The Targeted Agricultural Modernisation Scheme (TAMS) has offered farmers a great opportunity to make the move to low emission slurry spreading (LESS) technology. In terms of slurry application methods, the writing has been on the wall for some time now, and policy is only going in one direction.

The Government’s recently unveiled new Nitrates Action Programme included tighter restrictions on spreading dates, banning of soiled water spreading in December, new rules for slurry spreading in October and the introduction of mandatory LESS, even on lowly stocked farms. This group will soon join the 12,500 farmers who were required to make the move to the use of such technology last year.

As a result, many farmers are availing of the grant aid support through TAMS to make the move to LESS. Research has shown the many benefits of this technology, and with the current price of artificial fertiliser, the additional benefits of using LESS equipment have never been as important.

However, farmers need to be aware that the forward speed when using the typical LESS systems, such as a dribble bar or trailing shoe, needs to be significantly increased compared to using a traditional splash plate to achieve the same application rate.

Trial

If you make the move to a LESS system for the first time, one of the first things you will notice is how quick you will empty the tanker in comparison to when using the splash plate.

Applying slurry on the Irish Farmers Journal’s demonstration farm in Tullamore last year, we used a 2,750-gallon tanker which was using an 11,000-litre pump and was fitted with a nine-metre dribble bar. When using the splash plate, the average working width of the application on to the surface was measured at approximately 13.5m, while the time to empty was about 6 minutes and 25 seconds.

Next up, we trialled applying slurry through the dribble bar, using the same tanker. This dribble bar had a nine-metre working width, and distributed the slurry through 40 outlets which were fed by a Vogelsang distributor. It took about 4 minutes and 25 seconds to empty.

Why did it empty so quickly?

Slurry being applied through the splash plate had to be fed out through the one narrow gap, measured at 55mm. When we moved to the LESS system, the opening feeding the macerator is increased two-fold and in some cases this goes up three-fold, in addition to far more outlets. The working width is significantly reduced, while the flow of slurry to feed the large number of outlets is increased, so naturally the tanker will empty far quicker.

The point to note is that when using LESS systems, the tractor’s forward speed needs to be significantly increased to match the splash plate’s application rate. A factor often overlooked by many; forward speed is key to an even application at the correct rate.

