Based in the townland of Taughmaconnell, Co Roscommon, Kelvin Kelly and his father Enda run a 100-cow dairy enterprise alongside a sizable beef-finishing unit and small agri contracting business.

Four years ago Kelvin returned home full-time from college and the decision was made to consolidate the agri contracting business to focus entirely on round baling and venture into dairying.

However, the lads still undertake all machinery-related tasks in-house, with the exception of umbilical slurry spreading. Keen to hit the ground running when venturing into milk, Kelvin knew that growing as much quality grass as possible would be key. Knowing fertiliser was going to be one of the higher input costs, he decided to upgrade the older Amazone ZA-M twin disc machine on the farm.

TAMS grant aid

Being a young qualified farmer, Kelvin applied and was later approved for 60% grant aid through the TAMS Young Farmers Capital Investment Scheme (YFCIS) to purchase a new fertiliser spreader with GPS section control and weight cells. After considering all the possible avenues, Kelvin and Enda were drawn back to Amazone for a number of reasons, helped by the reliability of their previous machine and dealer backup. The spreader bought was an Amazone ZA-V 2000 Profis Tronic model.

In order to qualify for TAMS funding, the spreader must be equipped with weigh cells and automatic GPS section control. Therefore, the ZA-V Profis Tronic was the go-to model within the Amazone portfolio, offering enough but not too much technology, Kelvin felt.

In layman’s terms, 2000 relates to the 2,000l hopper capacity, Profis refers to the onboard weighing system and Tronic refers to the mechanical PTO drive.

“With no prior experience to GPS section control and weigh cells, we were keen to stick with local dealer, Paraic Dwyer, knowing what the backup service was like, having bought other machines off them over the years,” Kelvin explained.

