Jeremy O’Toole is a 10th-generation farmer based in Ardoyne just outside Tullow, Co Carlow. Alongside the 250-cow dairy herd which he farms with his wife and kids, Jeremy runs an agricultural contracting business, Ardoyne Contracting.

Aside from tillage operations, all the usual services including pit silage, round baling as well as slurry and dung spreading are provided. Jeremy also harvests up to 2,500 acres of gluten-free oats under contract for Glanbia. Depending on the year, this sees the Tullow man manage anywhere up to five combines and a number of chaser bins.

Background

While most contractors today opt for a large non-telescopic wheel loader to keep grass away from self-propelled forage harvesters, Jeremy finds his needs are different. He requires a manoeuvrable loader, compact enough for farm yard duties yet well capable on the clamp.

Up until the arrival of the first pivot steer loader, the farm had a history of Massey Ferguson backhoe loaders. “Over the years we had two Massey Ferguson 50Bs, one with a backhoe and one without, before moving to a 50HX and then to a new 860 in 1995. We replaced it for another new 860 in 2001. Surprisingly, the backhoes were great on a silage pit. Flynns used to modify them for pit work, removing half of the back actor and fitting a larger oil cooler,” Jeremy said.

Following on from the backhoe days, Jeremy hired a Venieri 7.63B articulated loader for a season and also spent some time on a 9.63 model, both of which he described as good machines. However, he decided to buy a second-hand 2004 JCB TM300 in 2008.

Jeremy said: “ For a short period in 2013 we had a TM310S which we later changed for a new TM320S in 2014. The 320S was a super machine. Aside from replacing a sensor costing €300 in the latter years it worked away, clocking up 7,500 trouble-free hours. At silage, we used to have it fitted with a 12ft fork, this was the only time it came under pressure and lacked a little extra weight. That said, it was a big fork for the loader.”

Jermey's TM420S hasn’t been idle having clocked up over 1,000 hours since taking delivery 13 months ago.

Having followed the launch of the TM420, Jeremy travelled to see it at Agritechnica in 2017. “I was sold on the extra power and weight. I spoke to Kellys of Borris and priced one. At that time there was no S model but in sticking with typical JCB fashion, I expected it to come at some point. Unsure when exactly it would be I decided to buy the 420 with the intention of upgrading it for a 420S at some point.”

Jeremy took delivery of his new TM420 in autumn 2020, welcoming the significant increase in stature and power over his previous 320S.

Jeremy requires a versatile loader for use around the farm yet capable on a silage pit.

Given the time of year it spent the winter at yard duties, loading dung and feeding mainly. Keen to try it out at grass the following silage season it never actually materialised.

To his surprise, JCB announced the launch of the TM420S model sooner than he expected. Shortly after the launch, Kellys had a unit arrive which was offered to him.

Having seen and driven the loader he was well impressed by the changes brought about in the S model. So, Jeremy traded his 420 for the 420S and had his 620 wheels swapped with the 480s which came fitted on the 420S. He also had the optional auto greaser removed and refitted to the 420S.

The TM420S features the same Stage V-compliant 4.8l JCB Dieselmax engine as the TM420. However, it benefits from an additional 23hp taking it to 173hp while torque also increases from 600Nm to 690Nm.

The only downside of the large cooling pack is the loud noise the fan makes.

Jeremy pointed out that the extra power is noticeable, especially once the engine is under load. He also likes the layout of the engine from a service aspect, with all filters etc easily accessed.

It is fitted with a sizeable cooling pack which does its job in keeping the engine cool even at the most demanding of tasks, especially on the silage pit. One negative Jeremy did note was that the fan is very loud, especially while the air con is switched on.

Being a Stage V machine the engine switches off automatically after idling for a set period of time. Jeremy thinks this is a clever feature.

The engine is very accessible from a service point of view.

Married up to the engine is JCB’s in house built powershift transmission which features the 50km/h option only available to the S models. It offers eight forward and four reverse ratios, with torque lock available through all forward and reverse gears. Jeremy said that the first thing he noticed when test driving the S model was that it was much more stable on the road even at 50km/h compared to his 40km/h TM420.

The auto greaser is neatly fitted under the bonnet.

