Based at Whitechurch, just north of Cork city, Hegarty Agri is run by three brothers – Pat, James and William. Growing a mix of winter and spring cereals, the family also grows maize on contract.

Always eager to improve, the Hegartys were looking at the Lemken Karat for a while and made the decision to purchase the machine for two reasons.

Firstly, it was predominately bought to reduce the amount of ploughing done on the farm. They felt it would be ideal after deep rooting crops like maize, beans or oats, to help speed up the cultivation process.

Secondly, the family operation was previously sowing cover crops using a Lemken Solitair 4m trailed disc drill.

Although the machine was doing a near-perfect job, it was causing excess wear on the drill, costing too much to establish the crop. The brothers felt that moving to a trailed Karat with a basic air seeder would provide a lower cost of crop establishment, while not compromising on the job at hand.

“The move to the Lemken 4m trailed Karat has worked out very well. We are in our second season with the machine and have probably put around 1,500 acres though it. Obviously, this is a very busy time of the year on tillage farms.

"Ideally around now, on ground that’s not being cover cropped and where we have straw cleared, we like to get into stubbles with the Karat. The idea here is to incorporate and mix chopped straw, stubble and roots into the soil to promote rapid rotting, while germinating volunteer weeds.

"Then before winter cultivations begin, we spray off the fields and get in again with the Karat for a deeper cultivation just ahead of sowing,” explained Pat.

The brothers felt that moving to a trailed Karat with a basic air seeder would provide a lower cost of cover crop establishment.

The design

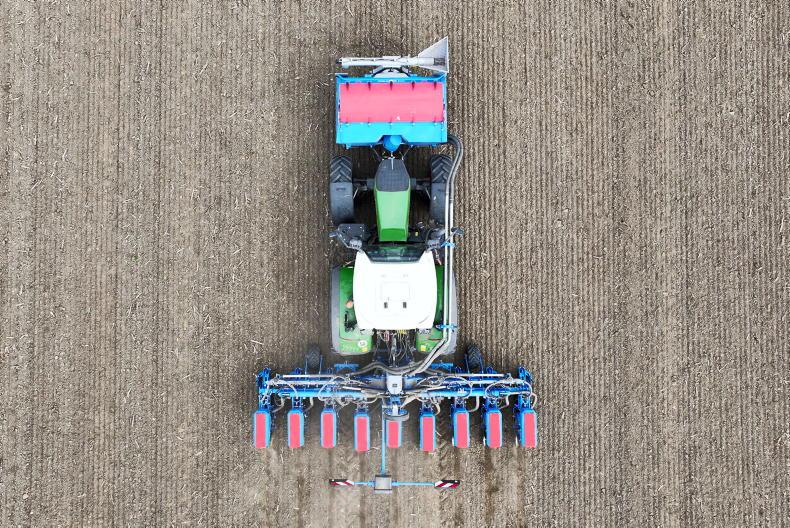

Two years ago, well-known German machinery manufacturer Lemken launched the Karat 10 three-beam cultivator, offering it in mounted and semi-mounted versions. The tines are arranged symmetrically around the tensile axis, in an attempt to make the machine low-draught and to avoid side draft. Lemken says this is particularly important when using the cultivator with track guidance systems, while ensuring intensive mixing.

The new design means that the wing shares for shallow cultivation have been widened. Alternatively, narrow shares can be used for deep cultivation. All shares are optionally available in carbide. The machine comes as standard with the quick-change system, which allows the shares to be changed quickly for working depths of up to 30cm. To change shares, the interchangeable share foot, which is secured by a linch pin, is removed and swapped for the desired replacement share. No tools are required.

The 4m trailed version features 31 legs.

“Although there are lots of various shares and sizes available, we typically only use two. One is a ducks foot type, which tends to work approximately one foot in width. The second is a more standard grubber type tip. Both are carbide and tungsten tipped. We find the Lemken wearing parts to be expensive, but you do get the acres out of them,” noted Pat.

It comes with centrally adjustable levelling tines, while specially shaped levelling discs are optionally available. Newly available are boundary discs, and tines can be folded up mechanically or hydraulically. The cultivator can be optionally fitted with a hydraulically adjustable leading disc section for incorporating large amounts of organic matter into the soil. The discs, with a diameter of 520mm, are individually suspended on leaf springs. The trailed version features a line distance of 31cm, a beam spacing of 100/100cm and an underframe clearance of 80cm. Thus, the 4m trailed version features 31 legs.

The new Karat 10 cultivator is available in mounted and semi-mounted versions, with working widths between three and seven metres.

The new Karat 10 cultivator is available in mounted and semi-mounted versions, with working widths between three and seven metres. A traction booster and the ContourTrack system for an even working depth in hilly terrain are available for the semi-mounted models, while it can be fitted with a range of rollers. A following harrow for removing soil from roots can be optionally mounted.

“The ContourTrack system and the hydraulic traction booster are a great job. The design incorporates a pivot point in the frame behind the working section with another hydraulic ram, which maintains the pre-set working depth, regardless of whether you work the machine into hills or hollows. A few years ago, we did a demo of the Karat – the machine had a double packer roller, and it was a serious job. However, when ordering the machine, we opted for a single packer roller. We found that the double packer roller leaves a far superior finish, but that if you got a shower of rain you would have to park up, or else the machine would block. We went for the single packer roller just to keep things simple, which also allows us to work on to finish a job, even if conditions begin to get tricky,” explained Pat.

"This spring, we cultivated oat stubble on one pass, ripping it eight to ten inches deep".

