The Irish Farmers Journal recently visited the Hughes family farm in Carnew, Co Wicklow, where they have just completed over a month’s milking in their new 54- bail Pearson International rotary parlour.

Joseph Jr farms in partnership with his father Joseph Sr and mother Elma, but it is very much a family affair, with his sister Helen and brother Andy helping out in their spare time.

The Hughes family run a tight ship, milking in the region of 300 Friesian cows on 400ac, between owned and rented land. Their plan is to grow the herd this year and calve down 350 cows.

They milk all year round, operating 100% AI.

The herd is calved in October for four weeks and again in February for 12 weeks.

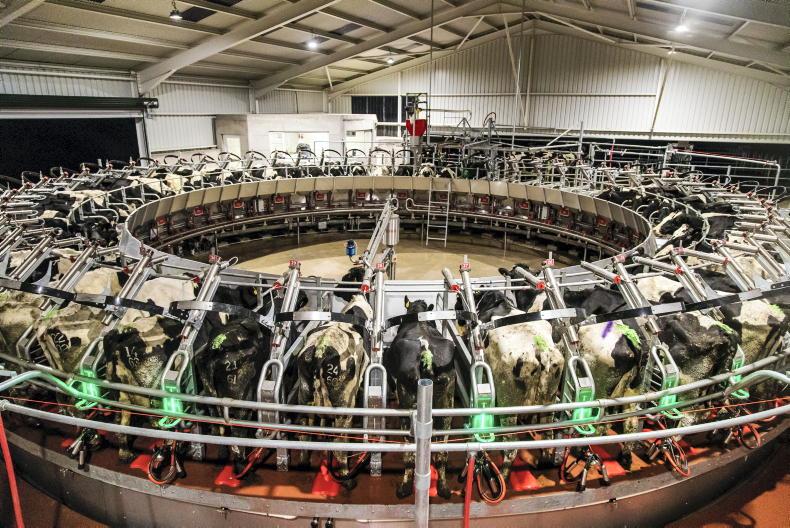

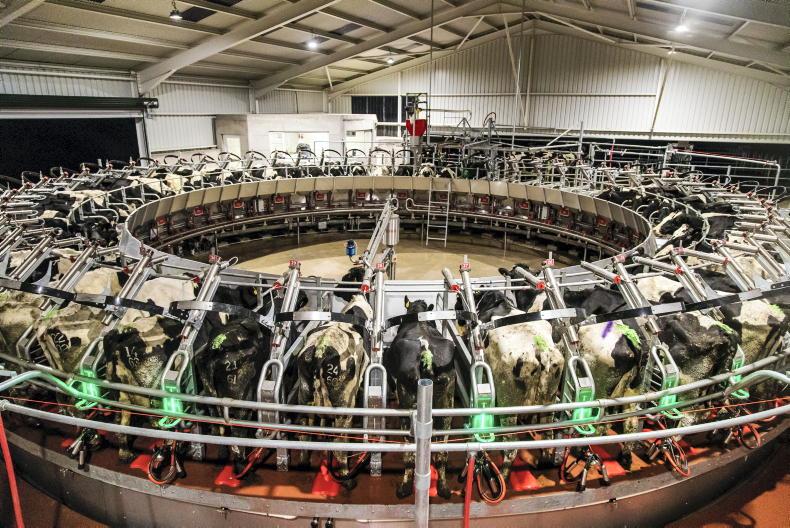

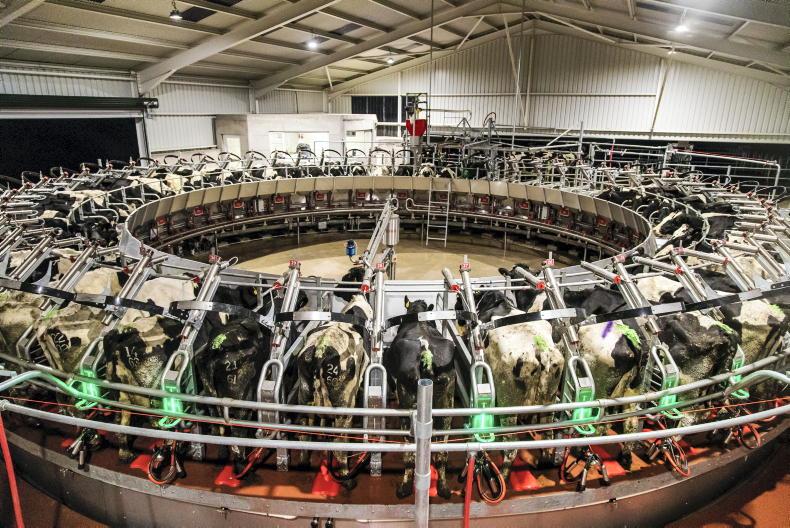

Bird's-eye view of the 54-bail rotary parlour. \ Claire Nash

In the past, the father-and-son duo would have thrown their hand at contracting, beef, sheep and tillage, but they have reined back on these aspects of the business in the past five years, to focus on expanding their dairy herd.