Target rate

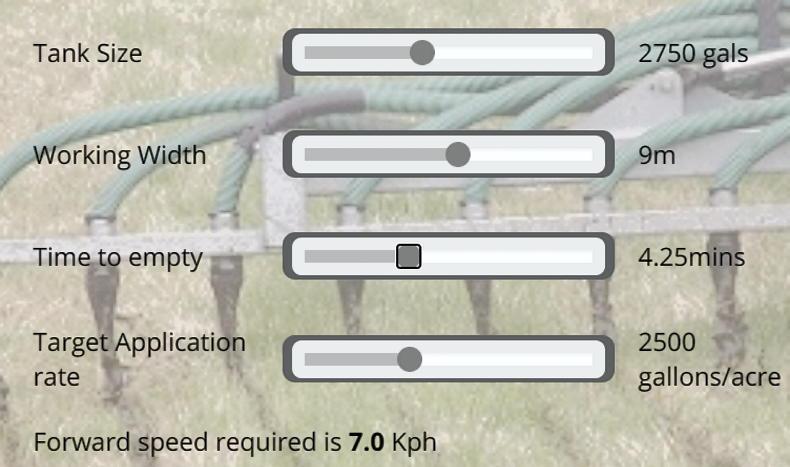

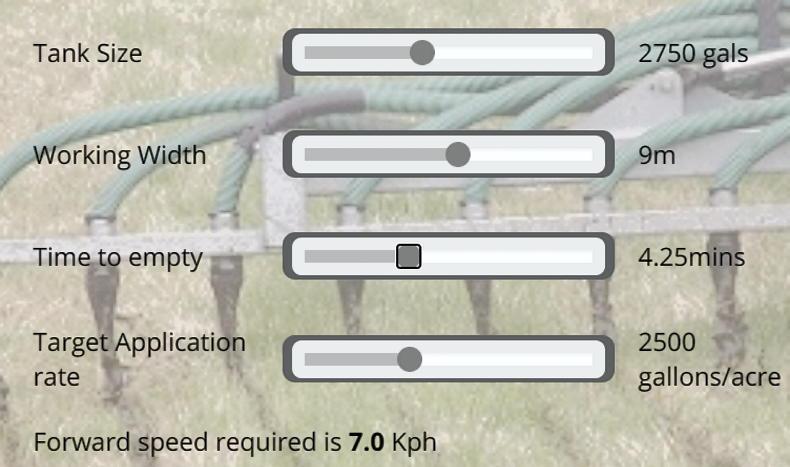

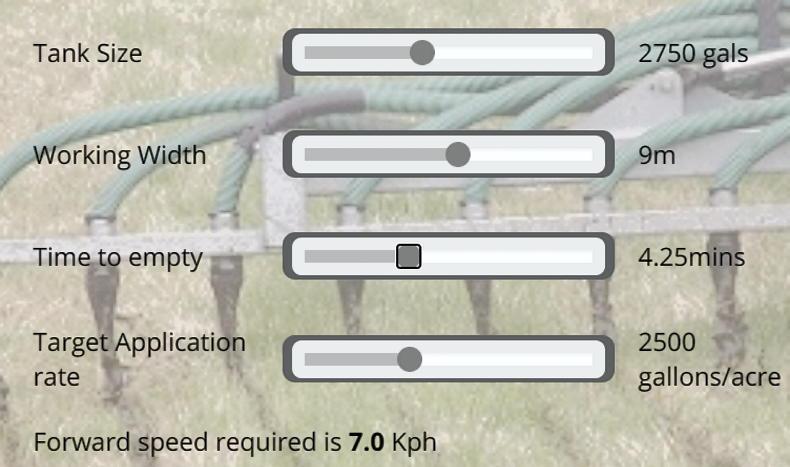

To find out the difference in forward speed required to apply our then target rate of 2,500 gallons per acre, we used the Teagasc slurry calibration calculator.

We found this calculator to be one of the simplest available. It requires four pieces of information in order to determine the correct forward speed required to apply the desired rate. The details required include the size of the tanker (gallons), the working width of the application system (metres), the time taken to empty the tanker and the targeted application rate. The calculator will then indicate the required forward speed in km/h to achieve the desired rate.

By entering all the above information from our trial, the calculator advised operating at a forward speed of 3.2km/h when using the splash plate, and 7km/h when applying slurry with the dribble bar.

Although a 2,750-gallon tanker is larger than what most farmers are running, so too is the 9m dribble bar. The most common working width LESS system being sold in Ireland is 7.5m. Despite this, the concept of the increased forward speed remains the same. When moving to a new application method, it is imperative to ensure you are applying slurry evenly and at the correct rate.

When using the splash plate in our trial, the calculator advised operating at a forward speed of 3.2km/h.

When we changed to the dribble bar, the advised forward speed over doubled to 7km/h.

Does your tractor have enough horsepower?

We have learnt of farmers running into problems building up enough forward speed with the tractor to achieve this desired application rate. This is especially the case when working with more difficult conditions around the shoulders of the year.

In a similar situation, those following the grazing rotation and applying slurry to paddocks at lower application rates, such as at 1,500 gallons per acre, need to up forward speed even more. In fact, based on the above criteria, the calibration calculator would advise that forward speed edges towards 12km/h.

In typical summer conditions, most tractors will comfortably achieve this forward speed, but not at the 300-400 PTO rpm (1,100 rpm give or take engine speed) which most pumps run at.

Increased hydraulic requirement

LESS systems also place an increased hydraulic requirement on the operating tractor. This tends to be a lesser issue than the hp requirement, but one worth noting for those running smaller tractors. Today, many farmers are opting for 2,300- and 2,600-gallon tankers equipped with the typical 7.5m wide LESS systems.

Taking such an entry level dribble bar as the benchmark, the macerator has a hydraulic requirement in the region of 55-65l/min. If the tractor uses closed-centre or load-sensing hydraulics, the oil flow will prioritise the tractor’s safety features such as the steering and the brakes. The steering alone would sap around a further flow of 20l/min, bringing the requirement up to 85l/min.

