TAMS tranche 10 remains open until 5 December, and with drystock farmers in particular benefitting from high commodity prices, there is an anticipation that spending on farms will increase to reduce tax bills.

As part of its ongoing review on specifications for animal handling and farm building facilities, the Department recently updated specifications with regard to two areas: pig housing and mobile sheep-handling facilities.

Upgrades to pig housing/slatted floor replacement

Changes were made to S145 (upgrading pig houses) and S123S (replacement of slats), both of which contain much the same detail regarding farrowing pen minimum specifications.

For farrowing pens a minimum of 1.3m² of the floor area of the farrowing pen should be a continuous solid floor area and a further 1.3m² of the floor area of the pen should be either continuous solid floor or slatted floor with total openings not exceeding 10% of this floor area (a drained floor), giving a total minimum floor area of 2.6m² , a combination of fully solid and drained floor.

The remainder of the pen may be fully slatted. For a 6.5m² pen this equates to a minimum 20% solid floor area and a maximum 60% fully slatted area. It is recommended by the Department that the solid floor area is at least 30% of the pen area and the slatted floor area does not exceed 50% of the pen area, with the remainder of the pen area being drained floor.

The piglet lying area should be a continuous solid floor area of 1.2m² and is included in the 1.3m² solid floor requirement. The sow lying area, both when confined and when loose, is recommended to be either continuous solid flooring or drained flooring, with perforations not exceeding 10%.

A small change has also been added to S145 regarding trough feed space in pig units. Where pigs are fed at discrete intervals during the day “irrespective of the number of times”, it notes as part of the change, with the trough being of sufficient length for all the pigs in the pen to feed at the same time when the pigs are at their maximum size in the pen. It also notes that “the feed distribution system shall ensure that the feed is distributed along the full length of the troughs”. A recommended trough length based on pig size is seen in Table 1.

Grant aid under the PPIS will only be paid on approved, completed and eligible expenditure, and shall be paid at the rate of 40%, up to the applicable TAMS III PPIS maximum investment ceiling of €500,000. This ceiling includes the €90,000 ceiling available in the other seven TAMS III schemes and is in addition to the stand-alone ceilings for the Lower Emission Slurry Scheme (LESS) and the Solar Capital Investment Scheme (SCIS). Use of this investment ceiling will reduce the €90,000 investment ceiling for all other TAMS III schemes, with the exception of LESS and SCIS.

Mobile sheep-handling facilities

Mobile sheep-handling facilities have proven popular among farmers for two reasons: firstly, because they fall under the Farm Safety Capital Investment Scheme (FSCIS) and, therefore, qualify for 60% grant aid for all farmers, but also because they are easy to apply for, with no planning permissions or exemptions required.

S136A (mobile sheep handling facilities) received some minor updates of late which are listed below.

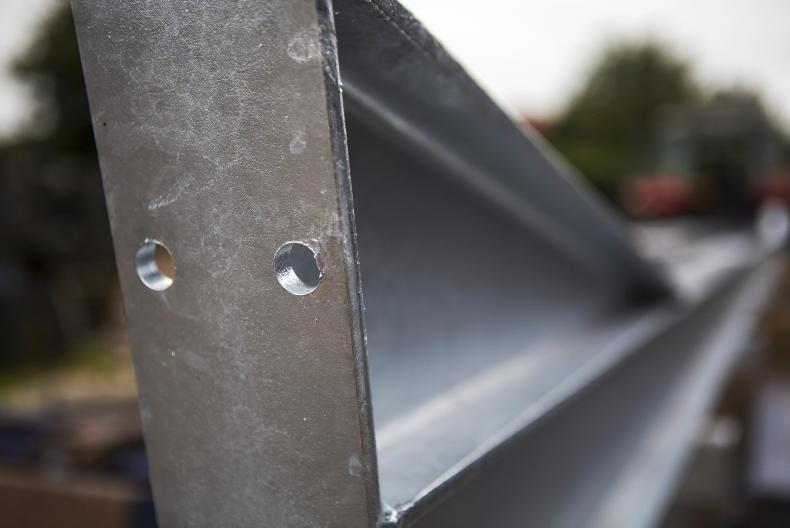

The wheels [on a mobile sheep-handling unit] should be suitable to enable the unit to be towed on public roads, gravel roads and across fields behind a vehicle. The unit is also required to have lights and relevant plating for use on public roads.The unit may have a footbath. This does not mean that one is required, but it can be included within the race, with this being covered when not in use. This is different to a “batch footbath”, which is separate from the handling unit and is capable of holding eight to 16 sheep.Mobile penning should be at least 850mm high, but it is strongly recommended that it be 970mm high and with a minimum of six rails. A new change to the specification is that where there are less than six rails, the penning can be sheeted for the full height or a combination of rails and sheeting used. Each penning section must also have a facility for connecting to other penning sections ie drop pins with lugs.It is worth noting that site ownership/lease is required in regard to fixed handling investments, but not for mobile investments.

