I got the opportunity to travel to Sweden last week to visit the DeLaval headquarters in Tumba as part of their newly expanded Hamra farm inauguration.

The headquarters is broken up into two sections. The first leg of our visit was to the main factory where the majority of DeLaval products are constructed.

The second, was to the new Hamra dairy farm where DeLaval trial all new technology and products in a real farm setting before they go to market.

The entirety of the visit was like a step into the future with automation the name of the game, in both the factory and on the farm.

DeLaval

The organisation was initially founded in Sweden in the late-1800s with the primary goal of producing machinery and milking equipment capable of pushing farms to the next level.

Their efforts in recent years, particularly on the continent has centred around delivering more automated solutions for dairy farmers.

Robots are becoming the norm across mainland European countries where cows are primarily milked all-year-round in a confined system. Labour shortages have also led to a huge surge in their popularity.

Many of these farms were traditionally milking three times a day through herringbone parlours which were operated throughout the day and night.

Robots offer a strong alternative to this by cutting down the need for additional staff and reducing the working hours with more and more farmers investing by the day.

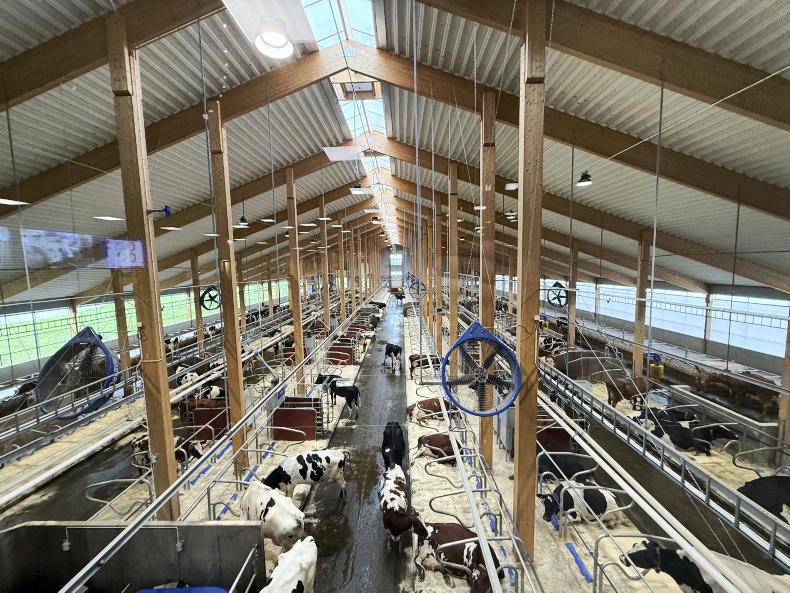

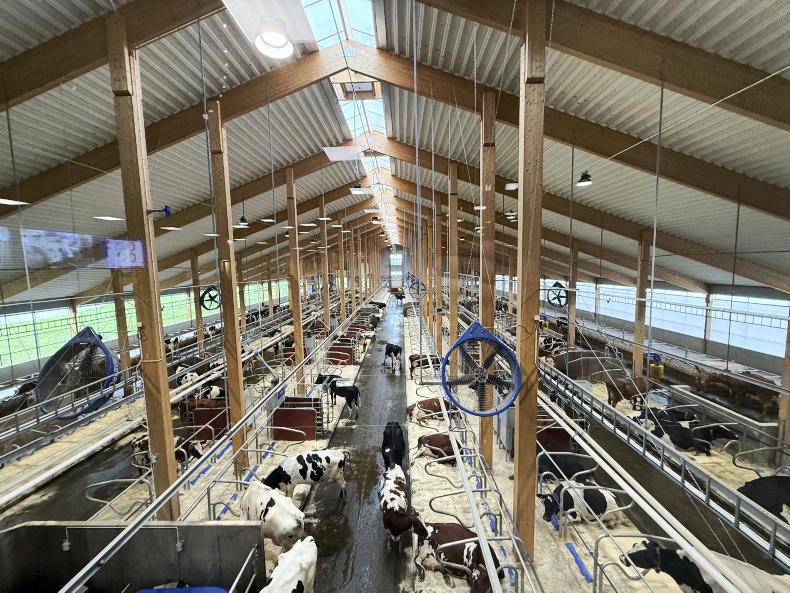

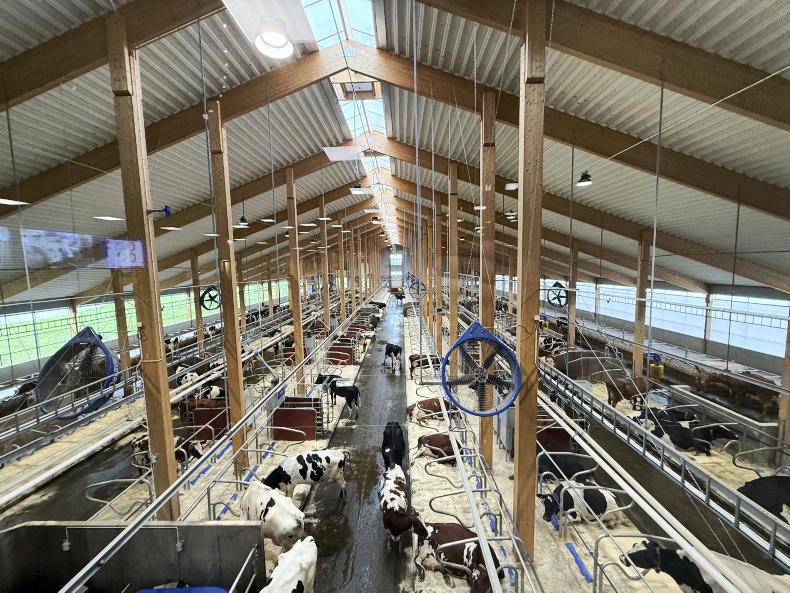

View of the cows in the new shed on the Hamra farm.

Batch System

An interesting development DeLaval are looking at to overcome the issues outlined above is a robotic batch milking system.

In the batch scenario a farmer has a number of robots built around a collecting yard. The collecting yard is similar to the standard set-up on Irish farms. Cows are then brought to the yard in groups and milked two or three times a day.

This is being practiced on some farms in Australia where herds are larger and farms are operating grass-based systems.

