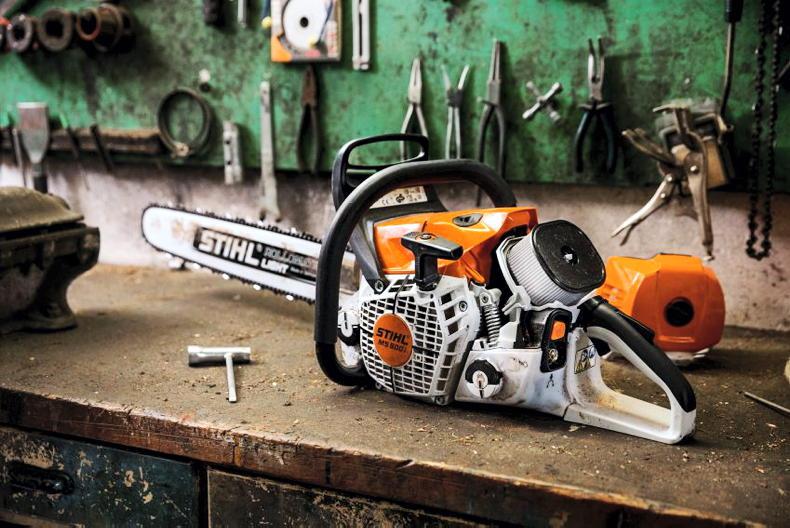

On the majority of Irish farms, a chainsaw is very much a sporadic tool, called upon in the aftermath of a storm or when a tree need to be delimbed or logged.

Chainsaws tend to be one of those tools that are put away after use and not thought about until needed once again and therefore can go in need of a service for long periods of time.

However, it is good practice to service a chainsaw once a year, or more frequently, depending on the level of usage. Here, we look at the key areas and components to consider before making a cut.

1. Spark plug

It is advised to replace the spark plug at every service. A worn-out spark plug will leave the chainsaw hard to start or fail to start in the worst scenario.

A spark plug will only cost around €5. When removing the old spark plug check its condition as this can indicate how the engine is running.

If the porcelain insulator is cracked, an electrode may be damaged or burnt. A grey colour can indicate that the piston has suffered damage.

The grey colour is caused as result of the aluminium burning within the cylinder.

Speak with your local repair specialist, if this is the case.

2. Air and fuel filter

Every service should see both the fuel and air filters replaced. For most, a fuel filter typically costs only €5 or €6. The air filter and vents should be cleaned/blown out with compressed air between services and depending on cutting conditions.

A blocked air intake could cause the saw to overheat, while a blocked air filter will smother the engine and cause it to run inefficiently or stall. Air filters will generally cost no more than €15.

It is advised to empty the fuel tank of petrol before long periods of storage. It is not uncommon for constituents of the two-stroke fuel mix ingredients to evaporate and leave behind a jelly-like residue.

If this occurs, then it may clog up the carburettor. In most cases, carburettor cleaner will resolve the issue; if not, the carburettor will need replaced.

Costing only a few Euros, the fuel filter too should be replaced at each service.

3. Sharpening a dull chain

Chain sharpening is a skill that takes considerable practice for a clean, straight cut, as replication is key between each cutter. However, it’s something the majority of people can do to improve their cuts.

When you find yourself leaning on the chainsaw to make it cut, it’s a sure indication that the chain needs sharpened.

Not only does this take longer, it uses more fuel and, over a prolonged period, will lead to chain damage and premature bar and sprocket wear. A chain can instantly lose its edge if contact with clay or a stone is made.

Regardless of the sharpening method, each cutting tooth on the chain will have a diagonal line, usually called a witness mark. This indicates the sharpening angle and marks the end of the life of the chain when filed to this point.

Chains can be sharpened manually using a file or using an electric sharpener. An electric sharpener requires the chain to be removed from the guide bar.

A simple round file is the most basic option. However, there is a two-in-one tool available that sharpens both the cutters and depth gauge (rakers) simultaneously.

Selecting a round file to sharpen the chain is not a one-size-fits-all approach. So, identify the chain size. Once the right size file has been selected, it or the two-in-one tool should be held level and at the correct angle. It then needs to be drawn from the inside of the cutter to the outside of the cutter.

