Wood is the oldest building material in the world, but it fell out of favour for centuries, especially in countries like Ireland which has a masonry rather than a wood culture. However, timber is enjoying a renaissance in countries with strong wood cultures where architects and engineers understand its versatility and variability.

Variability in wood is challenging for those who are used to working with steel and concrete, but now wood can be used with similar accuracy, providing it is engineered. Engineered wood, especially cross laminated timber (CLT) provides the strength to construct buildings over 80m tall and there are plans to go much higher. The species used are softwoods such as Douglas fir in North America and Norway spruce in Europe.

NUI Galway has been experimenting with Sitka spruce to see if it is suitable for CLT. In a recent interview with the Irish Farmers Journal, Dr Conan O’Ceallaigh, adjunct lecturer and post-doctoral researcher in NUIG, discussed CLT and the work of the Timber Engineering Research Group (TERG) at the university, which is funded by the Department of Agriculture, Food and the Marine.

Can you explain what CLT is?

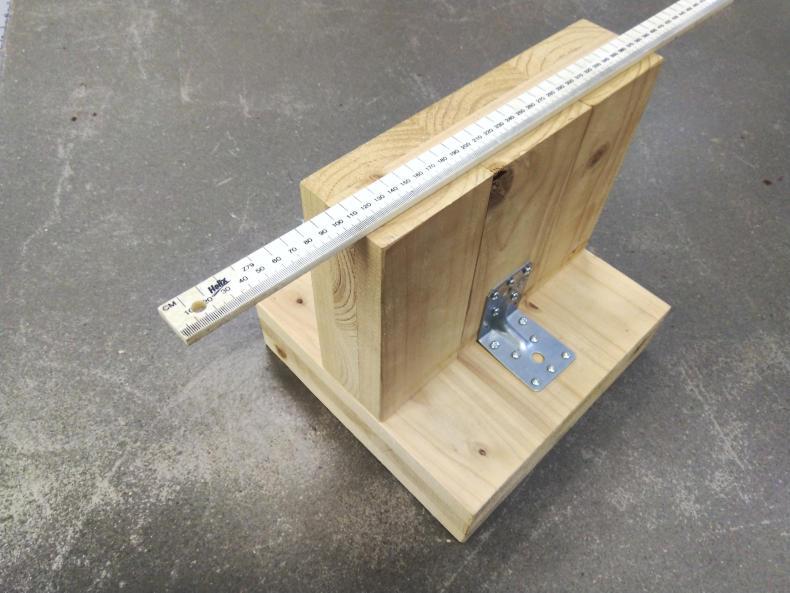

CLT is a multi-layer engineered wood product made of at least three orthogonally bonded layers of timber. In order to increase rigidity and stability, each layer of boards is placed cross-wise to form a solid rectangular-shaped timber panel. This engineered wood product may be sized, cut and shaped accordingly off-site into ready-to-use building components.

So in addition to its environmental benefits, it is a fast building system.

Yes, it is easily and quickly assembled to form complete frameworks. This maximises efficiency on all levels, improving construction and project delivery time and reducing labour costs.

Is Sitka spruce suitable for new higher value products, such as CLT?

The outcomes of the research projects completed by TERG have confirmed that there is potential to use Irish Sitka spruce for CLT manufacture and this presents new opportunities for the Irish timber industry. A series of tests were performed to characterise the structural behaviour of three and five layer CLT panels manufactured from C16 grade timber grown in Ireland. The findings suggest that C16 timber is suitable for the manufacture of CLT products.

What are the benefits of engineered Sitka in adding value to the species and displacing fossil based product?

An important objective of our research is to provide evidence and expertise related to the performance of wood-based products and building systems, and demonstrate the benefits of using timber products as a carbon store in the fight against climate change. When used as a structural element of a building, in addition to cladding and fittings, carbon sequestered in such wood-based products can significantly lower a buildings embodied carbon profile. In this context, the use of local materials is important to minimise transportation emissions and support local employment. This practice could be essential if we are to transition into a net-zero carbon economy and achieve targets set out in the Paris Climate Agreement.

What has been achieved in CLT construction in Europe and America?

There is a move towards green and sustainable construction across Europe and this has promoted the use of engineered wood products (EWPs) in structural applications. For example, the borough of Hackney in London introduced a wood first policy in 2012 to stimulate timber construction as a climate change mitigation strategy. Today there are over 25 large timber structures in the borough, with projects such as schools, community offices and residential building up to 10 storeys tall. Dalston Lane in Hackney is a 33.8m tall, constructed from CLT. An estimated 2,400t net CO2 is saved in this structure, compared to the equivalent concrete frame. This is comparable to taking 520 cars off the road for a year.

The world’s tallest timber structure is the 85m Mjøstårnet building in Norway, an 18 storey mixed-use building constructed with floors and elevator shafts made entirely of CLT and glulam columns.

What is the next stage for CLT in Ireland?

The development of CLT will require significant investment in manufacturing infrastructure by Irish timber processors and manufacturers. Architects, engineers, designers, timber processors and forest owners will be interested in our seminar on sustainable wood construction scheduled for the National Botanic Gardens Conference Centre, Glasnevin, Dublin on 31 October which NUIG is organising with the Wood Marketing Federation and the Society of Irish Foresters. Contact the Society of Irish Foresters (info@soif.ie) for further information and booking.

SHARING OPTIONS