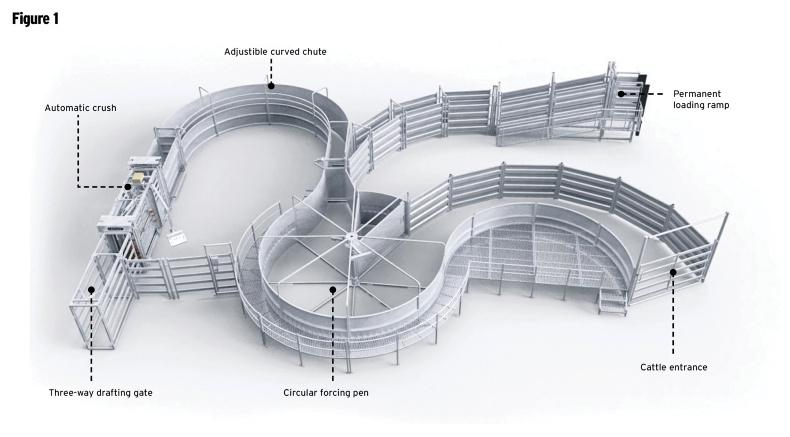

Having a well-designed handling unit on the farm is crucial for the safe handling of cattle throughout the year.

According to the Health and Safety Authority (HSA), the essential components of good yards include the collecting pen, the race, the forcing pen, raised catwalks alongside the race, crush, skulling gate, dispersal pen and worker escape points, all with gates that swing and latch freely.

When designing a handling yard, the layout should always ensure an escape route for the handler. With the opening of the TAMS II options, many farmers are considering building a new handling unit. Farmers building such a unit under TAMS should make themselves aware of the specifications required. Sometimes farmers feel Department specifications are very onerous, but many of the specifications are there for farmers’ safety.

All the specifications are available on the Department’s website under the farm buildings section. Remember, planning permission is required before a TAMS II application can be made. In this series of photos, we cover the main design aspects farmers should consider before building animal-handling facilities to make sure they are as safe as possible but also meet Department grant specifications.

Pictures one, two

and three

The crush is an important area to get right in the design. It should be long enough to hold the animal without its head in the headbail. In the crush pictured, the farmer can easily hold the animal in place using a steel tail bar and non-return flaps.

Picture 1

If the animal is short, the steel tail bar can be pushed forward section by section and the non-return flaps will prevent it from going backwards if the animal exerts reverse pressure. According to the Department, all uprights must be of tubular steel at least 76mm outer diameter, 5mm thick, or hollow section steel 80x80x4mm thick.

Picture 2

Uprights must be fitted in a 300x300x450mm concrete base at no more than 2.3m apart (centre to centre) except the skulling gate section, which must be at no more than 1.8m apart and preferably 1.4m (centre to centre). Head scoops like the one pictured are covered in the scheme.

Picture 3

All rails or sections in the race must be fitted with a quick-release mechanism so that they can be removed safely in case an animal becomes trapped or goes down in the race.

The Department recommends that races have a sliding gate (like the one pictured) or hinged gate at the back to prevent animals from reversing back into the forcing pen. The race length should be a minimum of 3.6m and the recommended length is 5.4m. A 9m race would hold five to six adult cattle and the Department is not in favour of races holding 12 or more animals at one time.

Picture four

Raised catwalks can really help when working with animals in the race. A raised catwalk allows the handler to have increased reach for administrating animal remedies, testing or carrying out any other livestock treatment.

Picture 4

The Department is in favour of catwalks and recommends that they are incorporated in the design to run along the race. To meet specifications they must be 300 to 400mm high and not less than 1.1m wide to facilitate a safe working area. Variable height catwalks are also allowed.

Picture five

When concrete is wet and dirty it can result in a very slippery surface for both man and beast. Frost and ice build-up in the winter months can also be lethal on concrete floors. That is why when designing the floor of a cattle-handling yard, it should be done in a way that reduces the chances of slipping, such as incorporating grooves.

Picture 5

For TAMS II, the floor of the handling enclosure must be a concrete slab 125mm thick over a 150mm hardcore base. The concrete must be finished with a non-slip finish or diagonal grooves at 100mm intervals to prevent animals slipping. A slope of one in 60 must be incorporated into the floor to prevent water build-up. It is also important to know that if the area is not cleaned following each use, drainage channels must be positioned in suitable locations throughout the enclosure and the effluent must be collected in an approved effluent tank.

Picture six

Well-designed forcing pens can really reduce the work involved in coaxing an animal into the race. In the forcing pen in picture six, the end of the pen is curved. Right-angled turns are inappropriate because cattle tend to follow the leader and if they lose sight of the leader they will more than likely stop in their tracks.

Picture 6

Curved or gentle angles prevent animals packing into a corner and improve flow and movement. The plastic boarding along one side helps to reduce the chances of animals in adjacent pens influencing the behaviour of cattle in the forcing pen. To comply with TAMS II standards, the forcing pen must be funnel-shaped, with one side of the funnel being straight. The other side must be at a 30° angle to the race to facilitate the ease of movement for the cattle.

Picture seven

Slip-throughs or escape points make life far easier when handing cattle in a crush and yard. They are ideal for allowing the handler quick access from one pen to another. They also provide the handler a safe getaway point if needed.

Picture 7

The Department says at least one slip-through must be provided in all holding pens if building to TAMS II specifications. The slip-through must be no more than 325mm wide according to the Department.