Having demo’d loaders with CVT transmissions on the pit previously, he prefers the power shift for its torque at low engine rpm. “I keep the transmission in manual mode while on the pit, usually between gears one or two and so that it’s not constantly shifting up and down gears.”

The TM420S shares the same 12-stud axles with the TM420. These are also built in-house by JCB and feature inboard oil reversed brakes front and rear. Being the 50km/h version it is equipped with dual circuit brakes instead of single and an electric parking brake.

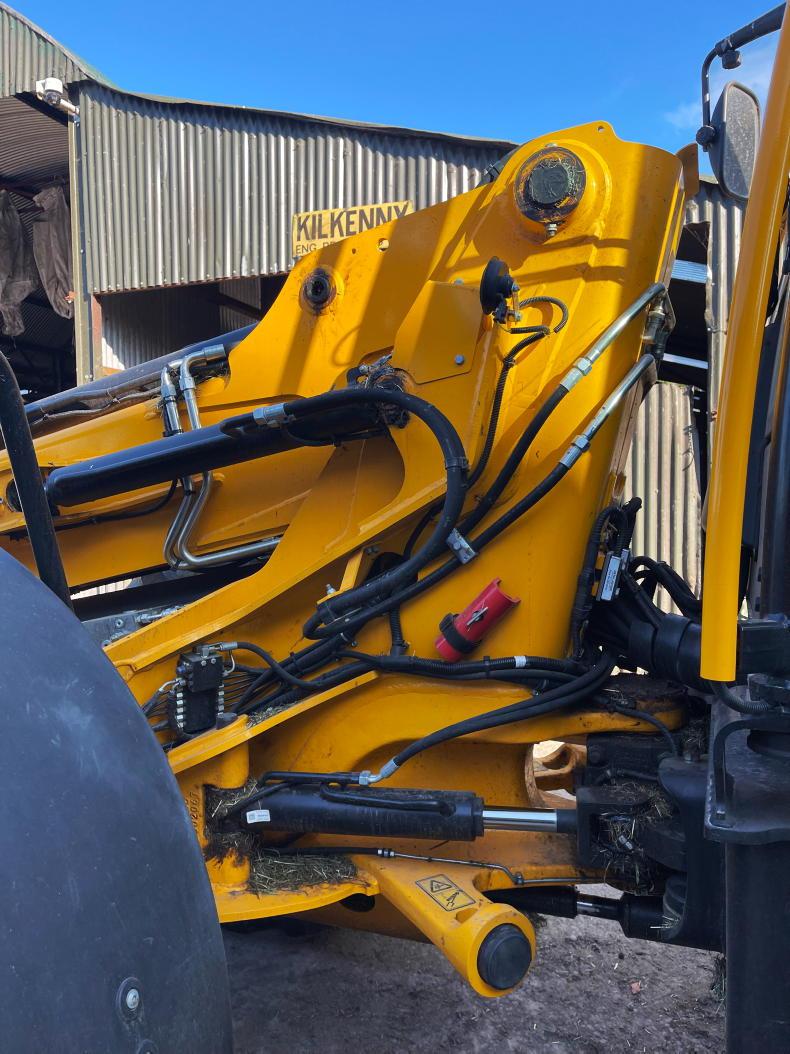

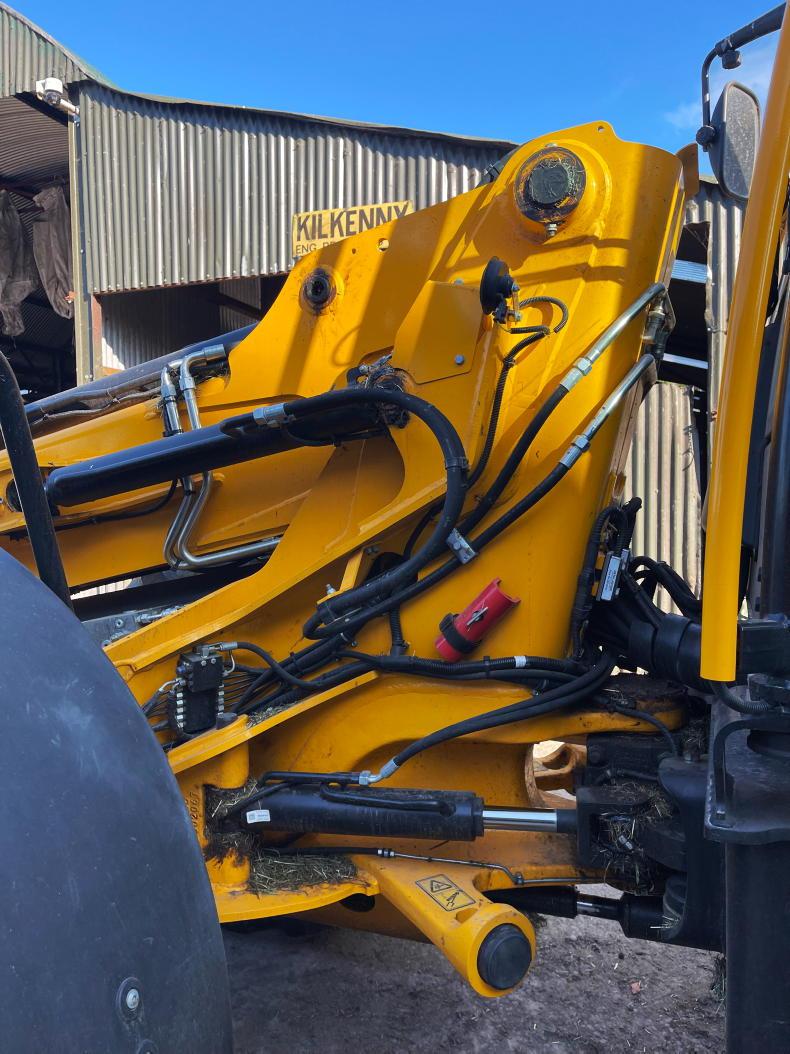

The strength in the boom and pivot was a major selling point of the TM420S.

