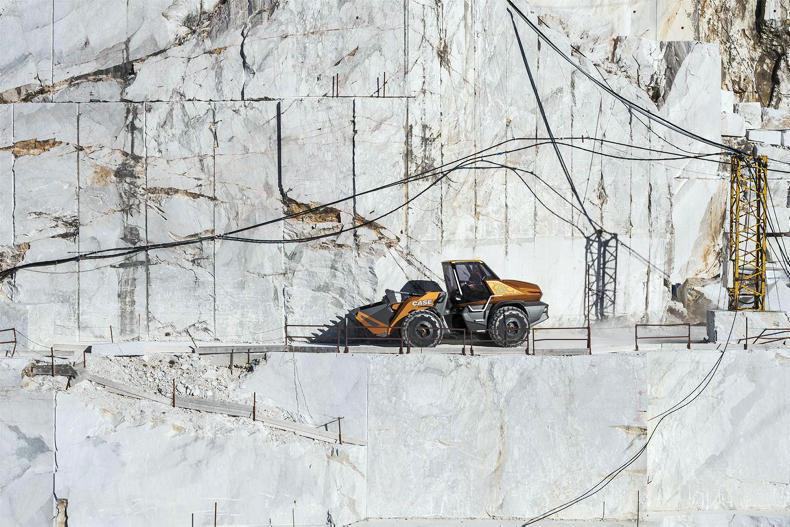

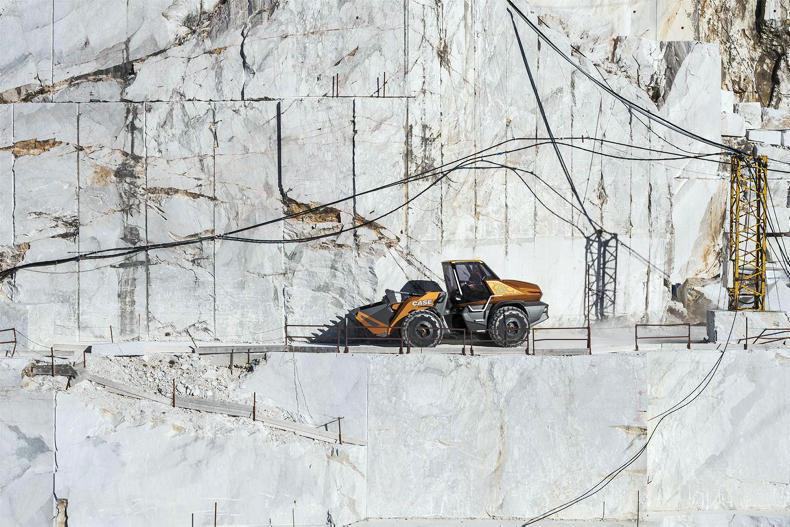

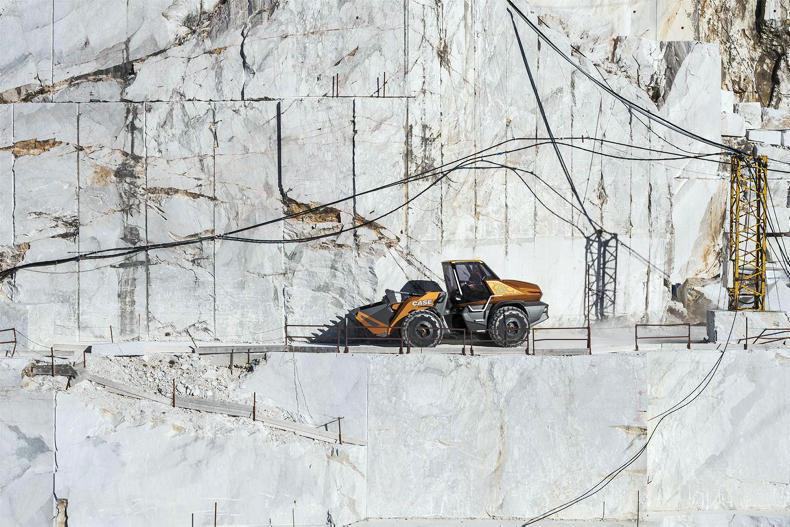

CNH Industrial recently unveiled the world’s first natural-gas powered wheel loader, branded in the Case livery. The launch took place at the Bauma show in Germany. Known as project Tetra, this concept has a design like no other wheel loader.