For example, one of those farms has 600 cows and 15 DeLaval robots in the batch system. Cows are brought to the yard in groups of 150 at a time, each robot milks 10 cows and the milking for that group is finished in 70 minutes.

The only labour required for milking is in bringing groups of cows to the collecting yard and letting them back to the paddock.

This would mean managing different groups of cows but the advantage is that one operator could manage a far greater number of cows.

In an Irish context, a farm with 200 cows might have four groups of 50 cows with five robots in the batch system.

Hamra Farm

The main part of the visit was to the DeLaval commercial farm known as Hamra farm which has seen significant investment and growth in the last 12 months.

This farm was set up as a way of carrying out research and development with all new DeLaval staff across Europe trained here.

They have expanded the capacity of the farm from 250 cows up to 500+ cows.

The main development was a new shed with capacity for 350 cows operating five robots. These new robots have the capacity to milk 75 cows each at just over seven minutes per cow.

They’ve also incorporated an automatic feeding system known as the Optimat feeding system.

The Optimat automatic feed system on the farm. The two feeder wagons are loaded by the conveyor belt on the mixer.

This machine is loaded up with silage, maize, straw and concentrates. This feed then enters a mixer. Once the feed has been mixed appropriately the machine will load up a pair of automatic feeding wagons which then distribute feed to the cows.

This machine is loaded once but serves feed to cows throughout the day to make sure there’s always fresh feed available. According to DeLaval representatives, this has increased dry matter consumption by a couple of kilos per day which is important in their high-input high-output system.

All of this was viewed from above, in the newly constructed visitor centre which lies inside the shed. The centre has 360 degree views of the shed through clear glass.

