The all-new Valtra Precision Lift & Load app available for G, N and T Series SmartTouch models collects data through the SmartTouch system. This weight data can then be used for invoicing purposes.

Once the weight data has been collected during the loader’s work application, the operator can transfer the data to an Excel spreadsheet afterwards for invoicing purposes, according to Valtra.

Valtra says that the new smart system can enhance work rates and improve safety.

The operator can set upper and lower lift heights and tip angles. Once the limits are reached, the loader stops automatically.

There is also a bucket shake function to make repetitive applications easier for the operator.

The app is operated from the SmartTouch touchscreen, and does not require any separate controls or displays.

The app is operated from the SmartTouch touchscreen and does not require any separate controls or displays. Changing settings within the Precision Lift & Load app is easy.

Functions for different loader tasks can be saved as profiles within the interface where a particular task can be selected from among the profiles at a later date. This allows work to commence straight away reducing setup times.

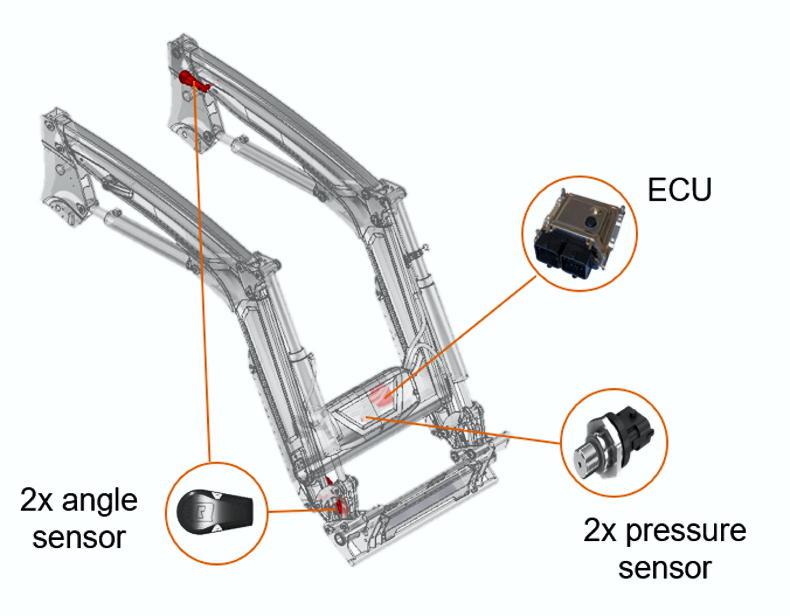

Two pressure sensors and two position sensors plus an ECU controller located inside the beam.

Measuring is done by way of two pressure sensors and two position sensors ass well as an ECU controller located inside the beam.

The SmartTouch software combines the data collected from the sensors and communicates the operator’s requirements to the front loader.

The Precision Lift & Load app will be available this autumn as a factory fit option on G, N and T Series tractors with SmartTouch armrests.

Valtra has said that the system will also be available later as a retrofit package for fifth generation SmartTouch tractors.

The all-new Valtra Precision Lift & Load app available for G, N and T Series SmartTouch models collects data through the SmartTouch system. This weight data can then be used for invoicing purposes.

Once the weight data has been collected during the loader’s work application, the operator can transfer the data to an Excel spreadsheet afterwards for invoicing purposes, according to Valtra.

Valtra says that the new smart system can enhance work rates and improve safety.

The operator can set upper and lower lift heights and tip angles. Once the limits are reached, the loader stops automatically.

There is also a bucket shake function to make repetitive applications easier for the operator.

The app is operated from the SmartTouch touchscreen, and does not require any separate controls or displays.

The app is operated from the SmartTouch touchscreen and does not require any separate controls or displays. Changing settings within the Precision Lift & Load app is easy.

Functions for different loader tasks can be saved as profiles within the interface where a particular task can be selected from among the profiles at a later date. This allows work to commence straight away reducing setup times.

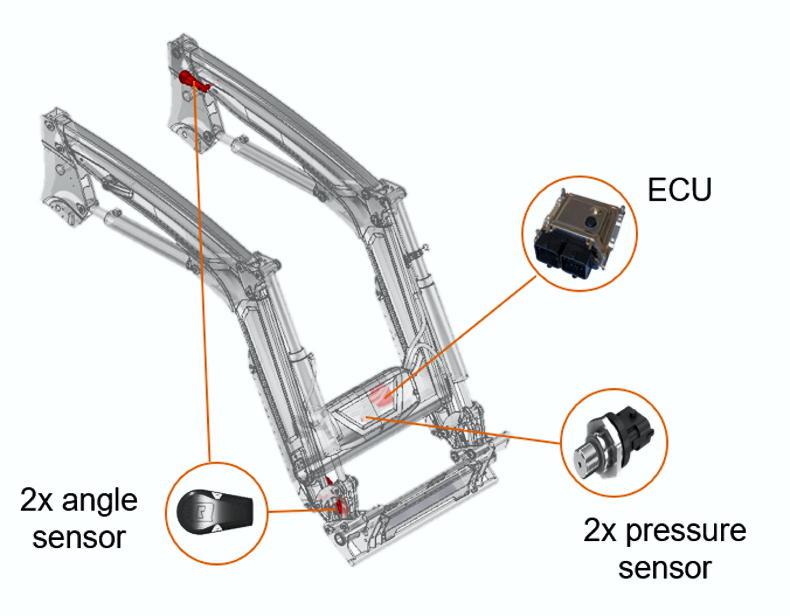

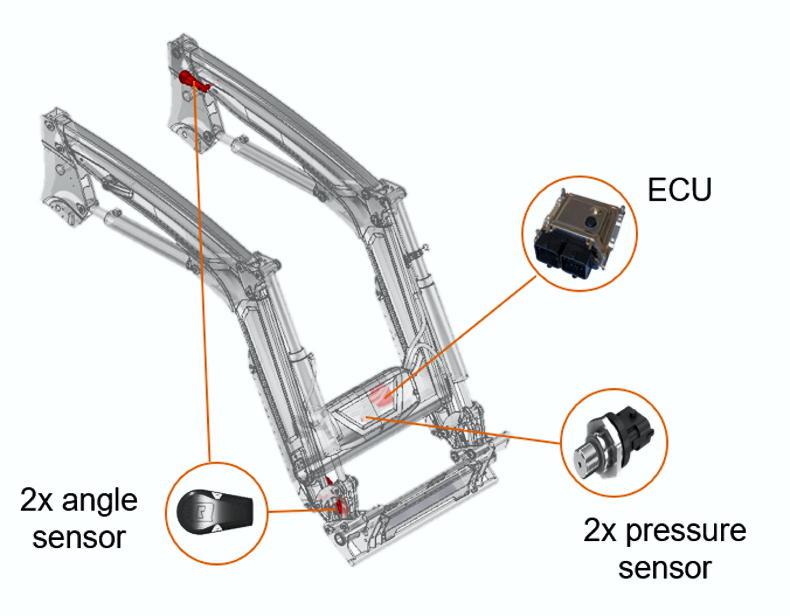

Two pressure sensors and two position sensors plus an ECU controller located inside the beam.

Measuring is done by way of two pressure sensors and two position sensors ass well as an ECU controller located inside the beam.

The SmartTouch software combines the data collected from the sensors and communicates the operator’s requirements to the front loader.

The Precision Lift & Load app will be available this autumn as a factory fit option on G, N and T Series tractors with SmartTouch armrests.

Valtra has said that the system will also be available later as a retrofit package for fifth generation SmartTouch tractors.

SHARING OPTIONS