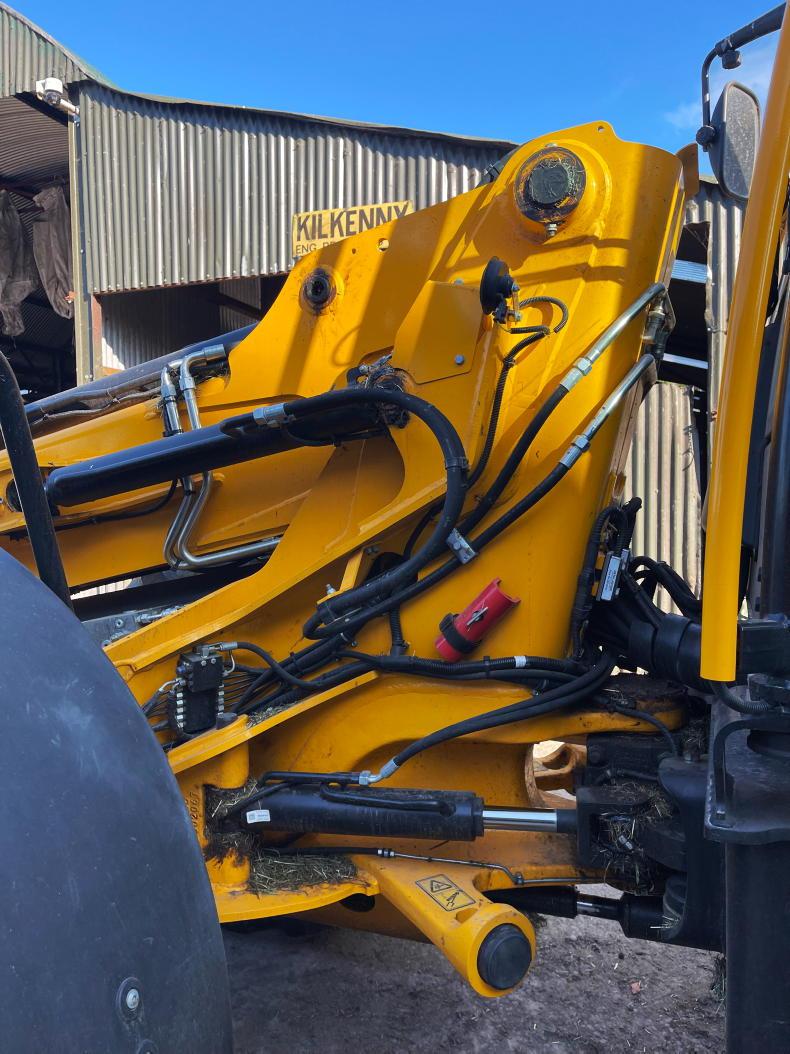

The big benefit to the TM420S compared to the TM420 according to Jeremy is the twin variable displacement piston hydraulic pump over the single pump. This boosts pump capacity from 73l/min to 100l/min. Max flow remains the same at 160l/min albeit at much lower engine rpm. This is noticeable while on the silage pit with the 12ft Redrock fork. Jeremy had the loader fitted with a Topcon A10 weighing system which he said makes easy work of loading the diet feeder accurately. Lift heights and capacities between the 420 and 420S are unchanged at 5.45m and 4.1t

Jermey's loader is fitted with the Q-fit headstock.

The TM420S benefits from JCB’s most recent Command Plus cab which the TM420 doesn’t have. Jeremy backs up JCB’s claim of increased visibility, which the firm says is increased by 13%. The joystick benefits from an assignable hot key button while the familiar rubber-membraned blister pad of switches is now positioned on the right-hand central pillar.

Jeremy feels the TM420S cab is a big improvement on the standard TM420.

Apart from a new seat, the steering column has also been tweaked according to Jeremy. He also praised the degree of refinement in terms of media and Bluetooth connectivity and the speaker system in the new cab.

Unlike his old TM320S the door is on a gas strut therefore doesn’t fold around 180 degrees.

Jeremy has fitted additional mirrors to the front mudguards which he feels are much more visible compared to the cab mirrors which can require the driver having to glance around the corner pillar depending on seating position. The doors no longer open 180° since fitted with gas struts. Jeremy doesn’t see this as a negative but more so as a positive as it leaves the cab cleaner if doors are closed.

Jermey's TM420S is fitted with the full LED worklight package.

Although the TM420 and TM420S are equipped with larger bonnets reducing rear visibility to an extent, he said that the rear view camera makes up for this. Some of the other notable optional extras include LED work lights, auto greaser, and auto reverse fan. He didn’t opt for a pickup hitch as the extra clearance around the rear ballast weight is needed on silage pits.