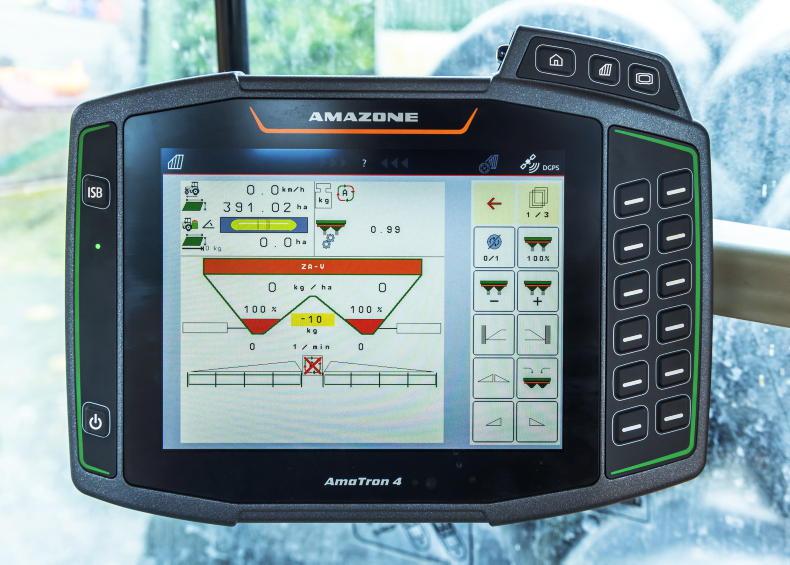

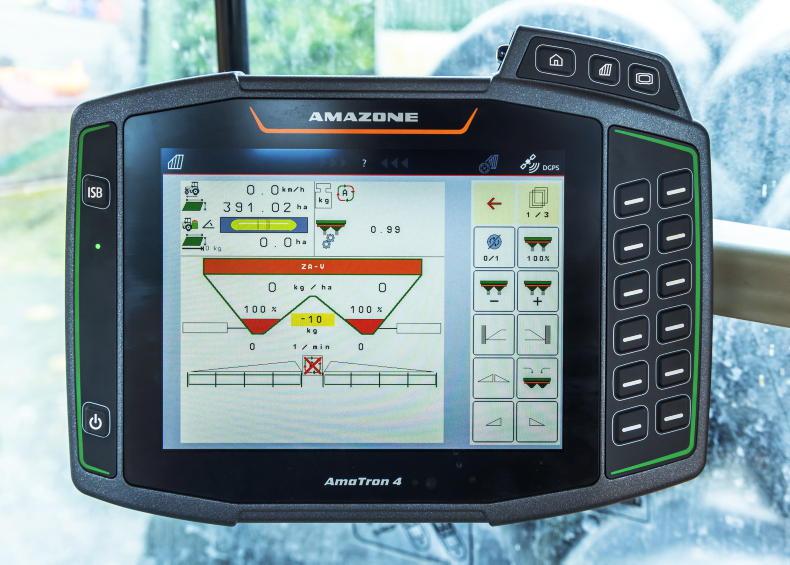

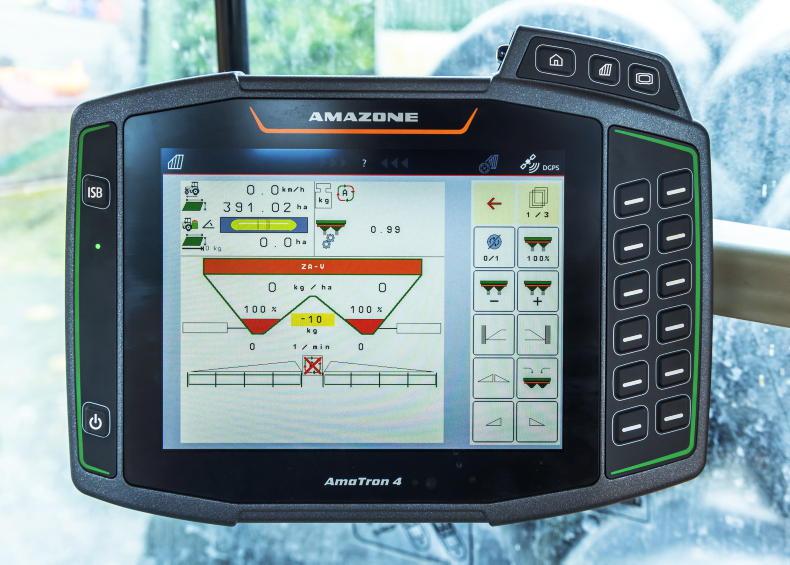

Having had no GPS system on any tractor at the time, Kelvin sought grant aid for a GPS control unit too. To keep things straightforward, he opted to go with Amazone’s own Amatron 4 Isobus terminal which offered the flexibility of being an independent GPS or Isobus terminal, meaning it could be used for guidance or tasks, or to control other machines.

Setup

Kelvin’s spreader features a good level of specification, much of which Amazone offer as standard on its grant eligible machines. These options include a manual roll-over hopper cover (hydraulic optional), castor storage wheels, access ladder and a headland management kit.

“Although fertiliser prices are back from the highs they were at when we bought the spreader, they’re still a huge farm cost. So with this in mind, and the ongoing limitations the quantity and product types that can be spread, accuracy is critical,” he pointed out.

“For a machine that can spread with such accuracy, setup was much easier than what we initially expected. Once the blend is selected on the mySpreader app, along with the intended application rate and spread width, physically it’s just a matter of adjusting vane position. Once the desired application rate has been inputted into the terminal, the spreader automatically establishes the flowrate and constantly makes shutter adjustments relative to the tractors forward speed in order to maintain the set rate.

To date, the spreader has spread in the region of 300t trouble free.

“In hindsight, I’d have probably gone for the next hopper size up, the 2,000l will still hold four bulk bags no issue, but that extra bit of space would be welcome.

“We might look into the option of an extension at some point. When it comes to hooking it on and off, the castor wheels are a super job and the way it is designed leaves for good room between the tractor wheel and hopper to connect the PTO and hoses.”

Section control and border spreading

“Section control is a feature we wouldn’t be without now. It really takes the work out of spreading fertiliser. You couldn’t credit how accurate it is. Aside from eliminating overlap, we’ve doubled our spreading width from 12m to 24m, all the while increasing accuracy, regardless if it’s day or night,” Kelvin said.

Amazone achieves up to eight part-width section control by altering the fertiliser drop point and adjusting shutter position, while maintaining the speed of both outward turning discs.