A well-designed cattle crush and yard makes livestock handling far safer.Catwalks increase the handler’s reach at the race and crush.Plenty of slip-throughs should be incorporated into the design for improved work efficiency and safety.Avoid right angles in the forcing pen and race entrance.There is TAMS II grant aid available for cattle crushes, races and enclosures but the specifications have to be met. Read more

Safety is a lifestyle, not a slogan

2017 a horrific year for farm safety

The economy and age factors in farm deaths

All the coverage from Farm Safety Week 2017

Having a well-designed handling unit on the farm is crucial for the safe handling of cattle throughout the year.

According to the Health and Safety Authority (HSA), the essential components of good yards include the collecting pen, the race, the forcing pen, raised catwalks alongside the race, crush, skulling gate, dispersal pen and worker escape points, all with gates that swing and latch freely.

When designing a handling yard, the layout should always ensure an escape route for the handler. With the opening of the TAMS II options, many farmers are considering building a new handling unit. Farmers building such a unit under TAMS should make themselves aware of the specifications required. Sometimes farmers feel Department specifications are very onerous, but many of the specifications are there for farmers’ safety.

All the specifications are available on the Department’s website under the farm buildings section. Remember, planning permission is required before a TAMS II application can be made. In this series of photos, we cover the main design aspects farmers should consider before building animal-handling facilities to make sure they are as safe as possible but also meet Department grant specifications.

Pictures one, two

and three

The crush is an important area to get right in the design. It should be long enough to hold the animal without its head in the headbail. In the crush pictured, the farmer can easily hold the animal in place using a steel tail bar and non-return flaps.

Picture 1

If the animal is short, the steel tail bar can be pushed forward section by section and the non-return flaps will prevent it from going backwards if the animal exerts reverse pressure. According to the Department, all uprights must be of tubular steel at least 76mm outer diameter, 5mm thick, or hollow section steel 80x80x4mm thick.

Picture 2

Uprights must be fitted in a 300x300x450mm concrete base at no more than 2.3m apart (centre to centre) except the skulling gate section, which must be at no more than 1.8m apart and preferably 1.4m (centre to centre). Head scoops like the one pictured are covered in the scheme.

Picture 3

All rails or sections in the race must be fitted with a quick-release mechanism so that they can be removed safely in case an animal becomes trapped or goes down in the race.

The Department recommends that races have a sliding gate (like the one pictured) or hinged gate at the back to prevent animals from reversing back into the forcing pen. The race length should be a minimum of 3.6m and the recommended length is 5.4m. A 9m race would hold five to six adult cattle and the Department is not in favour of races holding 12 or more animals at one time.

Picture four

Raised catwalks can really help when working with animals in the race. A raised catwalk allows the handler to have increased reach for administrating animal remedies, testing or carrying out any other livestock treatment.

Picture 4

The Department is in favour of catwalks and recommends that they are incorporated in the design to run along the race. To meet specifications they must be 300 to 400mm high and not less than 1.1m wide to facilitate a safe working area. Variable height catwalks are also allowed.

Picture five

When concrete is wet and dirty it can result in a very slippery surface for both man and beast. Frost and ice build-up in the winter months can also be lethal on concrete floors. That is why when designing the floor of a cattle-handling yard, it should be done in a way that reduces the chances of slipping, such as incorporating grooves.

Picture 5

For TAMS II, the floor of the handling enclosure must be a concrete slab 125mm thick over a 150mm hardcore base. The concrete must be finished with a non-slip finish or diagonal grooves at 100mm intervals to prevent animals slipping. A slope of one in 60 must be incorporated into the floor to prevent water build-up. It is also important to know that if the area is not cleaned following each use, drainage channels must be positioned in suitable locations throughout the enclosure and the effluent must be collected in an approved effluent tank.

Picture six

Well-designed forcing pens can really reduce the work involved in coaxing an animal into the race. In the forcing pen in picture six, the end of the pen is curved. Right-angled turns are inappropriate because cattle tend to follow the leader and if they lose sight of the leader they will more than likely stop in their tracks.

Picture 6

Curved or gentle angles prevent animals packing into a corner and improve flow and movement. The plastic boarding along one side helps to reduce the chances of animals in adjacent pens influencing the behaviour of cattle in the forcing pen. To comply with TAMS II standards, the forcing pen must be funnel-shaped, with one side of the funnel being straight. The other side must be at a 30° angle to the race to facilitate the ease of movement for the cattle.

Picture seven

Slip-throughs or escape points make life far easier when handing cattle in a crush and yard. They are ideal for allowing the handler quick access from one pen to another. They also provide the handler a safe getaway point if needed.

Picture 7

The Department says at least one slip-through must be provided in all holding pens if building to TAMS II specifications. The slip-through must be no more than 325mm wide according to the Department.

A well-designed cattle crush and yard makes livestock handling far safer.Catwalks increase the handler’s reach at the race and crush.Plenty of slip-throughs should be incorporated into the design for improved work efficiency and safety.Avoid right angles in the forcing pen and race entrance.There is TAMS II grant aid available for cattle crushes, races and enclosures but the specifications have to be met. Read more

Safety is a lifestyle, not a slogan

2017 a horrific year for farm safety

The economy and age factors in farm deaths

All the coverage from Farm Safety Week 2017

SHARING OPTIONS