German fertiliser spreader manufacturer Rauch recently held a press event near its headquarters located in southwest Germany, near the town of Rheinmünster, along the French border.

Rauch has remained a family-owned company since it was first founded in 1880 by Franz Rauch. Now in its fifth generation, the business remains entirely focused on fertiliser spreading technology.

The company employs in the region of 400 staff on its single site in Rheinmünster. Last year, turnover amounted to €15 million, of which 8% is consistently reinvested back into R&D.

The product portfolio is broken down into three main segments: spinner-type fertiliser spreaders, pneumatic fertiliser spreaders and pneumatic air seeders which are distributed by its close partner, Kuhn.

Currently, the Rauch has an official presence in 43 countries, with exports accounting for 70% of the factory’s output. While the Rauch brand has an official presence here in Ireland through its distribution partner, Cork Farm Machinery, in other markets its machines are sold under the Kuhn brand, a brand with which Rauch has close synergies.

At the event, Rauch showcased its new Axis 25 spreader alongside a number of new technologies, some of which remain under wraps until later in the year.

Axis 25: a new mid-sized offering

The Axis 25 is a new spreader offering developed to slot between the Axis 20.2 and Axis 30.2 models. The spreader has a maximum payload of 2,400kg, and is aimed towards medium-sized farmers and contractors. While building on the success of the current Axis range, the Axis 25 incorporates several new features. These include a new hopper design, new spreading discs, improved border spreading and software improvements.

The Telimat X border control system has been further refined for better precision.

With the increased use of organic fertilisers such as pellets with a lower density, Rauch has taken this into account with the Axis 25 and offers flowrates up to 675kg/min due to a revised hopper openings and discharge system. The Axis 25 is also better geared up digitally, with 18 part-width section control and functions such as automatic application map management and precise low level sensors. In terms of control, the spreader can be used with a CCI 60 terminal or any other Isobus terminal.

Updated border spreading

The Telimat X border spreading system has been refined for greater precision. Two additional deflector vanes (all of which are individually replaceable) have been added and an extended spreading angle result in more sharply defined boundaries.

Instead of six disc options, two disc options cover all spreading widths and applications from 12m to 42m.

Disc placement has also been tweaked to prevent the spreader disc on the opposite side from throwing fertiliser over. Another feature sure to be welcomed is the practical move away from six-disc types to just two for the entire spreading range from 12m to 42m. One set of discs takes care of spreading between 12m and 28m while the second set caters for 24m to 42m spreading.

SpeedServo and modular gearbox

The Axis 25 features a new SpeedServo, which offers a 20 % larger drop point range and up to 25 % faster adjustment, meaning that the spreader can adapt more quickly to changes in forward speed. The modular drive gearbox now has separately replaceable sensors, making maintenance and adjustment easier.

In terms of aesthetics, the Axis 25 is a more eye-catching machine in comparison to the rest of its stablemates. Not only does the hopper look more modern, but it is said to empty better and has less area for granules to build up around the chassis, according to Rauch. The cover can now be locked in washing position whereby it remains open marginally to allow the hopper to dry after being washed.

A new ladder provides better access to the hopper.

Other new features improving convenience include a redesigned folding access ladder, and foot engaged rubber coated castor wheels for storage. This leaves engagement of the storage wheels easier accessed from the side of the hopper while tilting the spreader back slightly for easier attachment to the tractor.

Further refinements for OptiPoint Pro+ headland management

At the field event, Rauch presented a more refined version of its OptiPoint Pro headland management system.

While traditional headland management systems relied entirely in simple speed and width data, OptiPoint Pro+ analyses a wide range of parameters in real time, including machine characteristics, field geometry and specific fertiliser properties. Based on this data, the system can calculate the optimum switch-on point when entering the headland, correct adjustment of the fertiliser quantity and spreading performance on the headland and the exact switch-off point when exiting the headland. According to Rauch, the system takes into account the flight distance of the fertiliser and the spreading width of the machine. All actions are documented on the Isobus terminal for full traceability.

The OptiPoint Pro+ headland management system now analyses a wide range of parameters in real time for better precision.

A newly defined switch-off point, means the driver does not have to drive into the fertilised areas unnecessarily. According to Rauch, the system automatically adapts to different fertiliser types and working conditions.

OptiPoint Pro+ will be available as a software upgrade for many Rauch spreaders this coming autumn.

