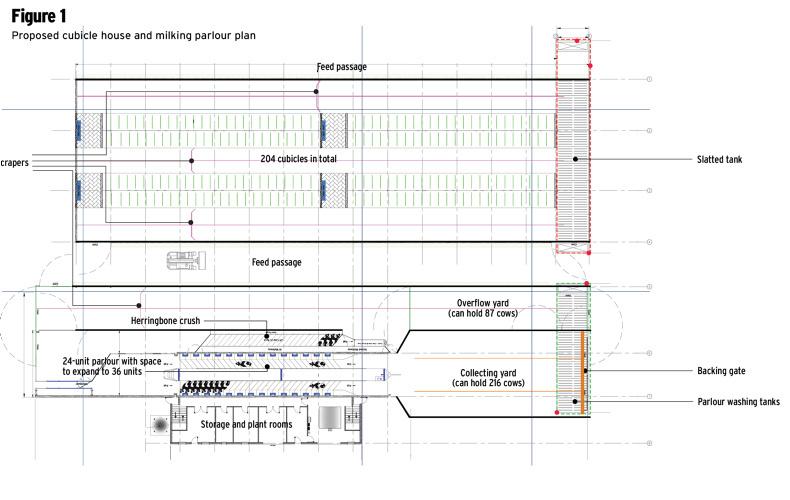

One eye was turned towards possible future expansion when the parlour and cubicles were planned out. A 24-unit parlour was installed with the pit constructed so that it can expand to 36 units in the future if required. The location of the outdoor cubicles means that they can be easily expanded in the future to cope with increasing numbers.

For now, 206 cubicles were installed and coupled with the existing housing on the farm, will be ample to cope with current numbers. With cows going to grass on 1 February, they will only be milked for approximately three weeks of the year off the cubicles, in November, negating the need for more cubicles. They will predominantly be used to hold dry cows over the winter months but it also presents the opportunity to on-off graze the herd in the spring. Something that was not an option before but could lead to increased grass utilisation.

Space

A passage is in place between the milking parlour and the cubicles, which doubles up as extra space to hold cows prior to milking. It is also used if cows need to be buffer-fed after milking. This passage, coupled with the feeding space surrounding the cubicles, allows for up to 350 cows to be buffer fed at any one time. This will help to prevent younger or weaker cows from being bullied away from feed, according to Darren.

Lie of the land

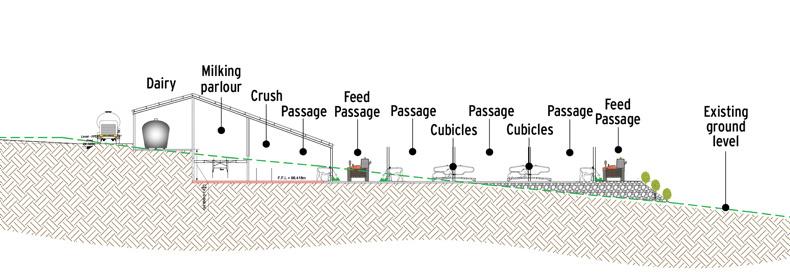

The farm is located on a slope, which meant that the project had to be designed to fit in with the lie of the land. This resulted in the dairy being approximately 12 feet higher than the parlour and cubicles.

This decision was made to best utilise the material that would be dug out, which was used to raise up the ground under the cubicles. Darren was conscious of the extra cost that would be involved if additional stone would be required to raise up a greater area under the cubicles, or if surplus material would have to be disposed of should they decide to dig further into the slope.

He was also conscious that if the dairy was down at the level of the parlour it would require the milk trucks to climb an even steeper hill to exit the yard.

The elevated dairy contains an array of rooms, each with a different purpose. A 15,000-litre capacity bulk tank is in place along with rooms used for chemical storage, general storage and an office.

Once cows exit the parlour they go through an automatic Alfco drafting system, or they can also be put through a purpose-built foot bath. Slats extend out through the drafting system in a bid to reduce the workload involved with washing down after milking. From the drafting area, cows can access the large herringbone crush which will hold up to 24 cows at one time. This is generally used for scanning cows, tail painting and tail clipping, among other jobs. It allows for large numbers of cows to be managed very quickly, according to Darren. Swan neck posts support a top bar on one side of the crush. These are not always included in these crushes but Darren viewed it as vital to ensure the safety of man and beast. As the roof of the shed was too far up it was decided that swan neck posts would be used to support the bar.

Parlour

The milking parlour is a 24-unit Fulwood machine, with the pit and shed constructed large enough that it can be easily expanded to 36 units in the future. Straight troughs were used as opposed to mangers as Darren felt that old cows can be slow to exit the parlour if mangers are in place. ACRs and a dumpline are also in place. The collecting yard is designed to hold approximately 216 cows, while a further 87 cows can be held in the overflow yard. The backing gate in the collecting yard can open up on both sides. This means that as the gate moves forward another group of cows can be put into the yard. All scrapers on the yard are Alfco automatic rope scrapers. The ropes can support up to 16t.

Braving the elements

Many farmers still have reservations about having cows out in harsh conditions but it is not something that worries Darren. “We had cattle out on kale on this farm for a long time so we are used to cattle being out. We were concerned that we may have to feed silage every day as silage would be getting wet but we haven’t had any issue with it. We are still able to feed every second day and cows are cleaning it up.” Darren also plans to plant a hedge around the cubicles to provide a wind break.

The extra dirty water that is associated with a system like this is also a concern for many farmers. However, there is a 430,000-gallon lagoon already in place on the farm which means storage is not an issue. A further 140,000-gallon tank has also been constructed between the new slatted tank at the end of the cubicles and the dirty water tank in the collecting yard. A system will be in place that slurry from these tanks can be pumped to the lagoon.

The total cost of the project once grants are paid and the VAT is claimed back will be €420,000. As the farm is run as a partnership, they were able to double up on the grant ceiling (40% of €80,000 per farmer) which were all used up on the milking equipment and the new slurry tanks. In total, they were able to claim 40% of the €160,000 ceiling, which works out at €64,000. Darren added that when farmers are costing sheds they should include a 30% contingency in case the project goes over budget.

“We included a 30% contingency when we were costing the project and we used every penny of it.” Darren also thanked his wife Kalinda and his mother Mary for all the work that has gone in to reach this point.

SHARING OPTIONS