Originally milking 280 cows in a 16-unit herringbone parlour with a collecting yard suitable for just 80 cows, it was taking nine hours a day to milk at peak milking.

Joseph Jr says: “We would have been milking 160 cows and everything was perfect. We started expanding in 2017 and numbers started to climb up. We discovered a few problems. One [of the problems] was the milking parlour and accommodation, so in 2018 we put in 200 topless cubicles which was a big help, but as the numbers kept growing it was evident that we had to do something with the parlour.”

Drafting system and footbath at the exit of the rotary parlour. \ Claire Nash

Doing the research

Having done extensive research in Ireland, New Zealand and Australia, the family made the decision that they were going to choose a rotary parlour, and purchased the Pearson International machine.

“We wanted to milk with a one-man system. We knew the 54-bail rotary is renowned around the world as the best parlour for one man and the most economical for one person to milk in,” Joseph Jr says.

Excavation

After getting approval from the banks and for planning permission on a greenfield site last spring, the excavation work began on 3 April last year and was carried out by the Dagg Brothers of Carnew.

To keep costs down, the Hughes family did as much work as possible themselves, along with the help of neighbours and friends. There was a 28-day operation of digging out non-stop, with many parts of the field requiring a 20ft dig in order to achieve a level site.

Construction work

Ray Byrne Construction carried out the full works of the project, from the fabrication and erection of the shed, to the concrete work. Over 800m of concrete was laid across the whole site. The building structure stands at 100ft long x 73ft wide, with all the purlins, pillars and rafters painted white, to make the parlour brighter. Phil Kavanagh completed plumbing works, while electrics were carried out by Wayne Austin Electrical.

Customised grid which is installed at the end of the rotary designed to collect cow excrement and prevent further washing. \ Claire Nash

Levels of automation

“In terms of automation, we put in a touchscreen control. It has all the information and commands at the touch of your finger. It is right behind you when you are cupping on. When a cow walks into the parlour, her electronic tag is read by the computer. You don’t have to go far to get your information and if you are not happy with a cow you can just draft her at the touch of a button. We have Texas gates going in, which lets one cow at a time on to the rotary,” Joseph Jr says.

“An automatic arm individually puts teat spray on the cows. The parlour is fitted with cluster removers, auto ID, individual feeding and you also have the option of milk separation.

“If there is anything wrong with a cow, the retention arm will stay down and she will get to come back around so you can look at her again. We installed a grid at the exit of the rotary as we find that is when cows usually do their business, it makes washing easier,” he says.

Water usage

The Hughes family were conscious of water usage, so an autowash and floodwash system was installed and all water is recycled through a series of micron filters and UV light filters seven times before it becomes soiled water. The floodwash system washes the collecting yard and drafting area with 50,000 litres of soiled water.

A collecting yard which is designed to hold 400 cows. \ Claire Nash

Rotary installation

The full project was completed just shy of six months, with Cian O’Toole of Keadeen Dairy Services undertaking the installation of the 54-bail rotary parlour. The Hughes family began milking in the first week of December 2020.

The collecting yard on the way in is designed to hold up to 400 cows. As they approach the parlour they are met by island bars. This helps prevent the bullying and squeezing of cows coming in along the way. The family find that this works well as the cows are ready facing to go into the parlour. Other features include a raised bulk tank, oil heating, drafting pens on exit, footbath, a raised office and a raised viewing area.

Happy with the project

“The biggest change we have seen is in the cows. They are much more comfortable and the parlour is much cleaner. They seem to like the motion of going around. It only took them about four days to get used to it; we couldn’t believe it. With 300 cows, each cluster is only going on six times and cows are only in the parlour for eight minutes. Everyone is happier because they are in the parlour for a shorter space of time. It’s just better for man and beast,” Joseph says.

The full project came in at €500,000 plus VAT.

The Irish Farmers Journal recently visited the Hughes family farm in Carnew, Co Wicklow, where they have just completed over a month’s milking in their new 54- bail Pearson International rotary parlour.