Sharpen all the cutters on one side of the chain first, giving each the same number of passes (key for a straight cut), then file the cutters on the opposite side.

It should be relatively easy to see where you started, as the sharpened cutters tend to be shiny with traces of filings. As a chain is sharpened, its depth gauges need to be lowered.

The two-in-one tool does this automatically, but those using a standard round file will need to follow with a flat file and lower the rakers separately. Too low and the saw will bite too much into the timber, causing it to jump; if too high, the chainsaw will be unable to cut. If in doubt, it may be best to have the chain professionally sharpened.

A two-in-one sharpening tool is a worthwhile investment.

4. Guide bar and chain brake

The guide bar is in fact a wearing part and a component often overlooked. The track on which the chain runs needs to be kept clean for proper lubrication to take place. There is a bearing and sprocket at the top of each guide bar on which the chain rotates.

This bearing should receive grease via the small hole on the side of the bar regularly. If the chain channel has widened enough that the chain has become loose, then the bar will need to be replaced or turned upside-down. The top side will naturally wear more, so when wear just about becomes visible, turn it upside down to get that bit extra use out of it before replacement.

Chain tension is also important: too tight and it will not move freely on the guide bar, too loose and it has the possibility of coming off the bar.

It should be tightened to the point that it is just resting against the bottom side of the guide bar. Run the saw for a few minutes and recheck the tension and adjust if necessary.

The chain brake is a critical safety feature on any chainsaw and needs to be functional. It is simply a steel band around the saw’s clutch drum. Once activated, the band tightens on the clutch drum and stops the chain immediately. It is good practice to apply the brake every time the saw is left down, during sharpening or not in use. A saw with no chain brake should not be used.

5. Chain lubrication

A well-serviced saw should consume one tank of chain oil to one tank of two-stroke fuel used. It is important that dedicated chain oil is used and not burnt oil or fresh engine/hydraulic oil. Burnt oil has a high sulphur content and, most importantly, reduces lubrication qualities.

Dedicated chain oil has the required cling properties in order to keep it on the chain during use where most other oils would be flung of the chain instantly. When buying two-stroke oil, buy a quality brand and mix at the required ratio stated by the manufacturer.

6. Personal Protective Equipment (PPE)

Safety is paramount and should be considered at all times. All guards on the saw should be intact and the correct personal protective equipment (PPE) should be worn at all times when the chainsaw is in operation, regardless of how big or small the task is.

This includes a safety helmet with faceguard, ear defenders, safety steel-toe boots, gloves and chainsaw trousers.

A branded set including a helmet with face shield and ear defenders, trousers and gloves will cost between €170 and €200. This should be seen as an investment in your safety.

PPE is a must. A kit containing protective trousers, gloves and a helmet with face guard can be bought for less than €200.

On the majority of Irish farms, a chainsaw is very much a sporadic tool, called upon in the aftermath of a storm or when a tree need to be delimbed or logged.

Chainsaws tend to be one of those tools that are put away after use and not thought about until needed once again and therefore can go in need of a service for long periods of time.

However, it is good practice to service a chainsaw once a year, or more frequently, depending on the level of usage. Here, we look at the key areas and components to consider before making a cut.

1. Spark plug

It is advised to replace the spark plug at every service. A worn-out spark plug will leave the chainsaw hard to start or fail to start in the worst scenario.

A spark plug will only cost around €5. When removing the old spark plug check its condition as this can indicate how the engine is running.

If the porcelain insulator is cracked, an electrode may be damaged or burnt. A grey colour can indicate that the piston has suffered damage.

The grey colour is caused as result of the aluminium burning within the cylinder.

Speak with your local repair specialist, if this is the case.

2. Air and fuel filter

Every service should see both the fuel and air filters replaced. For most, a fuel filter typically costs only €5 or €6. The air filter and vents should be cleaned/blown out with compressed air between services and depending on cutting conditions.

A blocked air intake could cause the saw to overheat, while a blocked air filter will smother the engine and cause it to run inefficiently or stall. Air filters will generally cost no more than €15.

It is advised to empty the fuel tank of petrol before long periods of storage. It is not uncommon for constituents of the two-stroke fuel mix ingredients to evaporate and leave behind a jelly-like residue.