One could be forgiven for thinking the entire building was something from a movie in the year 2050. Automatic scrapers were moving silently around the shed constantly throughout the visit while an automatic cubicle bedding system kicked into operation on several occasions.

The visit really showcased how rapidly technology is evolving, and it’s only a matter of time before we have a lot more of it on our farms.

A DeLaval automatic scraper is constantly cleaning the ground under the cows.

This article was updated on 10 October 2025

I got the opportunity to travel to Sweden last week to visit the DeLaval headquarters in Tumba as part of their newly expanded Hamra farm inauguration.

The headquarters is broken up into two sections. The first leg of our visit was to the main factory where the majority of DeLaval products are constructed.

The second, was to the new Hamra dairy farm where DeLaval trial all new technology and products in a real farm setting before they go to market.

The entirety of the visit was like a step into the future with automation the name of the game, in both the factory and on the farm.

DeLaval

The organisation was initially founded in Sweden in the late-1800s with the primary goal of producing machinery and milking equipment capable of pushing farms to the next level.

Their efforts in recent years, particularly on the continent has centred around delivering more automated solutions for dairy farmers.

Robots are becoming the norm across mainland European countries where cows are primarily milked all-year-round in a confined system. Labour shortages have also led to a huge surge in their popularity.

Many of these farms were traditionally milking three times a day through herringbone parlours which were operated throughout the day and night.

Robots offer a strong alternative to this by cutting down the need for additional staff and reducing the working hours with more and more farmers investing by the day.

View of the cows in the new shed on the Hamra farm.

Batch System

An interesting development DeLaval are looking at to overcome the issues outlined above is a robotic batch milking system.

In the batch scenario a farmer has a number of robots built around a collecting yard. The collecting yard is similar to the standard set-up on Irish farms. Cows are then brought to the yard in groups and milked two or three times a day.

This is being practiced on some farms in Australia where herds are larger and farms are operating grass-based systems.

For example, one of those farms has 600 cows and 15 DeLaval robots in the batch system. Cows are brought to the yard in groups of 150 at a time, each robot milks 10 cows and the milking for that group is finished in 70 minutes.

The only labour required for milking is in bringing groups of cows to the collecting yard and letting them back to the paddock.

This would mean managing different groups of cows but the advantage is that one operator could manage a far greater number of cows.

In an Irish context, a farm with 200 cows might have four groups of 50 cows with five robots in the batch system.

Hamra Farm

The main part of the visit was to the DeLaval commercial farm known as Hamra farm which has seen significant investment and growth in the last 12 months.

This farm was set up as a way of carrying out research and development with all new DeLaval staff across Europe trained here.

They have expanded the capacity of the farm from 250 cows up to 500+ cows.

The main development was a new shed with capacity for 350 cows operating five robots. These new robots have the capacity to milk 75 cows each at just over seven minutes per cow.

They’ve also incorporated an automatic feeding system known as the Optimat feeding system.

The Optimat automatic feed system on the farm. The two feeder wagons are loaded by the conveyor belt on the mixer.

This machine is loaded up with silage, maize, straw and concentrates. This feed then enters a mixer. Once the feed has been mixed appropriately the machine will load up a pair of automatic feeding wagons which then distribute feed to the cows.

This machine is loaded once but serves feed to cows throughout the day to make sure there’s always fresh feed available. According to DeLaval representatives, this has increased dry matter consumption by a couple of kilos per day which is important in their high-input high-output system.

All of this was viewed from above, in the newly constructed visitor centre which lies inside the shed. The centre has 360 degree views of the shed through clear glass.

One could be forgiven for thinking the entire building was something from a movie in the year 2050. Automatic scrapers were moving silently around the shed constantly throughout the visit while an automatic cubicle bedding system kicked into operation on several occasions.

The visit really showcased how rapidly technology is evolving, and it’s only a matter of time before we have a lot more of it on our farms.

A DeLaval automatic scraper is constantly cleaning the ground under the cows.

This article was updated on 10 October 2025

SHARING OPTIONS