Jeremy had additional wing mirrors fitted which he finds are better than the cab mounted.

Build quality is a major standout for Jeremy, especially in around the centre pivot. “It really is a big brother to the TM320S which from my experience had little faults. It weighs in just over 1,600kg heavier which as can be seen has gone into things like making the centre pivot, boom and headstock stronger.”

Switches have been relocated to the right hand pillar in typical JCB fashion.

Jeremy said: “With just over 1,000 hours clocked up in 12 months, the loader has performed well. Aside from more horsepower, the S version brings more to the TM420 than it did to the TM320. I always felt a bigger version of the TM320S would be the ideal machine for our setup – especially on the pit for pushing power moving grass away from the Jaguar 840 as well as stability. We need a telescopic loader for its lift height on the farm which ruled out the move to a JCB 413 or similar and anything bigger is too costly and not suited to tight yard work. The added benefit of a pivot steer is that it leaves tight areas easily worked, especially around the yard feeding.

Control layout is one of Jeremy's likes.

“Comfort and the control layout in the cab is definitely among the best on the market. I couldn’t fault build quality with the 320S which is even more so the case with the 420S. On the pit, I’d happily put it up against a 419S. Kitted out with the 620 tyres and front duals it’s a very stable and well able to roll any pit. It’s the ideal size for us, it’s not too large for farm work but yet not too small for pit work.”

Jeremy and his son Fergal O'Toole .

Engine: Stage V 4.8l JCB Dieselmax.

Horsepower: 173hp.

Transmission: 50km/h eight-speed powershift with torque lock.

Unladen weight: 9,779kg.

Tipping load: 4,100kg.

Tyres: 620/70 R26.

Fuel and AdBlue tank capacity: 160l and 29l.

Price: €155,000 plus VAT.