With no guidance previously, Kelvin opted for the higher-end AmaTron 4 Isobus terminal with GPS manual guidance which was used up until the arrival of a new John Deere 6R130 early last year. Being a full spec machine with Deere’s own Greenstar guidance and Autotrac autosteer along with Isobus, he has since chosen to plug the spreaders Isobus cable directly into the tractors socket and operate the spreader via John Deere’s guidance and Isobus terminal.

“The Amatron 4 terminal is a user-friendly system and does work very well. However, now that the new tractor has its own Isobus terminal and guidance, it leaves hooking on and off the spreader much quicker and removes the need for an extra terminal in the cab. That’s really the only reason we’ve since stuck with Isobus,” Kelvin said.

The spreader is equipped with the electrically adjustable Limiter V+ border spreading kit. From the terminal, border and watercourse spreading modes can be selected with the touch of a button. These presets change the degree in which the deflector kit is lowered.

Calibration and build quality

As part of the offer at the time, the spreader came with Amazone’s EasyCheck calibration mats. Essentially, the mats are a digital version of traditional trays used for tray test calibrations. Once the mats have been laid out and the spreader has passed over them, each mat is photographed through the mySpreader app, where the results are analysed. The operator is then notified of any necessary setting changes.

Kelvin finds the mats a great job and a much faster way of calibrating the spreader in comparison to trays. They’re much easier stored which is a bonus too, he said.

“With the exception of some Nitro Fert products, pretty much all the fertilisers we have used so far are on the Amazone database, which leaves setup quick and easy when going between products.”

Amazone (like most manufacturers) offers a service whereby customers can send samples of a particular blend or product direct to its factory for analysis, where it will then be available on the app.

Being a Profis spreader means it is equipped with a twin-cell weighing system which was also a key selling point for Kelvin: “With all our paddocks mapped on Pasture Base, I know quickly how many kilograms are needed for a particular paddock before leaving the yard and know that when I return empty, the paddock has got what was required, no more, no less.”

Now entering its fourth working season rust free, Kelvin is very impressed with both build and paint quality. That said, he is meticulous with how the spreader is maintained. After use, it is washed thoroughly and stored indoors. Before winter storage it is also sprayed with oil and stored uncover.

Savings

Now spreading with full GPS autosteer and section control, the Kellys are confident in knowing that each paddock is evenly and accurately spread, noting a big improvement in how even their grass covers are.

“It’s a combination of a more accurate spread pattern, the section control, weigh cells and the headland kit. On a paddock-by-paddock basis there are fertiliser savings. However, it’s a hard one to quantify by just how much having not had weigh cells previously and taking into account that overlaps don’t necessarily always translate to a complete loss of product, it’s more inefficient use of product.

“I suppose you could say that if there’s less overlap, soil fertility is bound to be more consistent too. Even if there was only one tonne of protected urea being saved per year by reducing overlaps, etc. At a cost of €550/tonne, then there’s an noticeable saving.”

Verdict

About to enter their fourth season with the spreader, the Kellys are delighted with how it has performed and the results.

“We spread in the region of 100t annually, that’s including what we spread for an uncle. So after 300t, the spreader hasn’t missed a beat.

“Between how easy it is set up and used, along with the section control and headland kit, the work has been taken out of spreading fertiliser and has left it a job that can be done any time of the day or night, with a guarantee of accurate results.

“Honestly, it’s a machine we probably wouldn’t have invested in without grant aid, purely down to cost. But now used to what it is capable of, I don’t think it’s a machine that we would be without,” Kelvin added.

Likes

Ease of use.Storage wheels.Accuracy. Dislikes

Along with an extra step on the access ladder, one on both sides would be a benefit.Spec

Model: ZA-V 2600 Profis Tronic. Spread width: 10 to 36m. Hopper capacity: 2,000l. Empty weight: 366kg. Drive type: PTO.Section control method: drop point and shutter adjustment. List price: €24,000 plus VAT. (Isobus ready).

Since the arrival of a new full spec John Deere 6R130, Kelvin operates the spreader via Isobus.

Kelvin would have liked to have an access ladder on both sides of the hopper.