FieldEngine – Farm management platform collaboration

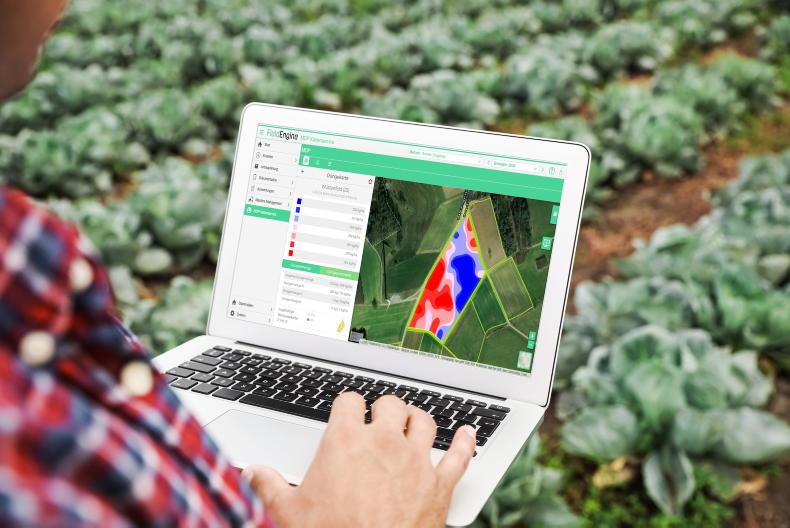

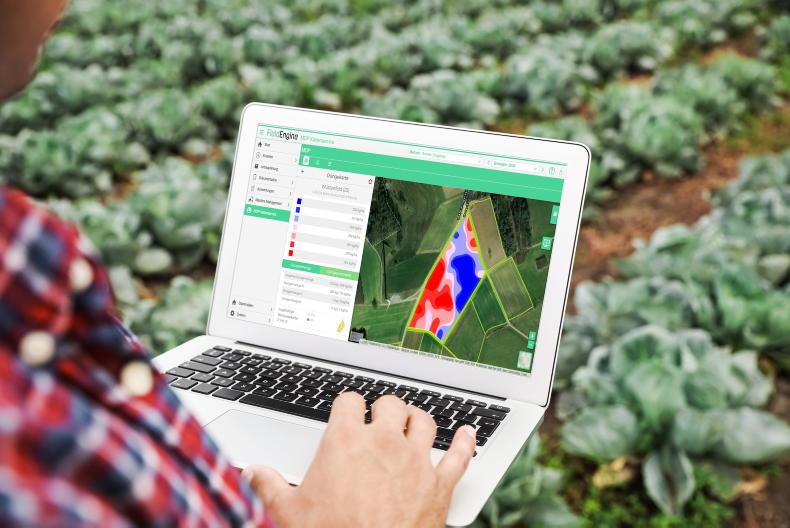

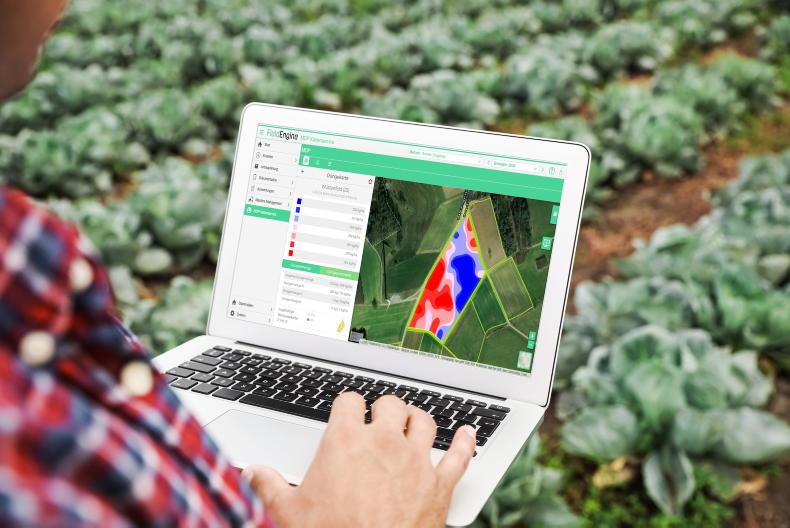

Rauch announced that it is working in collaboration with other key industry players to develop a new farm management system called FieldEngine which will be publicly unveiled at Agritechnica this November.

