Over the years, the European Commission has repeatedly recognised Ireland as having the highest potential to produce biomethane per capita in Europe, mainly due to our large agricultural industry and ability to grow biomass.

This recognition seems to have resonated as, despite no support scheme being in place, ongoing public opposition to the technology and likely long waiting times for a gas grid connection, Ireland is proving to be an area of keen interest to anaerobic digestion (AD) developers, both domestic and international.

The latest international developer to set its sights on Ireland is London-based CycleØ. Earlier this month, it opened its first Irish branch and appointed former Mullinahone Co-op manager James Manley as its Irish manager. CycleØ, however, is unique in that it is concentrating on the small- to medium-scale AD plant market.

The Irish Farmers Journal recently sat down with CycleØ CEO Laurence Molke to learn more about the business, its technology and its plans for Ireland.

About

CycleØ describes itself as an end-to-end biomethane developer which builds, owns and operates biomethane plants. It currently owns 18 biomethane projects in different stages of development across Europe and Latin America.

The upgraders are assembled and tested in the CycleØ factory in Spain.

Ara Partners, a private equity firm with its European headquarters located in Dublin, established CycleØ after acquiring FNX LNG, a Spanish business that produces containerised biogas upgraders and liquefaction plants for small- and medium-scale AD plants.

Molke stated that CycleØ’s unique strength lies in its ability to develop feasible small- and medium-scale AD plants using containerised or “skid-mounted” upgrading equipment.

This innovation has the potential to unlock a variety of “stranded feedstocks” that are difficult to access, such as food waste from agri-food companies or slurry from Irish farms, he says.

CycleØ identified the gap in the market for small- to medium-scale plants in Ireland and is now actively looking for farming partners.