The wheel loader is powered by a six-cylinder NG engine from FPT Industrial’s NEF range. This engine has an output of 230hp and torque up to 1,184Nm, with the company claiming that it delivers the same power and torque as its equivalent diesel engine found in the Case 821G wheel loader, with a smoother and quieter drive.

The NG engine has fuel savings up of to 30% in comparison to its diesel counterpart.

CNH said that the methane-powered wheel loader concept produces 95% less CO2 when running on biomethane, 90% less nitrogen dioxides and 99% lower particulate matter than a diesel-powered equivalent. They added that it delivers an 80% reduction in overall emissions and also achieves a 50% reduction in drive-by noise levels.

Cab

The cab encompasses wraparound glazing with a high-visibility roof panel. Case claims this increases the total glazed area by 16% compared to a standard wheel loader. Instead of using the traditional wing mirrors, the machine is equipped with cameras.

All machine controls are accessed through two ergonomic joysticks and an integrated armrest-mounted colour touchscreen monitor.

The wheel loader is sitting on four Michelin airless concept tyres. These tyres are manufactured from pure rubber and a patented composite material in a honeycomb spoke design. The tyre-wheel fusion also has a built-in suspension. The airless tyres reduce the machine’s weight. When active, the sidewall lights are illuminated and function as an additional safety feature.

Years ahead

The level of technology on this concept machine is years ahead. The wheel loader has remote retinal scanning, accessed through any mobile device, which activates heating and cooling to adjust the cab to the optimal operating temperature.

In addition, the loader also incorporates biometric facial recognition technology to access and start-up sequences. This is to ensure that only select operators have access to the machine.

Another feature on the concept machine is integrated obstacle detection technology.

CNH Industrial recently unveiled the world’s first natural-gas powered wheel loader, branded in the Case livery. The launch took place at the Bauma show in Germany. Known as project Tetra, this concept has a design like no other wheel loader.

The wheel loader is powered by a six-cylinder NG engine from FPT Industrial’s NEF range. This engine has an output of 230hp and torque up to 1,184Nm, with the company claiming that it delivers the same power and torque as its equivalent diesel engine found in the Case 821G wheel loader, with a smoother and quieter drive.

The NG engine has fuel savings up of to 30% in comparison to its diesel counterpart.

CNH said that the methane-powered wheel loader concept produces 95% less CO2 when running on biomethane, 90% less nitrogen dioxides and 99% lower particulate matter than a diesel-powered equivalent. They added that it delivers an 80% reduction in overall emissions and also achieves a 50% reduction in drive-by noise levels.

Cab

The cab encompasses wraparound glazing with a high-visibility roof panel. Case claims this increases the total glazed area by 16% compared to a standard wheel loader. Instead of using the traditional wing mirrors, the machine is equipped with cameras.

All machine controls are accessed through two ergonomic joysticks and an integrated armrest-mounted colour touchscreen monitor.

The wheel loader is sitting on four Michelin airless concept tyres. These tyres are manufactured from pure rubber and a patented composite material in a honeycomb spoke design. The tyre-wheel fusion also has a built-in suspension. The airless tyres reduce the machine’s weight. When active, the sidewall lights are illuminated and function as an additional safety feature.

Years ahead

The level of technology on this concept machine is years ahead. The wheel loader has remote retinal scanning, accessed through any mobile device, which activates heating and cooling to adjust the cab to the optimal operating temperature.

In addition, the loader also incorporates biometric facial recognition technology to access and start-up sequences. This is to ensure that only select operators have access to the machine.

Another feature on the concept machine is integrated obstacle detection technology.

SHARING OPTIONS