Jeremy O’Toole is a 10th-generation farmer based in Ardoyne just outside Tullow, Co Carlow. Alongside the 250-cow dairy herd which he farms with his wife and kids, Jeremy runs an agricultural contracting business, Ardoyne Contracting.

Aside from tillage operations, all the usual services including pit silage, round baling as well as slurry and dung spreading are provided. Jeremy also harvests up to 2,500 acres of gluten-free oats under contract for Glanbia. Depending on the year, this sees the Tullow man manage anywhere up to five combines and a number of chaser bins.

Background

While most contractors today opt for a large non-telescopic wheel loader to keep grass away from self-propelled forage harvesters, Jeremy finds his needs are different. He requires a manoeuvrable loader, compact enough for farm yard duties yet well capable on the clamp.

Up until the arrival of the first pivot steer loader, the farm had a history of Massey Ferguson backhoe loaders. “Over the years we had two Massey Ferguson 50Bs, one with a backhoe and one without, before moving to a 50HX and then to a new 860 in 1995. We replaced it for another new 860 in 2001. Surprisingly, the backhoes were great on a silage pit. Flynns used to modify them for pit work, removing half of the back actor and fitting a larger oil cooler,” Jeremy said.

Following on from the backhoe days, Jeremy hired a Venieri 7.63B articulated loader for a season and also spent some time on a 9.63 model, both of which he described as good machines. However, he decided to buy a second-hand 2004 JCB TM300 in 2008.

Jeremy said: “ For a short period in 2013 we had a TM310S which we later changed for a new TM320S in 2014. The 320S was a super machine. Aside from replacing a sensor costing €300 in the latter years it worked away, clocking up 7,500 trouble-free hours. At silage, we used to have it fitted with a 12ft fork, this was the only time it came under pressure and lacked a little extra weight. That said, it was a big fork for the loader.”

Jermey's TM420S hasn’t been idle having clocked up over 1,000 hours since taking delivery 13 months ago.

Having followed the launch of the TM420, Jeremy travelled to see it at Agritechnica in 2017. “I was sold on the extra power and weight. I spoke to Kellys of Borris and priced one. At that time there was no S model but in sticking with typical JCB fashion, I expected it to come at some point. Unsure when exactly it would be I decided to buy the 420 with the intention of upgrading it for a 420S at some point.”

Jeremy took delivery of his new TM420 in autumn 2020, welcoming the significant increase in stature and power over his previous 320S.

Jeremy requires a versatile loader for use around the farm yet capable on a silage pit.

Given the time of year it spent the winter at yard duties, loading dung and feeding mainly. Keen to try it out at grass the following silage season it never actually materialised.

To his surprise, JCB announced the launch of the TM420S model sooner than he expected. Shortly after the launch, Kellys had a unit arrive which was offered to him.

Having seen and driven the loader he was well impressed by the changes brought about in the S model. So, Jeremy traded his 420 for the 420S and had his 620 wheels swapped with the 480s which came fitted on the 420S. He also had the optional auto greaser removed and refitted to the 420S.

The TM420S features the same Stage V-compliant 4.8l JCB Dieselmax engine as the TM420. However, it benefits from an additional 23hp taking it to 173hp while torque also increases from 600Nm to 690Nm.

The only downside of the large cooling pack is the loud noise the fan makes.

Jeremy pointed out that the extra power is noticeable, especially once the engine is under load. He also likes the layout of the engine from a service aspect, with all filters etc easily accessed.

It is fitted with a sizeable cooling pack which does its job in keeping the engine cool even at the most demanding of tasks, especially on the silage pit. One negative Jeremy did note was that the fan is very loud, especially while the air con is switched on.

Being a Stage V machine the engine switches off automatically after idling for a set period of time. Jeremy thinks this is a clever feature.

The engine is very accessible from a service point of view.

Married up to the engine is JCB’s in house built powershift transmission which features the 50km/h option only available to the S models. It offers eight forward and four reverse ratios, with torque lock available through all forward and reverse gears. Jeremy said that the first thing he noticed when test driving the S model was that it was much more stable on the road even at 50km/h compared to his 40km/h TM420.

The auto greaser is neatly fitted under the bonnet.