Depending on the tractor used and its spec, its hydraulic setup and capacity will vary. Most will be fine, but it is worth double-checking before investing. Tractors which use open centre hydraulics may seem to have a lower hydraulic capacity, but are fitted with a secondary pump (20-30l/min) to cater for the steering. Tractors that use closed-centre or load-sensing hydraulics do not have this extra capacity.

A 100-110hp tractor with a limited hydraulic capacity trying to meet the targeted forward speed for the desired application rate in challenging conditions at the shoulders of the year could quickly end up out of its depth. Manufacturers are recommending a minimum of 120-130hp tractor for a typical 2,300- or 2,600-gallon tanker with a dribble bar or trailing shoe system.

Considerations before investing

Before making the investment in expensive LESS application systems, farmers should ask themselves or their local machinery dealer if their tractor is fit for purpose. They should also consider whether or not the system upgrade is a cost-effective investment for their holding. At a basic level, to retrofit an entry-level dribble bar, you will have to part with give or take €12,000 plus VAT.

Moving to a LESS system will involve learning new operational skills. The last thing you want is to end up being forced to further invest in a larger tractor, leading to more capital outlay and additional fuel consumption, potentially tipping the scales and outweighing the previously prescribed benefits.

In summary

When moving to a LESS method, ensure you are applying the slurry evenly and at the correct rate.LESS systems (particularly the common 7.5m attachments) require an increased forward speed to maintain the same application rate as a splash plate.Teagasc has an online calibration calculator which advises users of the correct forward speed to achieve their desired application rate.The calculator requires the tank size, the working width, the time to empty and the desired application rate, before providing you with the forward speed needed. LESS systems also require an increased hydraulic capacity.Before investing in LESS, do you know if your tractor is fit for purpose?

The Targeted Agricultural Modernisation Scheme (TAMS) has offered farmers a great opportunity to make the move to low emission slurry spreading (LESS) technology. In terms of slurry application methods, the writing has been on the wall for some time now, and policy is only going in one direction.

The Government’s recently unveiled new Nitrates Action Programme included tighter restrictions on spreading dates, banning of soiled water spreading in December, new rules for slurry spreading in October and the introduction of mandatory LESS, even on lowly stocked farms. This group will soon join the 12,500 farmers who were required to make the move to the use of such technology last year.

As a result, many farmers are availing of the grant aid support through TAMS to make the move to LESS. Research has shown the many benefits of this technology, and with the current price of artificial fertiliser, the additional benefits of using LESS equipment have never been as important.

However, farmers need to be aware that the forward speed when using the typical LESS systems, such as a dribble bar or trailing shoe, needs to be significantly increased compared to using a traditional splash plate to achieve the same application rate.

Trial

If you make the move to a LESS system for the first time, one of the first things you will notice is how quick you will empty the tanker in comparison to when using the splash plate.

Applying slurry on the Irish Farmers Journal’s demonstration farm in Tullamore last year, we used a 2,750-gallon tanker which was using an 11,000-litre pump and was fitted with a nine-metre dribble bar. When using the splash plate, the average working width of the application on to the surface was measured at approximately 13.5m, while the time to empty was about 6 minutes and 25 seconds.

Next up, we trialled applying slurry through the dribble bar, using the same tanker. This dribble bar had a nine-metre working width, and distributed the slurry through 40 outlets which were fed by a Vogelsang distributor. It took about 4 minutes and 25 seconds to empty.

Why did it empty so quickly?

Slurry being applied through the splash plate had to be fed out through the one narrow gap, measured at 55mm. When we moved to the LESS system, the opening feeding the macerator is increased two-fold and in some cases this goes up three-fold, in addition to far more outlets. The working width is significantly reduced, while the flow of slurry to feed the large number of outlets is increased, so naturally the tanker will empty far quicker.

The point to note is that when using LESS systems, the tractor’s forward speed needs to be significantly increased to match the splash plate’s application rate. A factor often overlooked by many; forward speed is key to an even application at the correct rate.