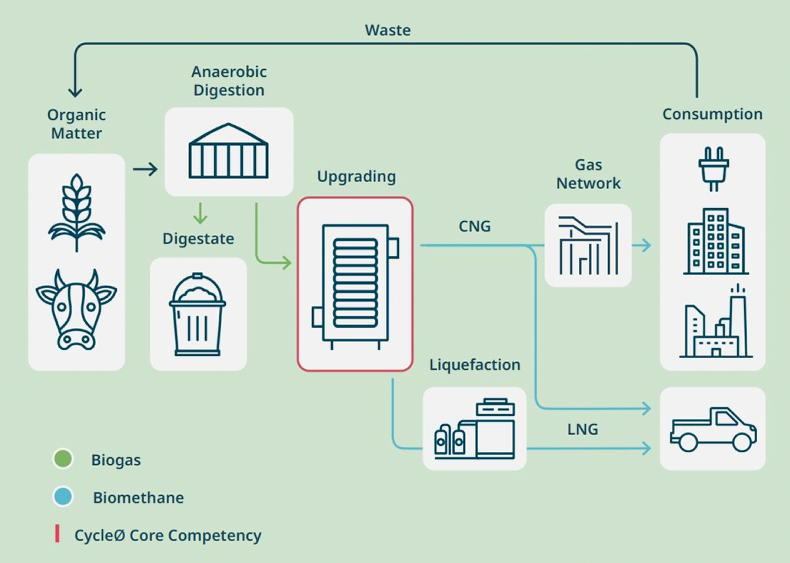

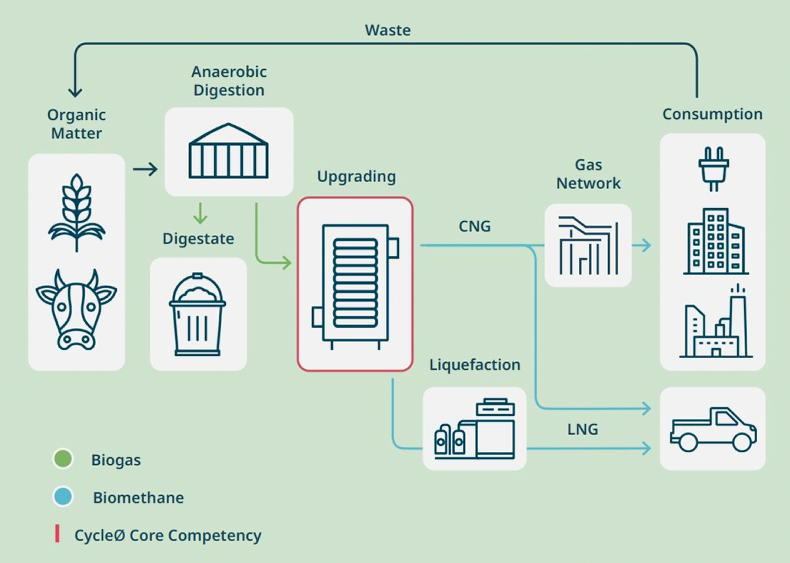

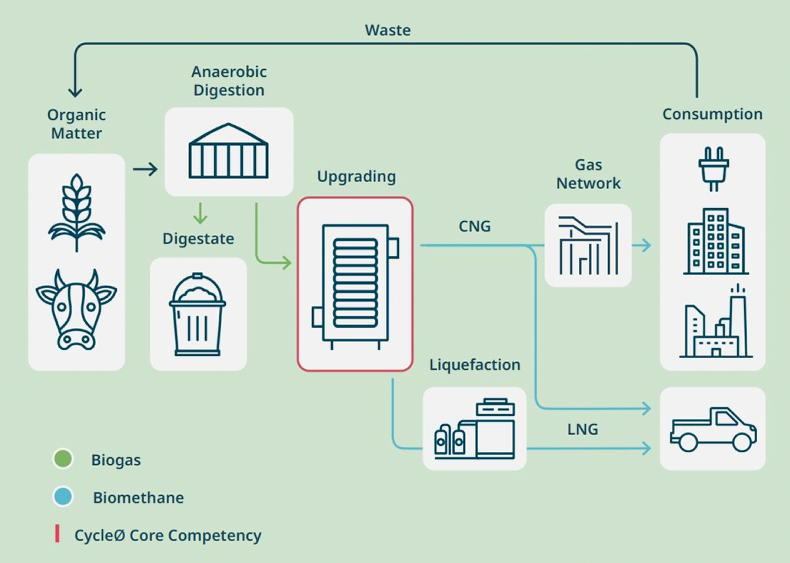

The biomethane upgrading process.

Small-scale plants

The company’s plan is to establish AD plants throughout Ireland that produce biomethane gas, which can be injected into the gas network for use in the heating sector or as vehicle fuel.

The gas can be transported from the plants via road to an injection point or the plant can be directly connected to the gas grid. CycleØ categorises a small-scale AD plant as comparable in size to a standard plant in Northern Ireland (below 500kW in electrical output).

A plant of this scale would need to be supplied with around 500 acres worth of feedstock along with approximately 5,000t of slurry annually. Producing biomethane from small-scale AD plants has historically been challenging due to the high investment and operational costs of biogas upgrading equipment.

However, Molke states that CycleØ’s skid-mounted upgrading plants enable economies of scale, leading to reduced investment costs compared to traditional projects, making it possible for them to construct smaller AD plants.

With the backing of Ara, the company is providing 100% of the funding to develop and own AD plants across Ireland and develop a commercial arrangement with farmers for feedstock supply. It views Ireland as being a market with a lot of potential but it is also very challenging, explains Molke.

CycleØ's skid-mounted upgrading plants allow reduced investment costs compared to traditional projects.

“If there was a good economic return or a good backdrop, historically we would have already seen more biomethane plants,” he says.

Nonetheless, Molke indicated that the company is open to considering other models where farmers can provide capital or share some of the financial risks.

However, he made it clear that CycleØ has no intention of providing capital to farmers to develop their own plants, but instead is seeking partners.

Typically, CycleØ works with local contractors to complete the civil work, such as tank construction and equipment supply for the plant, while supplying its own biogas upgrading systems.

Any small-scale AD plant must have full planning permission and the necessary licences in place.

The company believes that, in the absence of a support scheme, investing in the Irish AD sector could prove to be very high-risk for other lenders such as banks.

CycleØ CEO Laurence Molke.

Molke acknowledges that CycleØ will face competition from other biomethane producers across Europe, who benefit from various financial schemes, so he would like to see a level playing field in Ireland where the underlying price for biomethane is equal. This means introducing a government support scheme.

Despite this, the company is willing to commit the capital and enter the market as it currently stands.

“We know that if you have a market with a good source of feedstock and is encouraging grid injection, then the returns will come in time and will make sense,” he says.

CycleØ wants to work with one or more existing developers who are already at various stages in the planning process but the company is also prepared to work with new partners.

Agribusinesses or a dairy farmer with 400 cows-plus who can access extra grass silage is a candidate for them, he says.

Molke says that CycleØ is currently engaged in several discussions with Irish parties and aims to start construction of at least one plant by the end of the year.

“There is nothing like having a plant in place for people to come and see and understand how it works. We’ve experienced the same thing in other markets,” he says.