Verdict

“We are extremely happy with the Karat – clay and straw flows through the machine at its ease. The speed at which you can cover ground, while doing a proper uniform job, is very impressive. When sowing cover crops, we operate at 12-15km/h at a shallow depth and can easily cover up to 10ac/hr. We find that the Karat is extremely good at penetrating soil and it has a serious ability to maintain a pre-defined working depth at all times.

“The Karat has greatly sped up our sowing operations. For example, this spring, we cultivated oat stubble on one pass, ripping it eight to 10 inches deep. We then followed this with one run of our 6m trailed Solitair disc drill, while sowing on the same pass. We typically run the 4m trailed Karat on a John Deere 6250R, which is paired very well with the cultivator. The only thing we have against it is that we didn’t go for a 5m machine when we bought it,” explained Pat.

Based at Whitechurch, just north of Cork city, Hegarty Agri is run by three brothers – Pat, James and William. Growing a mix of winter and spring cereals, the family also grows maize on contract.

Always eager to improve, the Hegartys were looking at the Lemken Karat for a while and made the decision to purchase the machine for two reasons.

Firstly, it was predominately bought to reduce the amount of ploughing done on the farm. They felt it would be ideal after deep rooting crops like maize, beans or oats, to help speed up the cultivation process.

Secondly, the family operation was previously sowing cover crops using a Lemken Solitair 4m trailed disc drill.

Although the machine was doing a near-perfect job, it was causing excess wear on the drill, costing too much to establish the crop. The brothers felt that moving to a trailed Karat with a basic air seeder would provide a lower cost of crop establishment, while not compromising on the job at hand.

“The move to the Lemken 4m trailed Karat has worked out very well. We are in our second season with the machine and have probably put around 1,500 acres though it. Obviously, this is a very busy time of the year on tillage farms.

"Ideally around now, on ground that’s not being cover cropped and where we have straw cleared, we like to get into stubbles with the Karat. The idea here is to incorporate and mix chopped straw, stubble and roots into the soil to promote rapid rotting, while germinating volunteer weeds.

"Then before winter cultivations begin, we spray off the fields and get in again with the Karat for a deeper cultivation just ahead of sowing,” explained Pat.

The brothers felt that moving to a trailed Karat with a basic air seeder would provide a lower cost of cover crop establishment.

The design

Two years ago, well-known German machinery manufacturer Lemken launched the Karat 10 three-beam cultivator, offering it in mounted and semi-mounted versions. The tines are arranged symmetrically around the tensile axis, in an attempt to make the machine low-draught and to avoid side draft. Lemken says this is particularly important when using the cultivator with track guidance systems, while ensuring intensive mixing.

The new design means that the wing shares for shallow cultivation have been widened. Alternatively, narrow shares can be used for deep cultivation. All shares are optionally available in carbide. The machine comes as standard with the quick-change system, which allows the shares to be changed quickly for working depths of up to 30cm. To change shares, the interchangeable share foot, which is secured by a linch pin, is removed and swapped for the desired replacement share. No tools are required.

The 4m trailed version features 31 legs.

“Although there are lots of various shares and sizes available, we typically only use two. One is a ducks foot type, which tends to work approximately one foot in width. The second is a more standard grubber type tip. Both are carbide and tungsten tipped. We find the Lemken wearing parts to be expensive, but you do get the acres out of them,” noted Pat.

It comes with centrally adjustable levelling tines, while specially shaped levelling discs are optionally available. Newly available are boundary discs, and tines can be folded up mechanically or hydraulically. The cultivator can be optionally fitted with a hydraulically adjustable leading disc section for incorporating large amounts of organic matter into the soil. The discs, with a diameter of 520mm, are individually suspended on leaf springs. The trailed version features a line distance of 31cm, a beam spacing of 100/100cm and an underframe clearance of 80cm. Thus, the 4m trailed version features 31 legs.

The new Karat 10 cultivator is available in mounted and semi-mounted versions, with working widths between three and seven metres.

The new Karat 10 cultivator is available in mounted and semi-mounted versions, with working widths between three and seven metres. A traction booster and the ContourTrack system for an even working depth in hilly terrain are available for the semi-mounted models, while it can be fitted with a range of rollers. A following harrow for removing soil from roots can be optionally mounted.

“The ContourTrack system and the hydraulic traction booster are a great job. The design incorporates a pivot point in the frame behind the working section with another hydraulic ram, which maintains the pre-set working depth, regardless of whether you work the machine into hills or hollows. A few years ago, we did a demo of the Karat – the machine had a double packer roller, and it was a serious job. However, when ordering the machine, we opted for a single packer roller. We found that the double packer roller leaves a far superior finish, but that if you got a shower of rain you would have to park up, or else the machine would block. We went for the single packer roller just to keep things simple, which also allows us to work on to finish a job, even if conditions begin to get tricky,” explained Pat.

"This spring, we cultivated oat stubble on one pass, ripping it eight to ten inches deep".

Verdict

“We are extremely happy with the Karat – clay and straw flows through the machine at its ease. The speed at which you can cover ground, while doing a proper uniform job, is very impressive. When sowing cover crops, we operate at 12-15km/h at a shallow depth and can easily cover up to 10ac/hr. We find that the Karat is extremely good at penetrating soil and it has a serious ability to maintain a pre-defined working depth at all times.

“The Karat has greatly sped up our sowing operations. For example, this spring, we cultivated oat stubble on one pass, ripping it eight to 10 inches deep. We then followed this with one run of our 6m trailed Solitair disc drill, while sowing on the same pass. We typically run the 4m trailed Karat on a John Deere 6250R, which is paired very well with the cultivator. The only thing we have against it is that we didn’t go for a 5m machine when we bought it,” explained Pat.

SHARING OPTIONS