If this occurs, then it may clog up the carburettor. In most cases, carburettor cleaner will resolve the issue; if not, the carburettor will need replaced.

Costing only a few Euros, the fuel filter too should be replaced at each service.

3. Sharpening a dull chain

Chain sharpening is a skill that takes considerable practice for a clean, straight cut, as replication is key between each cutter. However, it’s something the majority of people can do to improve their cuts.

When you find yourself leaning on the chainsaw to make it cut, it’s a sure indication that the chain needs sharpened.

Not only does this take longer, it uses more fuel and, over a prolonged period, will lead to chain damage and premature bar and sprocket wear. A chain can instantly lose its edge if contact with clay or a stone is made.

Regardless of the sharpening method, each cutting tooth on the chain will have a diagonal line, usually called a witness mark. This indicates the sharpening angle and marks the end of the life of the chain when filed to this point.

Chains can be sharpened manually using a file or using an electric sharpener. An electric sharpener requires the chain to be removed from the guide bar.

A simple round file is the most basic option. However, there is a two-in-one tool available that sharpens both the cutters and depth gauge (rakers) simultaneously.

Selecting a round file to sharpen the chain is not a one-size-fits-all approach. So, identify the chain size. Once the right size file has been selected, it or the two-in-one tool should be held level and at the correct angle. It then needs to be drawn from the inside of the cutter to the outside of the cutter.

Sharpen all the cutters on one side of the chain first, giving each the same number of passes (key for a straight cut), then file the cutters on the opposite side.

It should be relatively easy to see where you started, as the sharpened cutters tend to be shiny with traces of filings. As a chain is sharpened, its depth gauges need to be lowered.

The two-in-one tool does this automatically, but those using a standard round file will need to follow with a flat file and lower the rakers separately. Too low and the saw will bite too much into the timber, causing it to jump; if too high, the chainsaw will be unable to cut. If in doubt, it may be best to have the chain professionally sharpened.

A two-in-one sharpening tool is a worthwhile investment.

4. Guide bar and chain brake

The guide bar is in fact a wearing part and a component often overlooked. The track on which the chain runs needs to be kept clean for proper lubrication to take place. There is a bearing and sprocket at the top of each guide bar on which the chain rotates.

This bearing should receive grease via the small hole on the side of the bar regularly. If the chain channel has widened enough that the chain has become loose, then the bar will need to be replaced or turned upside-down. The top side will naturally wear more, so when wear just about becomes visible, turn it upside down to get that bit extra use out of it before replacement.

Chain tension is also important: too tight and it will not move freely on the guide bar, too loose and it has the possibility of coming off the bar.

It should be tightened to the point that it is just resting against the bottom side of the guide bar. Run the saw for a few minutes and recheck the tension and adjust if necessary.

The chain brake is a critical safety feature on any chainsaw and needs to be functional. It is simply a steel band around the saw’s clutch drum. Once activated, the band tightens on the clutch drum and stops the chain immediately. It is good practice to apply the brake every time the saw is left down, during sharpening or not in use. A saw with no chain brake should not be used.

5. Chain lubrication

A well-serviced saw should consume one tank of chain oil to one tank of two-stroke fuel used. It is important that dedicated chain oil is used and not burnt oil or fresh engine/hydraulic oil. Burnt oil has a high sulphur content and, most importantly, reduces lubrication qualities.

Dedicated chain oil has the required cling properties in order to keep it on the chain during use where most other oils would be flung of the chain instantly. When buying two-stroke oil, buy a quality brand and mix at the required ratio stated by the manufacturer.

6. Personal Protective Equipment (PPE)

Safety is paramount and should be considered at all times. All guards on the saw should be intact and the correct personal protective equipment (PPE) should be worn at all times when the chainsaw is in operation, regardless of how big or small the task is.

This includes a safety helmet with faceguard, ear defenders, safety steel-toe boots, gloves and chainsaw trousers.

A branded set including a helmet with face shield and ear defenders, trousers and gloves will cost between €170 and €200. This should be seen as an investment in your safety.

PPE is a must. A kit containing protective trousers, gloves and a helmet with face guard can be bought for less than €200.

SHARING OPTIONS