Together with manufacturers Krone, Zunhammer and Nexat, the new cross-manufacturer software platform aims to be a clear contrast to the solutions already existing from individual companies.

FieldEngine is based on a proven system that has been significantly enhanced by the consortium, better addressing all processes of farm management including land and machine management to the creation of application maps and documentation.

Ensuring a wide range of machine compatibility and not specific to a single brand, the open platform supports established standards such as ISOXML and the agrirouter platform. Rauch believe FieldEngine will be an ideal solution for those running mixed branded fleets.

Rauch is working with other industry players such as Krone, Zunhammer and Nexat to develop the FieldEngine open farm management platform.

Although market ready, the platform is currently being rolled out on a number of German-speaking pilot farms.

Isobus control for smaller MDS spreaders

Rauch has also added Isobus control functionality to its MDS range of single hopper spreaders.

The Rauch MDS Isobus system can be operated either directly via the tractor’s Isobus terminal or via an external CCI 800 or 1200 terminal. This allows farmers and contractors to easily integrate MDS machines into existing fleets, regardless of the tractor manufacturer. The user interface is said to be intuitively designed.

The MDS is available in Q and W versions. The former uses a speed-dependant rate control system in order to determine the flowrate of the fertiliser in question. A calibration test is required via Isobus terminal to determine the flow factor. Meanwhile, the MDS W Isobus version goes one step further.

Here, a weighing frame takes over the automatic and continuous control of the application rate. This eliminates the need for calibration tests, saves time and minimises potential error.

These terminals also offer activations for section control, GPS guidance and the task controller for job documentation.

The MDS Isobus can also be used on tractors without a factory-fitted Isobus wiring harness.

The system can be easily connected via a simple three-pin 12V power supply and a seven-pin signal socket for the driving speed signal.

There is also an Isobus Lite package available. In combination with the compact CCI 60 terminal, this Isobus Lite package gives smaller or older tractors access to the digital application world albeit with reduced functionality without task controller, section control or GPS connection.

There is also an Isobus Lite package, offering reduced functionality without task controller, section control or GPS connection. It uses the new CCI 60 terminal.

German fertiliser spreader manufacturer Rauch recently held a press event near its headquarters located in southwest Germany, near the town of Rheinmünster, along the French border.

Rauch has remained a family-owned company since it was first founded in 1880 by Franz Rauch. Now in its fifth generation, the business remains entirely focused on fertiliser spreading technology.

The company employs in the region of 400 staff on its single site in Rheinmünster. Last year, turnover amounted to €15 million, of which 8% is consistently reinvested back into R&D.

The product portfolio is broken down into three main segments: spinner-type fertiliser spreaders, pneumatic fertiliser spreaders and pneumatic air seeders which are distributed by its close partner, Kuhn.

Currently, the Rauch has an official presence in 43 countries, with exports accounting for 70% of the factory’s output. While the Rauch brand has an official presence here in Ireland through its distribution partner, Cork Farm Machinery, in other markets its machines are sold under the Kuhn brand, a brand with which Rauch has close synergies.

At the event, Rauch showcased its new Axis 25 spreader alongside a number of new technologies, some of which remain under wraps until later in the year.

Axis 25: a new mid-sized offering

The Axis 25 is a new spreader offering developed to slot between the Axis 20.2 and Axis 30.2 models. The spreader has a maximum payload of 2,400kg, and is aimed towards medium-sized farmers and contractors. While building on the success of the current Axis range, the Axis 25 incorporates several new features. These include a new hopper design, new spreading discs, improved border spreading and software improvements.

The Telimat X border control system has been further refined for better precision.

With the increased use of organic fertilisers such as pellets with a lower density, Rauch has taken this into account with the Axis 25 and offers flowrates up to 675kg/min due to a revised hopper openings and discharge system. The Axis 25 is also better geared up digitally, with 18 part-width section control and functions such as automatic application map management and precise low level sensors. In terms of control, the spreader can be used with a CCI 60 terminal or any other Isobus terminal.

Updated border spreading

The Telimat X border spreading system has been refined for greater precision. Two additional deflector vanes (all of which are individually replaceable) have been added and an extended spreading angle result in more sharply defined boundaries.

Instead of six disc options, two disc options cover all spreading widths and applications from 12m to 42m.