Having demo’d loaders with CVT transmissions on the pit previously, he prefers the power shift for its torque at low engine rpm. “I keep the transmission in manual mode while on the pit, usually between gears one or two and so that it’s not constantly shifting up and down gears.”

The TM420S shares the same 12-stud axles with the TM420. These are also built in-house by JCB and feature inboard oil reversed brakes front and rear. Being the 50km/h version it is equipped with dual circuit brakes instead of single and an electric parking brake.

The strength in the boom and pivot was a major selling point of the TM420S.

The big benefit to the TM420S compared to the TM420 according to Jeremy is the twin variable displacement piston hydraulic pump over the single pump. This boosts pump capacity from 73l/min to 100l/min. Max flow remains the same at 160l/min albeit at much lower engine rpm. This is noticeable while on the silage pit with the 12ft Redrock fork. Jeremy had the loader fitted with a Topcon A10 weighing system which he said makes easy work of loading the diet feeder accurately. Lift heights and capacities between the 420 and 420S are unchanged at 5.45m and 4.1t

Jermey's loader is fitted with the Q-fit headstock.

The TM420S benefits from JCB’s most recent Command Plus cab which the TM420 doesn’t have. Jeremy backs up JCB’s claim of increased visibility, which the firm says is increased by 13%. The joystick benefits from an assignable hot key button while the familiar rubber-membraned blister pad of switches is now positioned on the right-hand central pillar.

Jeremy feels the TM420S cab is a big improvement on the standard TM420.

Apart from a new seat, the steering column has also been tweaked according to Jeremy. He also praised the degree of refinement in terms of media and Bluetooth connectivity and the speaker system in the new cab.

Unlike his old TM320S the door is on a gas strut therefore doesn’t fold around 180 degrees.

Jeremy has fitted additional mirrors to the front mudguards which he feels are much more visible compared to the cab mirrors which can require the driver having to glance around the corner pillar depending on seating position. The doors no longer open 180° since fitted with gas struts. Jeremy doesn’t see this as a negative but more so as a positive as it leaves the cab cleaner if doors are closed.

Jermey's TM420S is fitted with the full LED worklight package.

Although the TM420 and TM420S are equipped with larger bonnets reducing rear visibility to an extent, he said that the rear view camera makes up for this. Some of the other notable optional extras include LED work lights, auto greaser, and auto reverse fan. He didn’t opt for a pickup hitch as the extra clearance around the rear ballast weight is needed on silage pits.

Jeremy had additional wing mirrors fitted which he finds are better than the cab mounted.

Build quality is a major standout for Jeremy, especially in around the centre pivot. “It really is a big brother to the TM320S which from my experience had little faults. It weighs in just over 1,600kg heavier which as can be seen has gone into things like making the centre pivot, boom and headstock stronger.”

Switches have been relocated to the right hand pillar in typical JCB fashion.

Jeremy said: “With just over 1,000 hours clocked up in 12 months, the loader has performed well. Aside from more horsepower, the S version brings more to the TM420 than it did to the TM320. I always felt a bigger version of the TM320S would be the ideal machine for our setup – especially on the pit for pushing power moving grass away from the Jaguar 840 as well as stability. We need a telescopic loader for its lift height on the farm which ruled out the move to a JCB 413 or similar and anything bigger is too costly and not suited to tight yard work. The added benefit of a pivot steer is that it leaves tight areas easily worked, especially around the yard feeding.

Control layout is one of Jeremy's likes.

“Comfort and the control layout in the cab is definitely among the best on the market. I couldn’t fault build quality with the 320S which is even more so the case with the 420S. On the pit, I’d happily put it up against a 419S. Kitted out with the 620 tyres and front duals it’s a very stable and well able to roll any pit. It’s the ideal size for us, it’s not too large for farm work but yet not too small for pit work.”

Jeremy and his son Fergal O'Toole .

Engine: Stage V 4.8l JCB Dieselmax.

Horsepower: 173hp.

Transmission: 50km/h eight-speed powershift with torque lock.

Unladen weight: 9,779kg.

Tipping load: 4,100kg.

Tyres: 620/70 R26.

Fuel and AdBlue tank capacity: 160l and 29l.

Price: €155,000 plus VAT.

SHARING OPTIONS