Joseph Jr farms in partnership with his father Joseph Sr and mother Elma, but it is very much a family affair, with his sister Helen and brother Andy helping out in their spare time.

The Hughes family run a tight ship, milking in the region of 300 Friesian cows on 400ac, between owned and rented land. Their plan is to grow the herd this year and calve down 350 cows.

They milk all year round, operating 100% AI.

The herd is calved in October for four weeks and again in February for 12 weeks.

Bird's-eye view of the 54-bail rotary parlour. \ Claire Nash

In the past, the father-and-son duo would have thrown their hand at contracting, beef, sheep and tillage, but they have reined back on these aspects of the business in the past five years, to focus on expanding their dairy herd.

Originally milking 280 cows in a 16-unit herringbone parlour with a collecting yard suitable for just 80 cows, it was taking nine hours a day to milk at peak milking.

Joseph Jr says: “We would have been milking 160 cows and everything was perfect. We started expanding in 2017 and numbers started to climb up. We discovered a few problems. One [of the problems] was the milking parlour and accommodation, so in 2018 we put in 200 topless cubicles which was a big help, but as the numbers kept growing it was evident that we had to do something with the parlour.”

Drafting system and footbath at the exit of the rotary parlour. \ Claire Nash

Doing the research

Having done extensive research in Ireland, New Zealand and Australia, the family made the decision that they were going to choose a rotary parlour, and purchased the Pearson International machine.

“We wanted to milk with a one-man system. We knew the 54-bail rotary is renowned around the world as the best parlour for one man and the most economical for one person to milk in,” Joseph Jr says.

Excavation

After getting approval from the banks and for planning permission on a greenfield site last spring, the excavation work began on 3 April last year and was carried out by the Dagg Brothers of Carnew.

To keep costs down, the Hughes family did as much work as possible themselves, along with the help of neighbours and friends. There was a 28-day operation of digging out non-stop, with many parts of the field requiring a 20ft dig in order to achieve a level site.

Construction work

Ray Byrne Construction carried out the full works of the project, from the fabrication and erection of the shed, to the concrete work. Over 800m of concrete was laid across the whole site. The building structure stands at 100ft long x 73ft wide, with all the purlins, pillars and rafters painted white, to make the parlour brighter. Phil Kavanagh completed plumbing works, while electrics were carried out by Wayne Austin Electrical.

Customised grid which is installed at the end of the rotary designed to collect cow excrement and prevent further washing. \ Claire Nash

Levels of automation

“In terms of automation, we put in a touchscreen control. It has all the information and commands at the touch of your finger. It is right behind you when you are cupping on. When a cow walks into the parlour, her electronic tag is read by the computer. You don’t have to go far to get your information and if you are not happy with a cow you can just draft her at the touch of a button. We have Texas gates going in, which lets one cow at a time on to the rotary,” Joseph Jr says.

“An automatic arm individually puts teat spray on the cows. The parlour is fitted with cluster removers, auto ID, individual feeding and you also have the option of milk separation.

“If there is anything wrong with a cow, the retention arm will stay down and she will get to come back around so you can look at her again. We installed a grid at the exit of the rotary as we find that is when cows usually do their business, it makes washing easier,” he says.

Water usage

The Hughes family were conscious of water usage, so an autowash and floodwash system was installed and all water is recycled through a series of micron filters and UV light filters seven times before it becomes soiled water. The floodwash system washes the collecting yard and drafting area with 50,000 litres of soiled water.

A collecting yard which is designed to hold 400 cows. \ Claire Nash

Rotary installation

The full project was completed just shy of six months, with Cian O’Toole of Keadeen Dairy Services undertaking the installation of the 54-bail rotary parlour. The Hughes family began milking in the first week of December 2020.

The collecting yard on the way in is designed to hold up to 400 cows. As they approach the parlour they are met by island bars. This helps prevent the bullying and squeezing of cows coming in along the way. The family find that this works well as the cows are ready facing to go into the parlour. Other features include a raised bulk tank, oil heating, drafting pens on exit, footbath, a raised office and a raised viewing area.

Happy with the project

“The biggest change we have seen is in the cows. They are much more comfortable and the parlour is much cleaner. They seem to like the motion of going around. It only took them about four days to get used to it; we couldn’t believe it. With 300 cows, each cluster is only going on six times and cows are only in the parlour for eight minutes. Everyone is happier because they are in the parlour for a shorter space of time. It’s just better for man and beast,” Joseph says.

The full project came in at €500,000 plus VAT.

SHARING OPTIONS