Over the years, the European Commission has repeatedly recognised Ireland as having the highest potential to produce biomethane per capita in Europe, mainly due to our large agricultural industry and ability to grow biomass.

This recognition seems to have resonated as, despite no support scheme being in place, ongoing public opposition to the technology and likely long waiting times for a gas grid connection, Ireland is proving to be an area of keen interest to anaerobic digestion (AD) developers, both domestic and international.

The latest international developer to set its sights on Ireland is London-based CycleØ. Earlier this month, it opened its first Irish branch and appointed former Mullinahone Co-op manager James Manley as its Irish manager. CycleØ, however, is unique in that it is concentrating on the small- to medium-scale AD plant market.

The Irish Farmers Journal recently sat down with CycleØ CEO Laurence Molke to learn more about the business, its technology and its plans for Ireland.

About

CycleØ describes itself as an end-to-end biomethane developer which builds, owns and operates biomethane plants. It currently owns 18 biomethane projects in different stages of development across Europe and Latin America.

The upgraders are assembled and tested in the CycleØ factory in Spain.

Ara Partners, a private equity firm with its European headquarters located in Dublin, established CycleØ after acquiring FNX LNG, a Spanish business that produces containerised biogas upgraders and liquefaction plants for small- and medium-scale AD plants.

Molke stated that CycleØ’s unique strength lies in its ability to develop feasible small- and medium-scale AD plants using containerised or “skid-mounted” upgrading equipment.

This innovation has the potential to unlock a variety of “stranded feedstocks” that are difficult to access, such as food waste from agri-food companies or slurry from Irish farms, he says.

CycleØ identified the gap in the market for small- to medium-scale plants in Ireland and is now actively looking for farming partners.

The biomethane upgrading process.

Small-scale plants

The company’s plan is to establish AD plants throughout Ireland that produce biomethane gas, which can be injected into the gas network for use in the heating sector or as vehicle fuel.

The gas can be transported from the plants via road to an injection point or the plant can be directly connected to the gas grid. CycleØ categorises a small-scale AD plant as comparable in size to a standard plant in Northern Ireland (below 500kW in electrical output).

A plant of this scale would need to be supplied with around 500 acres worth of feedstock along with approximately 5,000t of slurry annually. Producing biomethane from small-scale AD plants has historically been challenging due to the high investment and operational costs of biogas upgrading equipment.

However, Molke states that CycleØ’s skid-mounted upgrading plants enable economies of scale, leading to reduced investment costs compared to traditional projects, making it possible for them to construct smaller AD plants.

With the backing of Ara, the company is providing 100% of the funding to develop and own AD plants across Ireland and develop a commercial arrangement with farmers for feedstock supply. It views Ireland as being a market with a lot of potential but it is also very challenging, explains Molke.

CycleØ's skid-mounted upgrading plants allow reduced investment costs compared to traditional projects.

“If there was a good economic return or a good backdrop, historically we would have already seen more biomethane plants,” he says.

Nonetheless, Molke indicated that the company is open to considering other models where farmers can provide capital or share some of the financial risks.

However, he made it clear that CycleØ has no intention of providing capital to farmers to develop their own plants, but instead is seeking partners.

Typically, CycleØ works with local contractors to complete the civil work, such as tank construction and equipment supply for the plant, while supplying its own biogas upgrading systems.

Any small-scale AD plant must have full planning permission and the necessary licences in place.

The company believes that, in the absence of a support scheme, investing in the Irish AD sector could prove to be very high-risk for other lenders such as banks.

CycleØ CEO Laurence Molke.

Molke acknowledges that CycleØ will face competition from other biomethane producers across Europe, who benefit from various financial schemes, so he would like to see a level playing field in Ireland where the underlying price for biomethane is equal. This means introducing a government support scheme.

Despite this, the company is willing to commit the capital and enter the market as it currently stands.

“We know that if you have a market with a good source of feedstock and is encouraging grid injection, then the returns will come in time and will make sense,” he says.

CycleØ wants to work with one or more existing developers who are already at various stages in the planning process but the company is also prepared to work with new partners.

Agribusinesses or a dairy farmer with 400 cows-plus who can access extra grass silage is a candidate for them, he says.

Molke says that CycleØ is currently engaged in several discussions with Irish parties and aims to start construction of at least one plant by the end of the year.

“There is nothing like having a plant in place for people to come and see and understand how it works. We’ve experienced the same thing in other markets,” he says.

SHARING OPTIONS