The serial number of the portable sheep handling race with wheels on it requires a serial number to be provided, so this rules out manufacturing a homemade unit.

TAMS tranche 10 remains open until 5 December, and with drystock farmers in particular benefitting from high commodity prices, there is an anticipation that spending on farms will increase to reduce tax bills.

As part of its ongoing review on specifications for animal handling and farm building facilities, the Department recently updated specifications with regard to two areas: pig housing and mobile sheep-handling facilities.

Upgrades to pig housing/slatted floor replacement

Changes were made to S145 (upgrading pig houses) and S123S (replacement of slats), both of which contain much the same detail regarding farrowing pen minimum specifications.

For farrowing pens a minimum of 1.3m² of the floor area of the farrowing pen should be a continuous solid floor area and a further 1.3m² of the floor area of the pen should be either continuous solid floor or slatted floor with total openings not exceeding 10% of this floor area (a drained floor), giving a total minimum floor area of 2.6m² , a combination of fully solid and drained floor.

The remainder of the pen may be fully slatted. For a 6.5m² pen this equates to a minimum 20% solid floor area and a maximum 60% fully slatted area. It is recommended by the Department that the solid floor area is at least 30% of the pen area and the slatted floor area does not exceed 50% of the pen area, with the remainder of the pen area being drained floor.

The piglet lying area should be a continuous solid floor area of 1.2m² and is included in the 1.3m² solid floor requirement. The sow lying area, both when confined and when loose, is recommended to be either continuous solid flooring or drained flooring, with perforations not exceeding 10%.

A small change has also been added to S145 regarding trough feed space in pig units. Where pigs are fed at discrete intervals during the day “irrespective of the number of times”, it notes as part of the change, with the trough being of sufficient length for all the pigs in the pen to feed at the same time when the pigs are at their maximum size in the pen. It also notes that “the feed distribution system shall ensure that the feed is distributed along the full length of the troughs”. A recommended trough length based on pig size is seen in Table 1.

Grant aid under the PPIS will only be paid on approved, completed and eligible expenditure, and shall be paid at the rate of 40%, up to the applicable TAMS III PPIS maximum investment ceiling of €500,000. This ceiling includes the €90,000 ceiling available in the other seven TAMS III schemes and is in addition to the stand-alone ceilings for the Lower Emission Slurry Scheme (LESS) and the Solar Capital Investment Scheme (SCIS). Use of this investment ceiling will reduce the €90,000 investment ceiling for all other TAMS III schemes, with the exception of LESS and SCIS.

Mobile sheep-handling facilities

Mobile sheep-handling facilities have proven popular among farmers for two reasons: firstly, because they fall under the Farm Safety Capital Investment Scheme (FSCIS) and, therefore, qualify for 60% grant aid for all farmers, but also because they are easy to apply for, with no planning permissions or exemptions required.

S136A (mobile sheep handling facilities) received some minor updates of late which are listed below.

The wheels [on a mobile sheep-handling unit] should be suitable to enable the unit to be towed on public roads, gravel roads and across fields behind a vehicle. The unit is also required to have lights and relevant plating for use on public roads.The unit may have a footbath. This does not mean that one is required, but it can be included within the race, with this being covered when not in use. This is different to a “batch footbath”, which is separate from the handling unit and is capable of holding eight to 16 sheep.Mobile penning should be at least 850mm high, but it is strongly recommended that it be 970mm high and with a minimum of six rails. A new change to the specification is that where there are less than six rails, the penning can be sheeted for the full height or a combination of rails and sheeting used. Each penning section must also have a facility for connecting to other penning sections ie drop pins with lugs.It is worth noting that site ownership/lease is required in regard to fixed handling investments, but not for mobile investments.

The serial number of the portable sheep handling race with wheels on it requires a serial number to be provided, so this rules out manufacturing a homemade unit.

SHARING OPTIONS