Amazone achives its eight-part width section control by altering fertiliser flow rate and drop point.

The 2,000l hopper will hold four bulk bags comfortably.

Kelvin initially used the Amatron 4 terminal for the control of the spreader, as well as GPS guidance and section control.

Based in the townland of Taughmaconnell, Co Roscommon, Kelvin Kelly and his father Enda run a 100-cow dairy enterprise alongside a sizable beef-finishing unit and small agri contracting business.

Four years ago Kelvin returned home full-time from college and the decision was made to consolidate the agri contracting business to focus entirely on round baling and venture into dairying.

However, the lads still undertake all machinery-related tasks in-house, with the exception of umbilical slurry spreading. Keen to hit the ground running when venturing into milk, Kelvin knew that growing as much quality grass as possible would be key. Knowing fertiliser was going to be one of the higher input costs, he decided to upgrade the older Amazone ZA-M twin disc machine on the farm.

TAMS grant aid

Being a young qualified farmer, Kelvin applied and was later approved for 60% grant aid through the TAMS Young Farmers Capital Investment Scheme (YFCIS) to purchase a new fertiliser spreader with GPS section control and weight cells. After considering all the possible avenues, Kelvin and Enda were drawn back to Amazone for a number of reasons, helped by the reliability of their previous machine and dealer backup. The spreader bought was an Amazone ZA-V 2000 Profis Tronic model.

In order to qualify for TAMS funding, the spreader must be equipped with weigh cells and automatic GPS section control. Therefore, the ZA-V Profis Tronic was the go-to model within the Amazone portfolio, offering enough but not too much technology, Kelvin felt.

In layman’s terms, 2000 relates to the 2,000l hopper capacity, Profis refers to the onboard weighing system and Tronic refers to the mechanical PTO drive.

“With no prior experience to GPS section control and weigh cells, we were keen to stick with local dealer, Paraic Dwyer, knowing what the backup service was like, having bought other machines off them over the years,” Kelvin explained.

Having had no GPS system on any tractor at the time, Kelvin sought grant aid for a GPS control unit too. To keep things straightforward, he opted to go with Amazone’s own Amatron 4 Isobus terminal which offered the flexibility of being an independent GPS or Isobus terminal, meaning it could be used for guidance or tasks, or to control other machines.

Setup

Kelvin’s spreader features a good level of specification, much of which Amazone offer as standard on its grant eligible machines. These options include a manual roll-over hopper cover (hydraulic optional), castor storage wheels, access ladder and a headland management kit.

“Although fertiliser prices are back from the highs they were at when we bought the spreader, they’re still a huge farm cost. So with this in mind, and the ongoing limitations the quantity and product types that can be spread, accuracy is critical,” he pointed out.

“For a machine that can spread with such accuracy, setup was much easier than what we initially expected. Once the blend is selected on the mySpreader app, along with the intended application rate and spread width, physically it’s just a matter of adjusting vane position. Once the desired application rate has been inputted into the terminal, the spreader automatically establishes the flowrate and constantly makes shutter adjustments relative to the tractors forward speed in order to maintain the set rate.

To date, the spreader has spread in the region of 300t trouble free.

“In hindsight, I’d have probably gone for the next hopper size up, the 2,000l will still hold four bulk bags no issue, but that extra bit of space would be welcome.

“We might look into the option of an extension at some point. When it comes to hooking it on and off, the castor wheels are a super job and the way it is designed leaves for good room between the tractor wheel and hopper to connect the PTO and hoses.”

Section control and border spreading

“Section control is a feature we wouldn’t be without now. It really takes the work out of spreading fertiliser. You couldn’t credit how accurate it is. Aside from eliminating overlap, we’ve doubled our spreading width from 12m to 24m, all the while increasing accuracy, regardless if it’s day or night,” Kelvin said.

Amazone achieves up to eight part-width section control by altering the fertiliser drop point and adjusting shutter position, while maintaining the speed of both outward turning discs.

With no guidance previously, Kelvin opted for the higher-end AmaTron 4 Isobus terminal with GPS manual guidance which was used up until the arrival of a new John Deere 6R130 early last year. Being a full spec machine with Deere’s own Greenstar guidance and Autotrac autosteer along with Isobus, he has since chosen to plug the spreaders Isobus cable directly into the tractors socket and operate the spreader via John Deere’s guidance and Isobus terminal.

