Rhys James milks 430 cows on a 95ha milking platform near Pembrokeshire in Wales. Running a high stocking rate of 4.1 cows/ha requires lots of support ground, and Rhys has this in abundance. There is 85ha of support ground, a little less than half of the overall farm. This ground is used for silage and to rear 140 head of youngstock per year.

“The herd will average 5,500 litres or 470kg milk solids from typically 1,000kg concentrates fed through the parlour feeders on a flat-rate basis. The farm produces 14,159l/ha overall and 19,893l/ha from the milking platform with a total of 2.4m litres sold every year to Glanbia Cheese,” Rhys says.

“Last year’s comparable farm profit (CFP) showed total expenses at 17.5p/l, with a profit of 7p/l before depreciation and unpaid labour. I think we have a robust and sustainable system that can weather the storm of volatile milk prices. We benchmark our financial data in our discussion group annually and have monthly meetings to discuss relevant on-farm topics and share knowledge.”

The herd is block-calved on a grass-based system from early February until mid-April. Cows graze by day in February and are usually turned out by night in March, or when weather and grass covers allow. The herd is milked through a modern Milfos 28/56 swingover herringbone with cluster removers and an automated plant washer. Milk recording is carried out quarterly to identify high somatic cell count cows and Johne’s-positive animals. Cows tested positive for Johne’s are given red tags, inseminated to beef semen and calved separately to the rest of the herd.

Alongside Rhys, the farm has two full-time employees and a relief milker.

“The herd manager has the responsibility for herd health, calf rearing and assisting with measuring grass and using the Agrinet grass management software, while the stockman/tractor driver carries out all other stock duties as well as field work including fertiliser spreading, mowing silage, tedding and slurry work as well as farm maintenance and fencing.”

To save electricity, they installed a 50KW solar array on top of the cubicle shed roof. Rhys says it has halved the annual electric bill and the farm receives the feed-in tariff. He also installed heat-recovery units on the milk bulk tank, pre-warming the hot water heater for the parlour hot wash.

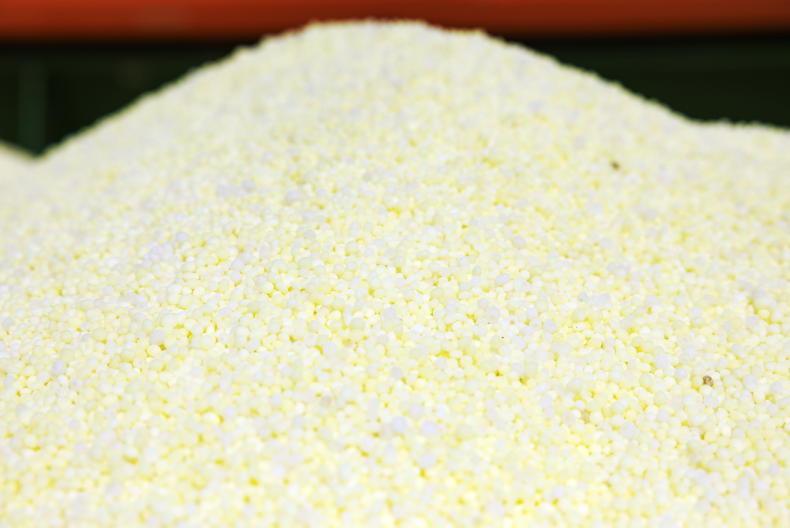

“Grass silage is picked up by a contractor but we do our own mowing and tedding. We have our own GPS-linked variable-rate fertiliser spreader. We use this to apply fertiliser to our grazing land every three to four weeks and silage area accordingly. The GPS link allows more accurate spreading and the shutters open and close automatically on the headlands and the border spreading kit means that fertiliser isn’t thrown into the hedgerows. This improves hedgerow habitat and reduces fertiliser usage,” he says.

Rainfall at the Duckspool farm is typically 1,270mm and the farm is mainly south-facing with a gentle slope on a quarter of the land. Grass growth throughout the summer is good and in 2017 the farm grew 15t DM/ha. This was from annual fertiliser usage of 250kgN/ha on the milking platform. Rhys soil-samples the farm every two years and applies phosphorus, potash and lime accordingly. He says soil fertility has also improved due to the increased stocking rate.

A big new cubicle shed was built to accommodate the cows.

“This allowed us to carry more cows on the farm and increase the stocking rate from three to four cows/ha by housing the cows by night in early spring and late autumn. The building has been a huge asset to the farm and has enabled more days in milk in the autumn. In very wet weather we can now house cows to limit poaching and soil erosion.”

Rhys James will be speaking at the Irish Grassland Association dairy conference on operating a high profit farm with medium levels of input.

SHARING OPTIONS