Disc placement has also been tweaked to prevent the spreader disc on the opposite side from throwing fertiliser over. Another feature sure to be welcomed is the practical move away from six-disc types to just two for the entire spreading range from 12m to 42m. One set of discs takes care of spreading between 12m and 28m while the second set caters for 24m to 42m spreading.

SpeedServo and modular gearbox

The Axis 25 features a new SpeedServo, which offers a 20 % larger drop point range and up to 25 % faster adjustment, meaning that the spreader can adapt more quickly to changes in forward speed. The modular drive gearbox now has separately replaceable sensors, making maintenance and adjustment easier.

In terms of aesthetics, the Axis 25 is a more eye-catching machine in comparison to the rest of its stablemates. Not only does the hopper look more modern, but it is said to empty better and has less area for granules to build up around the chassis, according to Rauch. The cover can now be locked in washing position whereby it remains open marginally to allow the hopper to dry after being washed.

A new ladder provides better access to the hopper.

Other new features improving convenience include a redesigned folding access ladder, and foot engaged rubber coated castor wheels for storage. This leaves engagement of the storage wheels easier accessed from the side of the hopper while tilting the spreader back slightly for easier attachment to the tractor.

Further refinements for OptiPoint Pro+ headland management

At the field event, Rauch presented a more refined version of its OptiPoint Pro headland management system.

While traditional headland management systems relied entirely in simple speed and width data, OptiPoint Pro+ analyses a wide range of parameters in real time, including machine characteristics, field geometry and specific fertiliser properties. Based on this data, the system can calculate the optimum switch-on point when entering the headland, correct adjustment of the fertiliser quantity and spreading performance on the headland and the exact switch-off point when exiting the headland. According to Rauch, the system takes into account the flight distance of the fertiliser and the spreading width of the machine. All actions are documented on the Isobus terminal for full traceability.

The OptiPoint Pro+ headland management system now analyses a wide range of parameters in real time for better precision.

A newly defined switch-off point, means the driver does not have to drive into the fertilised areas unnecessarily. According to Rauch, the system automatically adapts to different fertiliser types and working conditions.

OptiPoint Pro+ will be available as a software upgrade for many Rauch spreaders this coming autumn.

FieldEngine – Farm management platform collaboration

Rauch announced that it is working in collaboration with other key industry players to develop a new farm management system called FieldEngine which will be publicly unveiled at Agritechnica this November.

Together with manufacturers Krone, Zunhammer and Nexat, the new cross-manufacturer software platform aims to be a clear contrast to the solutions already existing from individual companies.

FieldEngine is based on a proven system that has been significantly enhanced by the consortium, better addressing all processes of farm management including land and machine management to the creation of application maps and documentation.

Ensuring a wide range of machine compatibility and not specific to a single brand, the open platform supports established standards such as ISOXML and the agrirouter platform. Rauch believe FieldEngine will be an ideal solution for those running mixed branded fleets.

Rauch is working with other industry players such as Krone, Zunhammer and Nexat to develop the FieldEngine open farm management platform.

Although market ready, the platform is currently being rolled out on a number of German-speaking pilot farms.

Isobus control for smaller MDS spreaders

Rauch has also added Isobus control functionality to its MDS range of single hopper spreaders.

The Rauch MDS Isobus system can be operated either directly via the tractor’s Isobus terminal or via an external CCI 800 or 1200 terminal. This allows farmers and contractors to easily integrate MDS machines into existing fleets, regardless of the tractor manufacturer. The user interface is said to be intuitively designed.

The MDS is available in Q and W versions. The former uses a speed-dependant rate control system in order to determine the flowrate of the fertiliser in question. A calibration test is required via Isobus terminal to determine the flow factor. Meanwhile, the MDS W Isobus version goes one step further.

Here, a weighing frame takes over the automatic and continuous control of the application rate. This eliminates the need for calibration tests, saves time and minimises potential error.

These terminals also offer activations for section control, GPS guidance and the task controller for job documentation.

The MDS Isobus can also be used on tractors without a factory-fitted Isobus wiring harness.

The system can be easily connected via a simple three-pin 12V power supply and a seven-pin signal socket for the driving speed signal.

There is also an Isobus Lite package available. In combination with the compact CCI 60 terminal, this Isobus Lite package gives smaller or older tractors access to the digital application world albeit with reduced functionality without task controller, section control or GPS connection.

There is also an Isobus Lite package, offering reduced functionality without task controller, section control or GPS connection. It uses the new CCI 60 terminal.

SHARING OPTIONS