Target rate

To find out the difference in forward speed required to apply our then target rate of 2,500 gallons per acre, we used the Teagasc slurry calibration calculator.

We found this calculator to be one of the simplest available. It requires four pieces of information in order to determine the correct forward speed required to apply the desired rate. The details required include the size of the tanker (gallons), the working width of the application system (metres), the time taken to empty the tanker and the targeted application rate. The calculator will then indicate the required forward speed in km/h to achieve the desired rate.

By entering all the above information from our trial, the calculator advised operating at a forward speed of 3.2km/h when using the splash plate, and 7km/h when applying slurry with the dribble bar.

Although a 2,750-gallon tanker is larger than what most farmers are running, so too is the 9m dribble bar. The most common working width LESS system being sold in Ireland is 7.5m. Despite this, the concept of the increased forward speed remains the same. When moving to a new application method, it is imperative to ensure you are applying slurry evenly and at the correct rate.

When using the splash plate in our trial, the calculator advised operating at a forward speed of 3.2km/h.

When we changed to the dribble bar, the advised forward speed over doubled to 7km/h.

Does your tractor have enough horsepower?

We have learnt of farmers running into problems building up enough forward speed with the tractor to achieve this desired application rate. This is especially the case when working with more difficult conditions around the shoulders of the year.

In a similar situation, those following the grazing rotation and applying slurry to paddocks at lower application rates, such as at 1,500 gallons per acre, need to up forward speed even more. In fact, based on the above criteria, the calibration calculator would advise that forward speed edges towards 12km/h.

In typical summer conditions, most tractors will comfortably achieve this forward speed, but not at the 300-400 PTO rpm (1,100 rpm give or take engine speed) which most pumps run at.

Increased hydraulic requirement

LESS systems also place an increased hydraulic requirement on the operating tractor. This tends to be a lesser issue than the hp requirement, but one worth noting for those running smaller tractors. Today, many farmers are opting for 2,300- and 2,600-gallon tankers equipped with the typical 7.5m wide LESS systems.

Taking such an entry level dribble bar as the benchmark, the macerator has a hydraulic requirement in the region of 55-65l/min. If the tractor uses closed-centre or load-sensing hydraulics, the oil flow will prioritise the tractor’s safety features such as the steering and the brakes. The steering alone would sap around a further flow of 20l/min, bringing the requirement up to 85l/min.

Depending on the tractor used and its spec, its hydraulic setup and capacity will vary. Most will be fine, but it is worth double-checking before investing. Tractors which use open centre hydraulics may seem to have a lower hydraulic capacity, but are fitted with a secondary pump (20-30l/min) to cater for the steering. Tractors that use closed-centre or load-sensing hydraulics do not have this extra capacity.

A 100-110hp tractor with a limited hydraulic capacity trying to meet the targeted forward speed for the desired application rate in challenging conditions at the shoulders of the year could quickly end up out of its depth. Manufacturers are recommending a minimum of 120-130hp tractor for a typical 2,300- or 2,600-gallon tanker with a dribble bar or trailing shoe system.

Considerations before investing

Before making the investment in expensive LESS application systems, farmers should ask themselves or their local machinery dealer if their tractor is fit for purpose. They should also consider whether or not the system upgrade is a cost-effective investment for their holding. At a basic level, to retrofit an entry-level dribble bar, you will have to part with give or take €12,000 plus VAT.

Moving to a LESS system will involve learning new operational skills. The last thing you want is to end up being forced to further invest in a larger tractor, leading to more capital outlay and additional fuel consumption, potentially tipping the scales and outweighing the previously prescribed benefits.

In summary

When moving to a LESS method, ensure you are applying the slurry evenly and at the correct rate.LESS systems (particularly the common 7.5m attachments) require an increased forward speed to maintain the same application rate as a splash plate.Teagasc has an online calibration calculator which advises users of the correct forward speed to achieve their desired application rate.The calculator requires the tank size, the working width, the time to empty and the desired application rate, before providing you with the forward speed needed. LESS systems also require an increased hydraulic capacity.Before investing in LESS, do you know if your tractor is fit for purpose?

SHARING OPTIONS