“The Amatron 4 terminal is a user-friendly system and does work very well. However, now that the new tractor has its own Isobus terminal and guidance, it leaves hooking on and off the spreader much quicker and removes the need for an extra terminal in the cab. That’s really the only reason we’ve since stuck with Isobus,” Kelvin said.

The spreader is equipped with the electrically adjustable Limiter V+ border spreading kit. From the terminal, border and watercourse spreading modes can be selected with the touch of a button. These presets change the degree in which the deflector kit is lowered.

Calibration and build quality

As part of the offer at the time, the spreader came with Amazone’s EasyCheck calibration mats. Essentially, the mats are a digital version of traditional trays used for tray test calibrations. Once the mats have been laid out and the spreader has passed over them, each mat is photographed through the mySpreader app, where the results are analysed. The operator is then notified of any necessary setting changes.

Kelvin finds the mats a great job and a much faster way of calibrating the spreader in comparison to trays. They’re much easier stored which is a bonus too, he said.

“With the exception of some Nitro Fert products, pretty much all the fertilisers we have used so far are on the Amazone database, which leaves setup quick and easy when going between products.”

Amazone (like most manufacturers) offers a service whereby customers can send samples of a particular blend or product direct to its factory for analysis, where it will then be available on the app.

Being a Profis spreader means it is equipped with a twin-cell weighing system which was also a key selling point for Kelvin: “With all our paddocks mapped on Pasture Base, I know quickly how many kilograms are needed for a particular paddock before leaving the yard and know that when I return empty, the paddock has got what was required, no more, no less.”

Now entering its fourth working season rust free, Kelvin is very impressed with both build and paint quality. That said, he is meticulous with how the spreader is maintained. After use, it is washed thoroughly and stored indoors. Before winter storage it is also sprayed with oil and stored uncover.

Savings

Now spreading with full GPS autosteer and section control, the Kellys are confident in knowing that each paddock is evenly and accurately spread, noting a big improvement in how even their grass covers are.

“It’s a combination of a more accurate spread pattern, the section control, weigh cells and the headland kit. On a paddock-by-paddock basis there are fertiliser savings. However, it’s a hard one to quantify by just how much having not had weigh cells previously and taking into account that overlaps don’t necessarily always translate to a complete loss of product, it’s more inefficient use of product.

“I suppose you could say that if there’s less overlap, soil fertility is bound to be more consistent too. Even if there was only one tonne of protected urea being saved per year by reducing overlaps, etc. At a cost of €550/tonne, then there’s an noticeable saving.”

Verdict

About to enter their fourth season with the spreader, the Kellys are delighted with how it has performed and the results.

“We spread in the region of 100t annually, that’s including what we spread for an uncle. So after 300t, the spreader hasn’t missed a beat.

“Between how easy it is set up and used, along with the section control and headland kit, the work has been taken out of spreading fertiliser and has left it a job that can be done any time of the day or night, with a guarantee of accurate results.

“Honestly, it’s a machine we probably wouldn’t have invested in without grant aid, purely down to cost. But now used to what it is capable of, I don’t think it’s a machine that we would be without,” Kelvin added.

Likes

Ease of use.Storage wheels.Accuracy. Dislikes

Along with an extra step on the access ladder, one on both sides would be a benefit.Spec

Model: ZA-V 2600 Profis Tronic. Spread width: 10 to 36m. Hopper capacity: 2,000l. Empty weight: 366kg. Drive type: PTO.Section control method: drop point and shutter adjustment. List price: €24,000 plus VAT. (Isobus ready).

Since the arrival of a new full spec John Deere 6R130, Kelvin operates the spreader via Isobus.

Kelvin would have liked to have an access ladder on both sides of the hopper.

Amazone achives its eight-part width section control by altering fertiliser flow rate and drop point.

The 2,000l hopper will hold four bulk bags comfortably.

Kelvin initially used the Amatron 4 terminal for the control of the spreader, as well as GPS guidance and section control.

SHARING OPTIONS